Filling and film sealing all-in-one machine for reagent cups

A reagent cup and integrated machine technology, applied in the field of reagent cup filling and sealing integrated machine, can solve the problems of increasing the risk of reagent contamination and oxidation, the impact of product quality, and the long time required, so as to improve work efficiency and product quality. , Reduce the probability of reagent contamination, the effect of high equipment operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

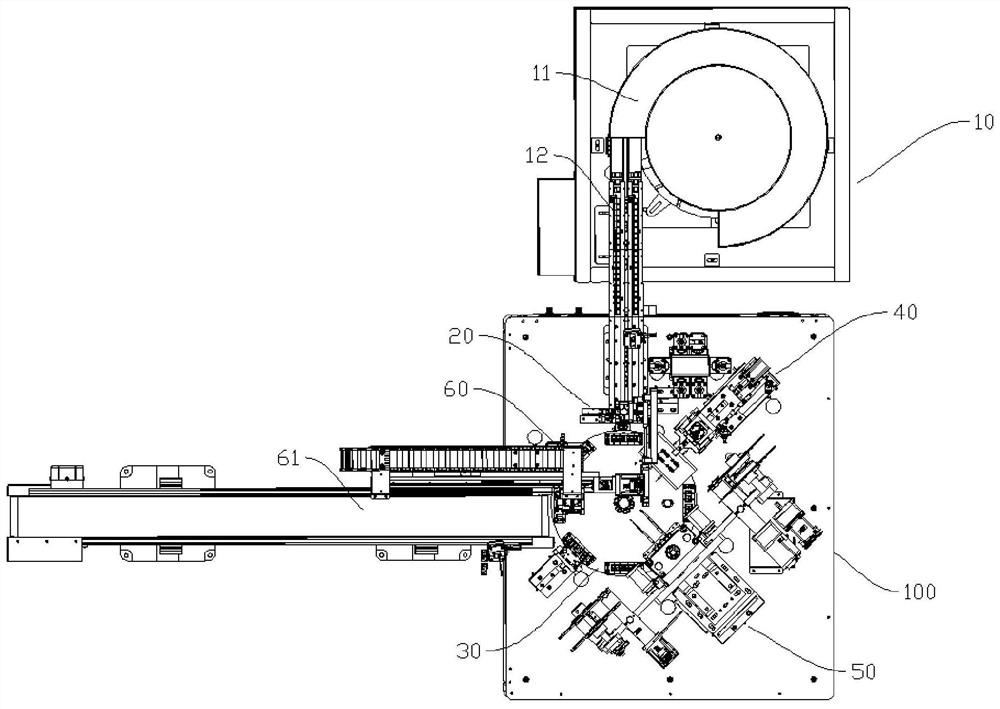

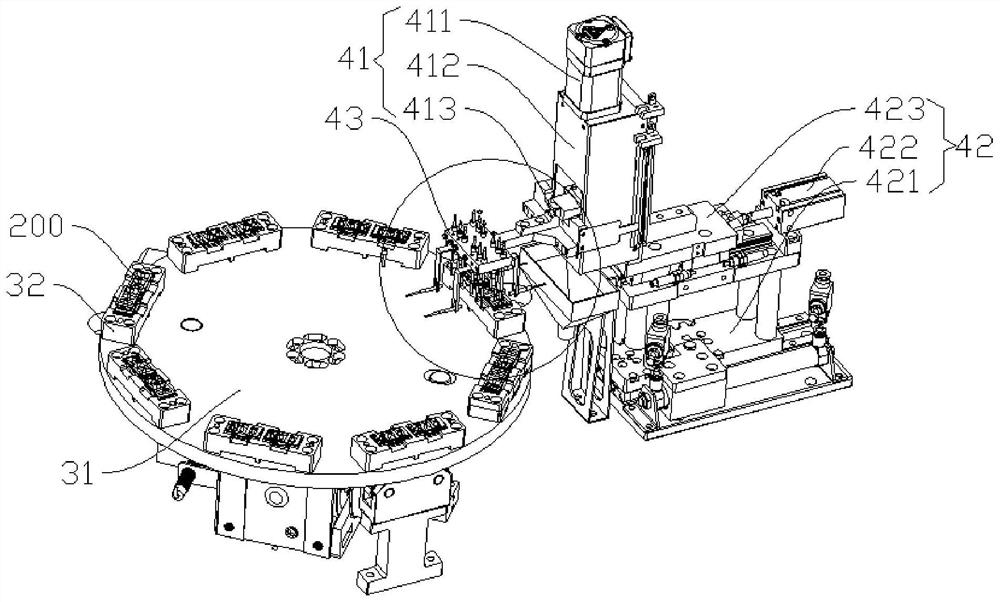

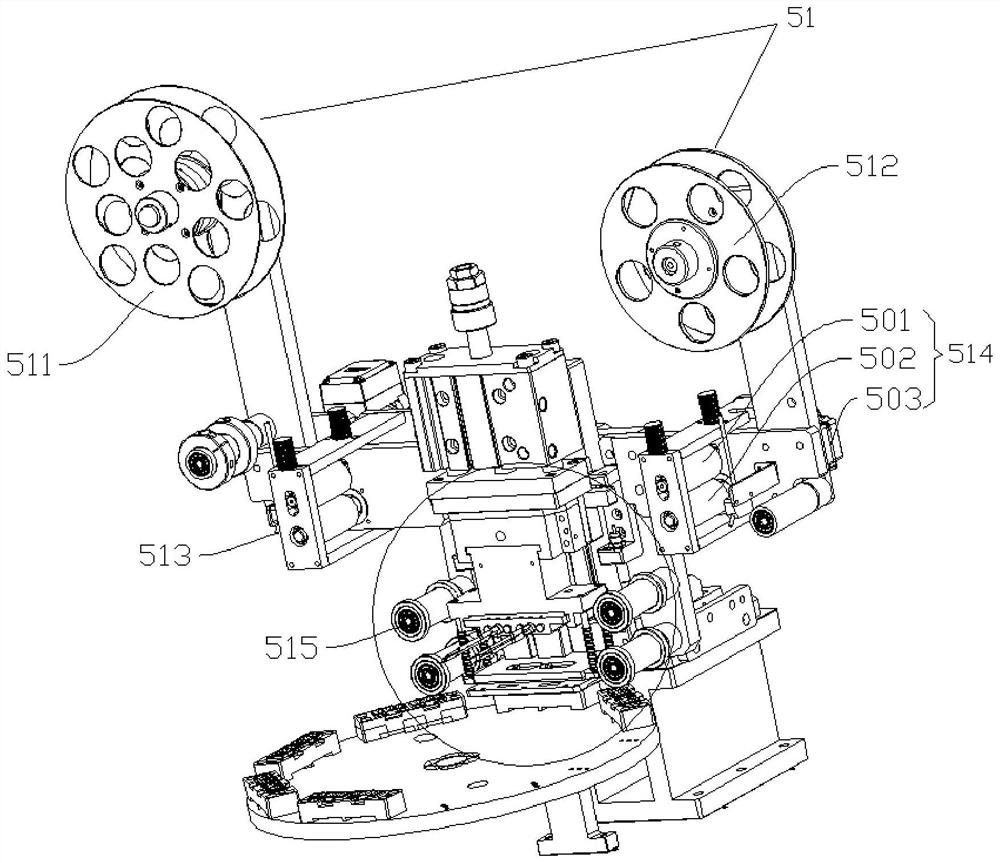

[0029] Aiming at the situation that the existing reagent cup filling and sealing film cannot be completed in an integrated manner, the present invention develops an integrated reagent cup filling and sealing film machine. The invention specifically provides a reagent cup filling and sealing machine, please refer to Figure 1-3 , the reagent cup filling and sealing machine includes: a vibration plate device 10, a feeding device 20, a turntable device 30, a filling device 40, a film sealing device 50 and a discharge device 60; the feeding device 20, the turntable device 30. The filling device 40, the film sealing device 50 and the discharge device 60 are all installed on an installation platform 100, and the feeding device 20, the filling device 30, the film sealing device 40 and the discharge device 50 are all around the The turntable device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com