Production process of polished matte pearl powder-added mobile phone backboard

A production process and pearlescent powder technology, which is applied in the printing process, printing and coating of special varieties of printed matter, and can solve the problem of inability to clearly display the texture and logo pattern of the texture layer, low coverage of reflected light, and poor three-dimensional layering and other issues, to achieve the effect of improving texture display effect, improving aesthetics, and good viewing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

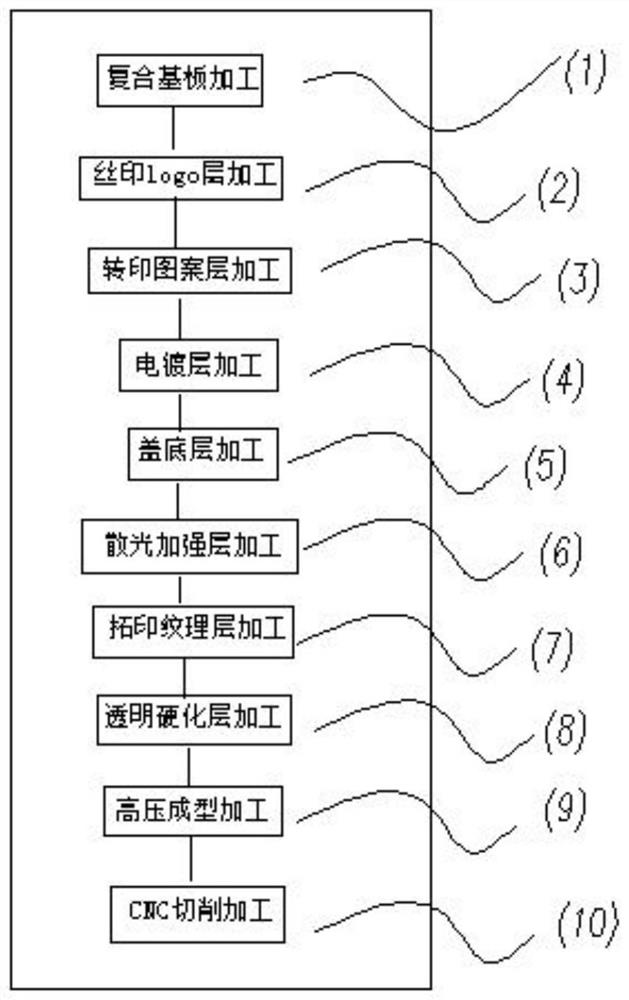

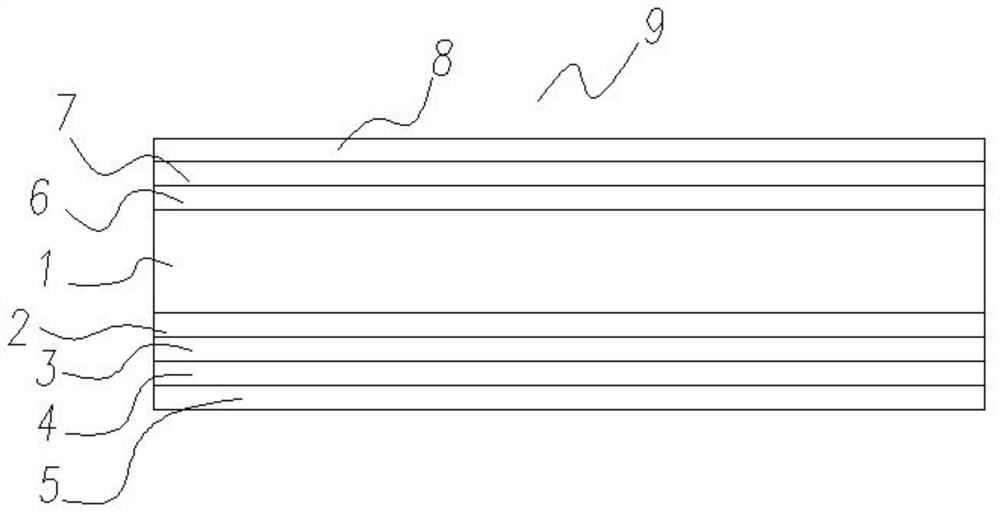

[0038] example, see appendix Figure 1 to Figure 3 , a production process for a mobile phone backplane with matte and pearlescent powder, which comprises the following steps:

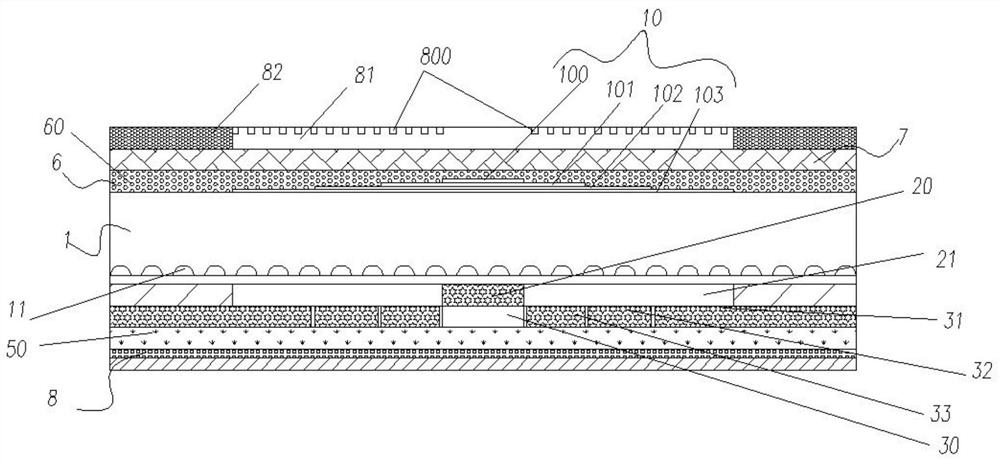

[0039] (1) Processing of the composite substrate 1: The transparent PMMA sheet is cut into a composite substrate 1 of a specified size by a cutting device, and the upper surface of the composite substrate 1 is processed by a CNC device with a stepped protrusion structure 10, and processing the astigmatism structure 11 on the lower surface of the composite substrate 1;

[0040] (2) Silk-screen printing process of the silk-screen logo layer 2: printing a transparent adhesive layer on the lower surface of the composite substrate 1, printing the logo pattern ink 20 and the transparent area 21 on the transparent adhesive layer to form a silk-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com