A method and device for preparing high borosilicate glass by float method

A high borosilicate glass and high borosilicate technology, applied in glass production, glass furnace equipment, glass manufacturing equipment and other directions, to achieve the effect of improving the life of the kiln, reducing the generation of defects, and reducing glass defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

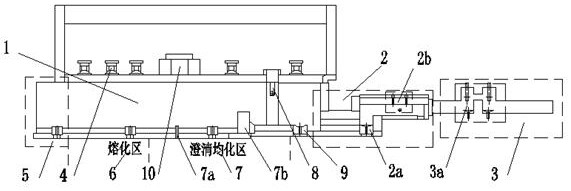

[0033] A method for preparing high borosilicate 3.3 float glass, which adopts the following device: comprising a furnace body (1), a feeding system (2) and a platinum channel system (3) which are connected in sequence;

[0034] The bottom of the furnace body (1) is evenly distributed with 15 groups of heating electrodes, which are sequentially divided into a feeding area (5), a melting part (6), a clarification and homogenization area (7) from the bottom of the furnace body (1), and the clarification and homogenization A liquid glass device (9) is arranged behind the chemical zone (7); combustion lances (4) (fuel is liquid and / or gaseous fuel) are arranged on both sides of the furnace body (1), and the combustion lances are evenly distributed in the kiln. On both sides of the body (1), there are 15 pieces on each side, and a kiln flue (10) is arranged on the inner side of the furnace body (1) to take away some of the volatilized batch materials and the flue gas formed by combus...

Embodiment 2

[0045] A method for preparing high borosilicate 4.0 float glass, using the device described in Embodiment 1, includes the following steps:

[0046] (1) In terms of weight percentage, the composition of the borosilicate glass batch is as follows: 35% of the high borosilicate 3.3 broken glass produced by our company, 65% of the batching material, and the batching material is composed of the following raw materials: 72% of silica sand, hydrogen Alumina 7%, borax 13%, boric acid 3%, soda ash 2%, potassium carbonate 1%, sodium chloride 1%, limestone 1%; ) for melting, the fuel is natural gas, and the combustion-supporting gas is high-purity oxygen. By adjusting the natural gas flow rate of the burner to 480Nm3 / h, the temperature of the upper part of the molten glass is adjusted, and the temperature of the bottom of the molten glass pool is adjusted by adjusting the power of the electrode group. The temperature of the upper part of the melting part (6) is 1600°C, and the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com