Double-opening type interlayer plastic bottle

A technology of plastic bottles and double openings, applied in the field of plastic bottles, can solve the problems of single function and limit the application of plastic bottles, and achieve the effect of improving the applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

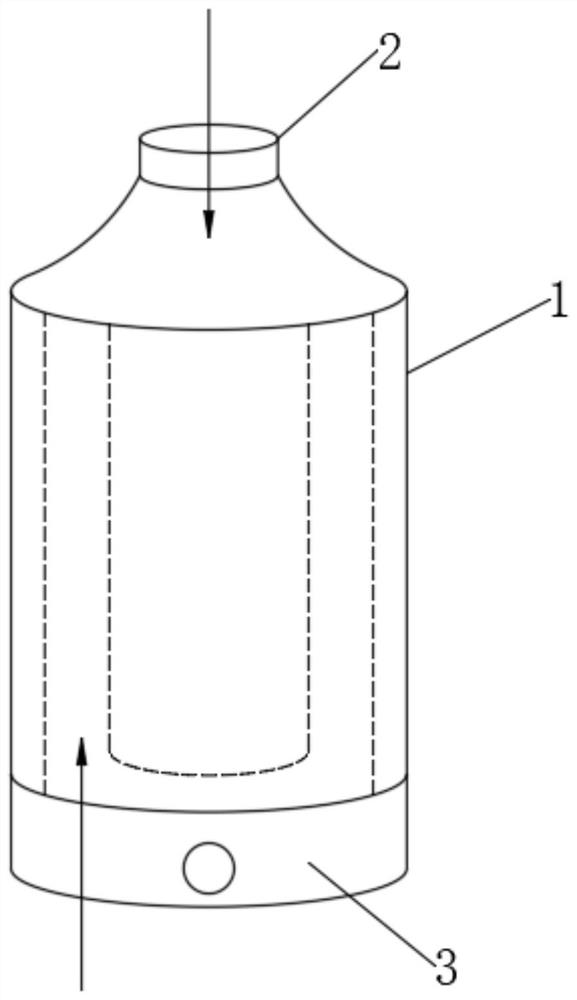

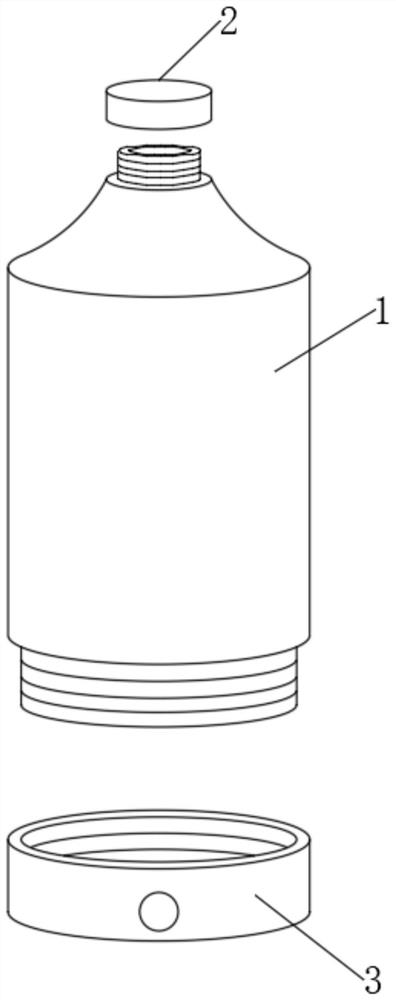

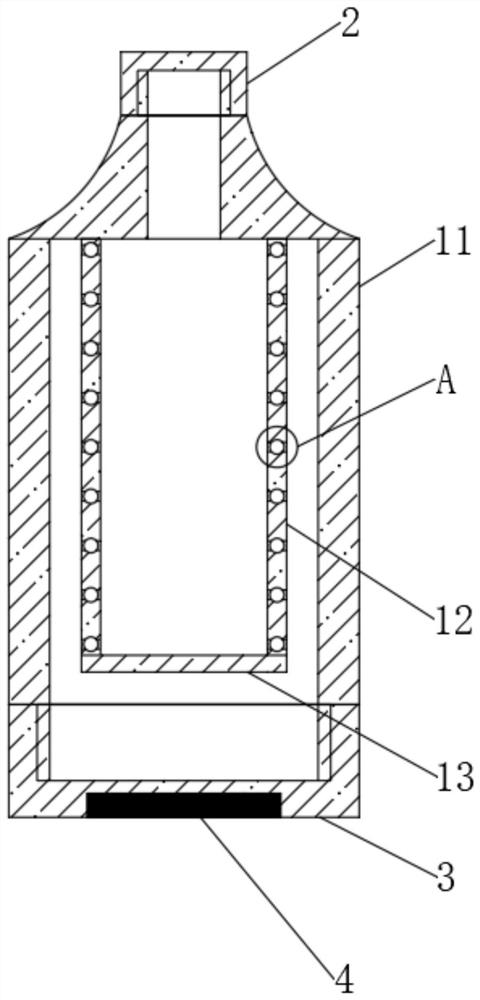

[0042] see Figure 1-4 , a double-opening sandwich plastic bottle, including a bottle body 1, the bottle body 1 includes an outer bottle body 11, an inner isolation sleeve 12, and a thermal insulation base plate 13, the upper and lower ends of the outer bottle body 11 are open structures, and the inner isolation sleeve 12 is fixed. Connected to the inner end of the outer bottle body 11 and communicated with the opening at the upper end, the thermal insulation bottom plate 13 is fixedly connected to the end of the inner spacer 12 close to the lower opening, the outer bottle body 11 and the inner spacer 12 are concentrically arranged and left with a cavity, the outer The upper opening of the bottle body 11 is threadedly connected with an upper cover 2, the lower end of the outer bottle body 11 is threadedly connected with a lower cover 3, the inner end of the lower cover 3 is inlaid with an electromagnet 4, and the inner end of the inner isolation sleeve 12 is inlaid and connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com