Assembling equipment for automatic splitting and assembling of ceramic PCB

A technology for automatic board separation and assembly equipment, which is applied in the direction of assembling printed circuits with electrical components, electrical components, and printed circuit manufacturing. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

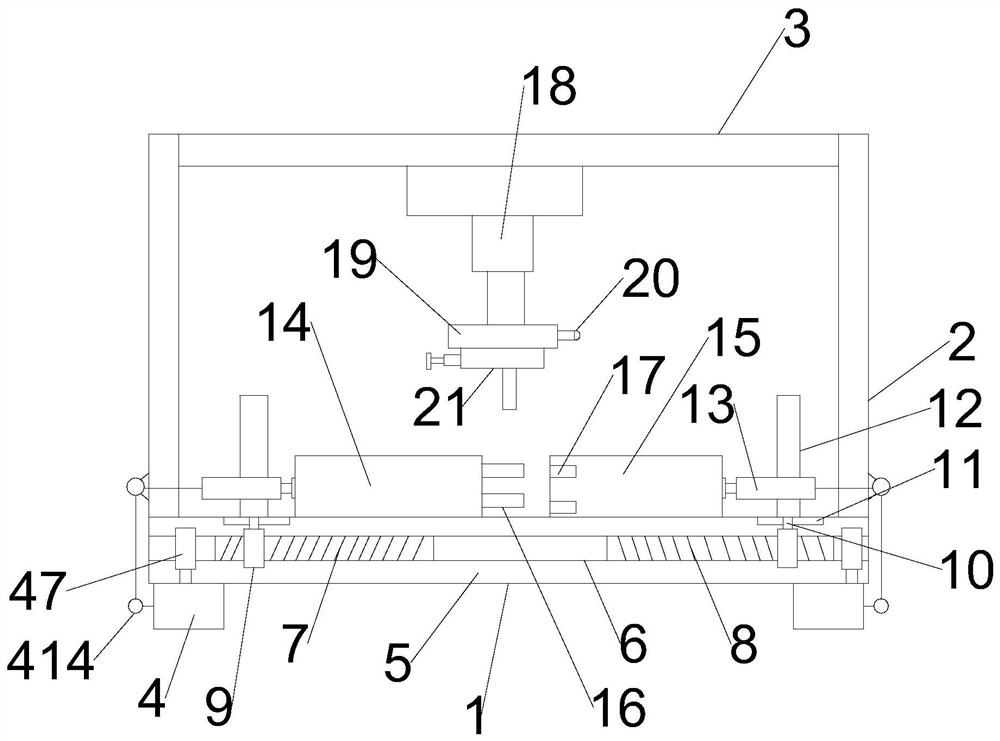

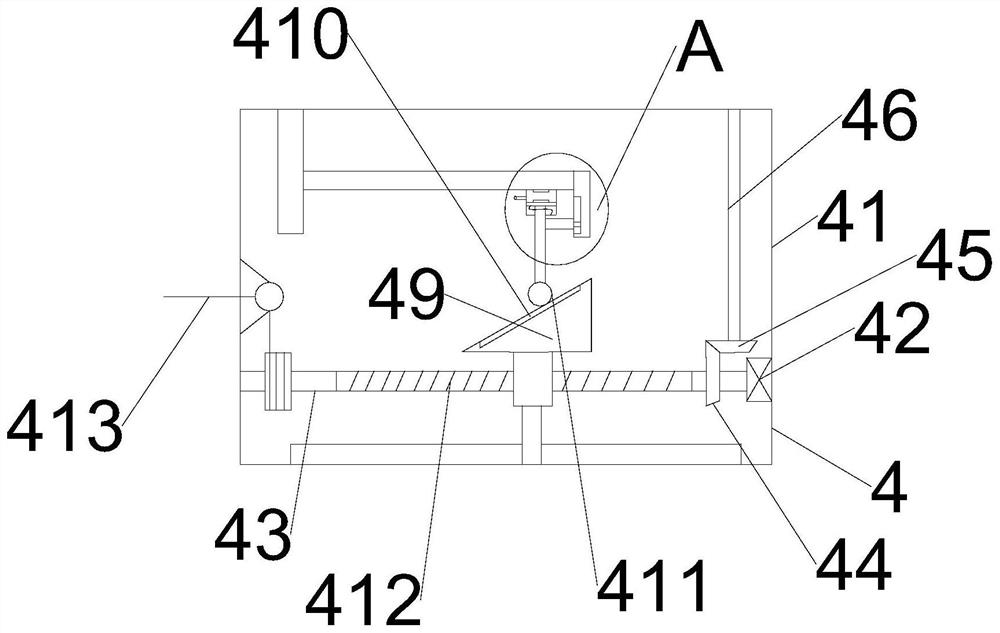

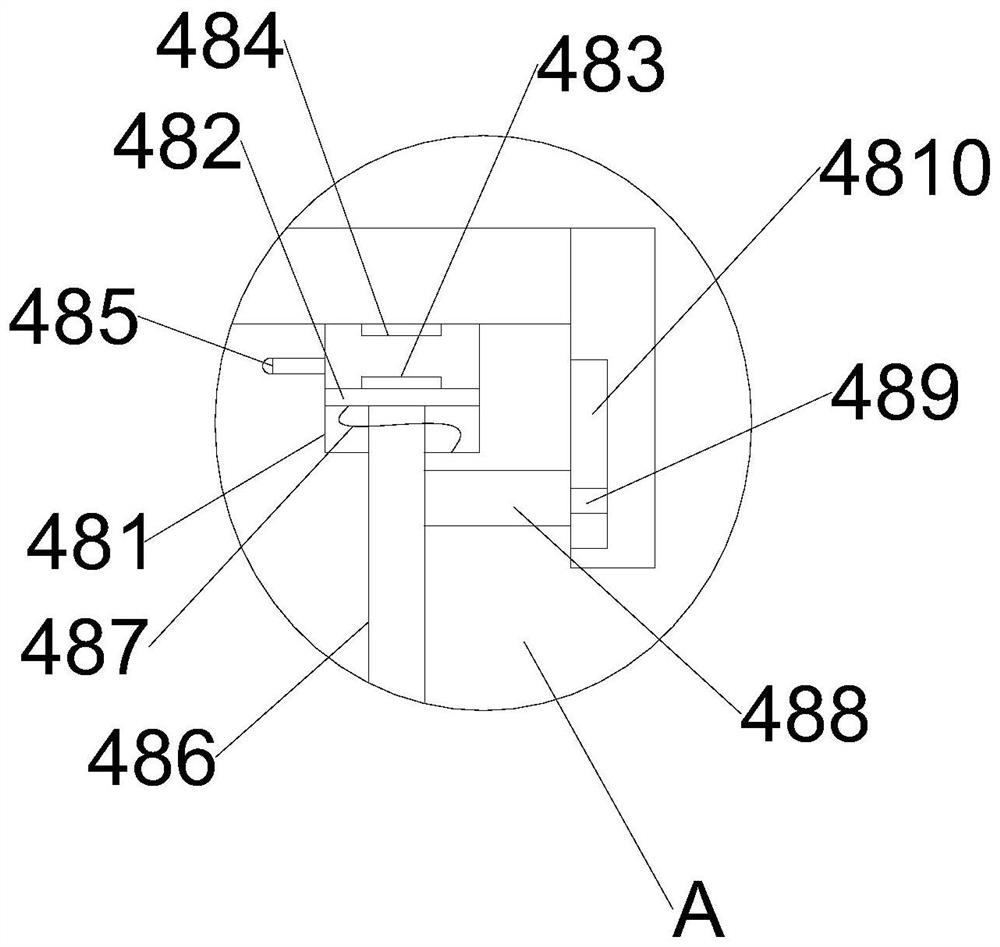

[0031] see Figure 1-7 In the present invention, the assembly equipment for ceramic PCB automatic sub-board assembly includes an assembly base 1, and the top of the assembly base 1 is symmetrically provided with supporting vertical columns 2, and the tops of the two supporting vertical columns 2 are jointly equipped with a supporting top plate 3, and the assembly The base 1 is provided with a drive assembly 4, and the installation cavity 5 of the assembled base 1 is provided with an installation shaft 6, and the installation shaft 6 is provided with a positive installation screw area 7 and a reverse installation screw area 8; the positive installation screw area 7, the reverse installation The threads of the screw zone 8 are opposite;

[0032] The positive installation screw area 7 and the reverse installation screw area 8 are threaded with a threaded moving block 9, and the threaded moving block 9 is provided with a passage post 10, and the passage post 10 passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com