Nitrogen-oxygen sensor ceramic chip core

A nitrogen and oxygen sensor and ceramic sheet technology, applied in the field of nitrogen and oxygen sensors, can solve problems such as sensor failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

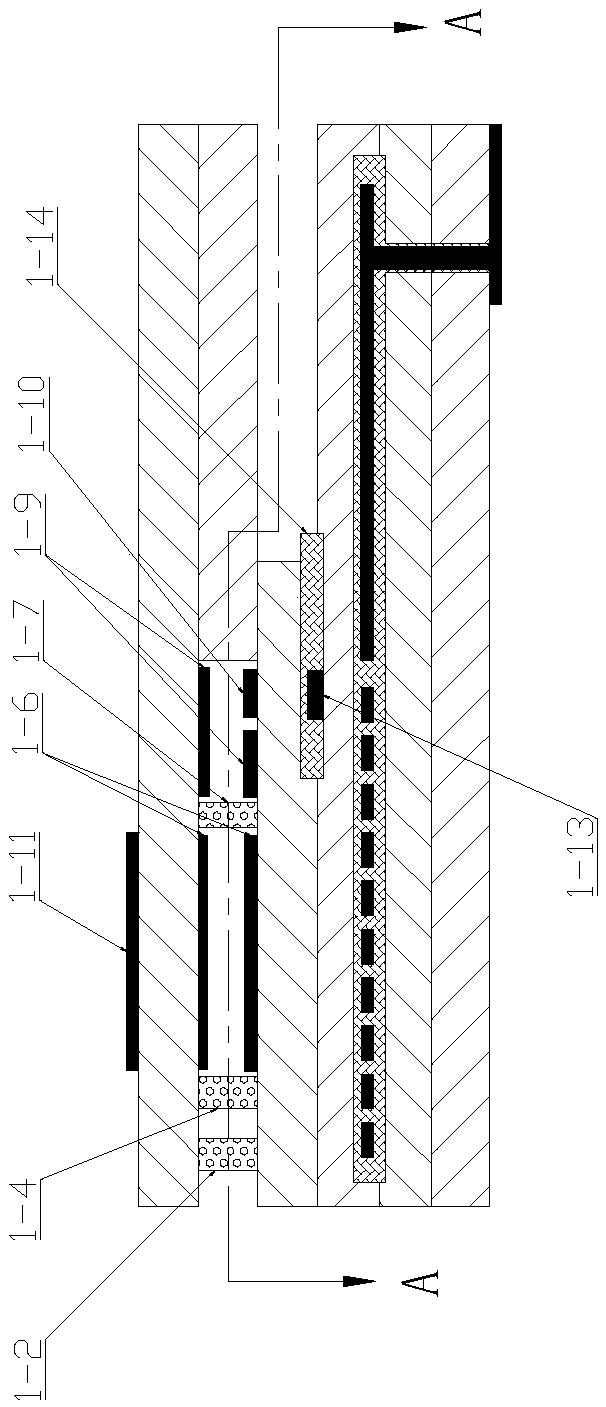

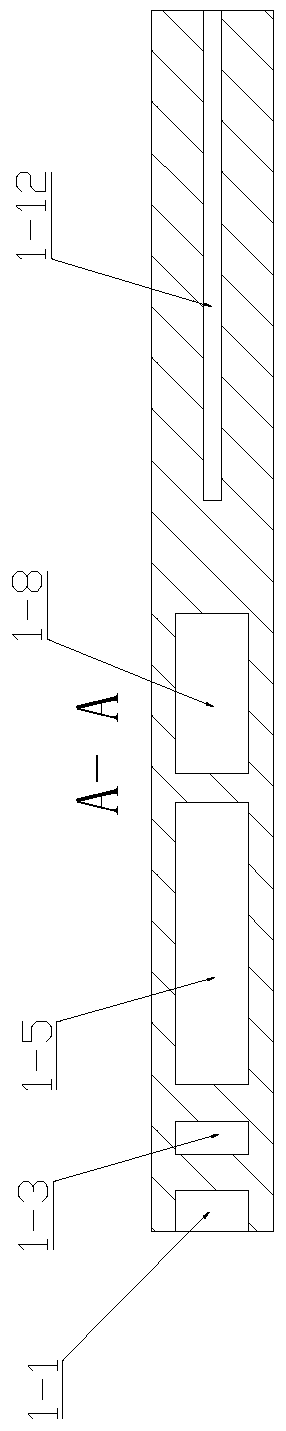

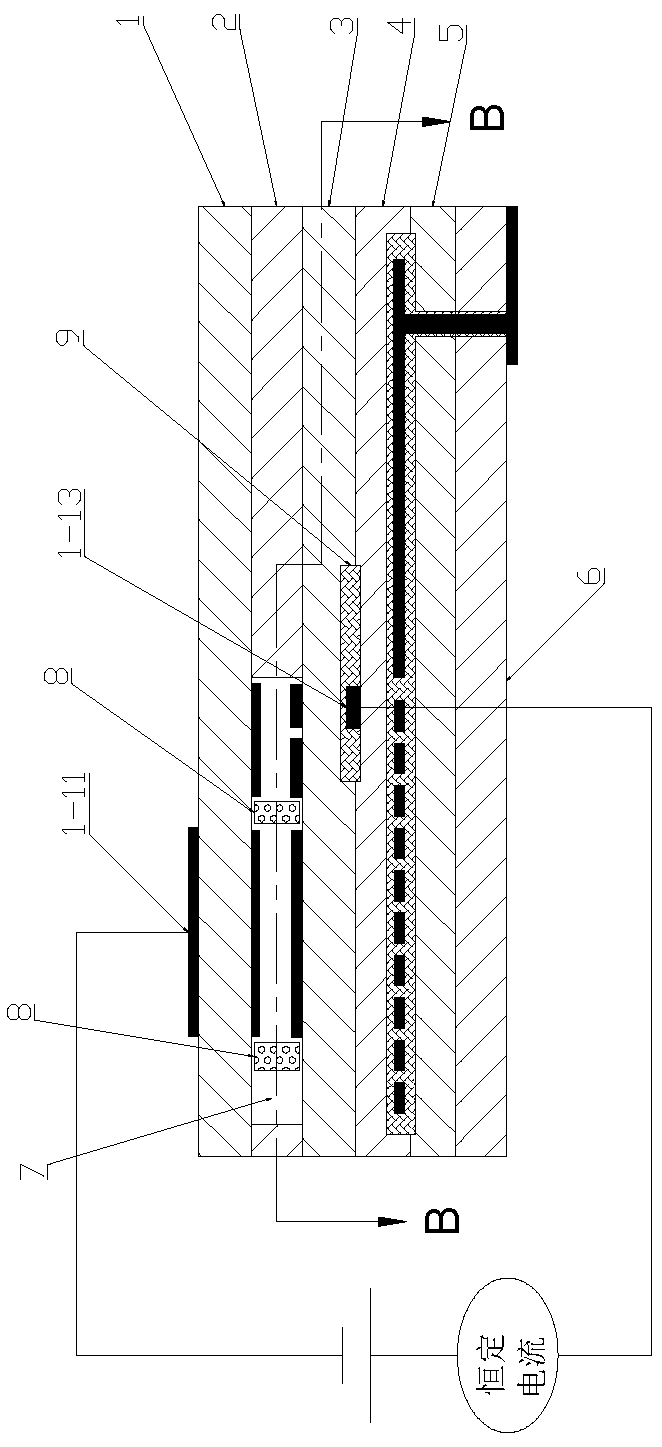

[0016] like image 3 , Figure 4 A nitrogen-oxygen sensor ceramic chip is shown, which includes a first substrate 1, a second substrate 2, a third substrate 3, a fourth substrate 4, a fifth substrate 5 and a sixth substrate arranged up and down. Sheet 6, external electrodes 1-11 are mounted on the outside of the first substrate 1, reference electrodes 1-13 are mounted between the third substrate 3 and the fourth substrate 4, and the middle of the second substrate 2 is sequentially provided with exhaust gas treatment The chamber 7, the first detection chamber 1-5 and the second detection chamber 1-8, the exhaust gas treatment chamber 7, the first detection chamber 1-7 and the second detection chamber 1-8 are provided with a gas diffusion barrier 8, and the exhaust gas treatment There are gas diffusion barriers 8 at the fronts of both sides of the cavity 7 and the front ends are closed; only a mounting cavity 9 for mounting the reference electrodes 1-13 is opened between the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com