A Low Dilution Ratio Double Filler Tig Overlay Welding Process and Its Application

A technology of dilution rate and wire filling, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of reduced efficiency, increased welding equipment cost, large volume, etc., and achieve the effect of increased utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

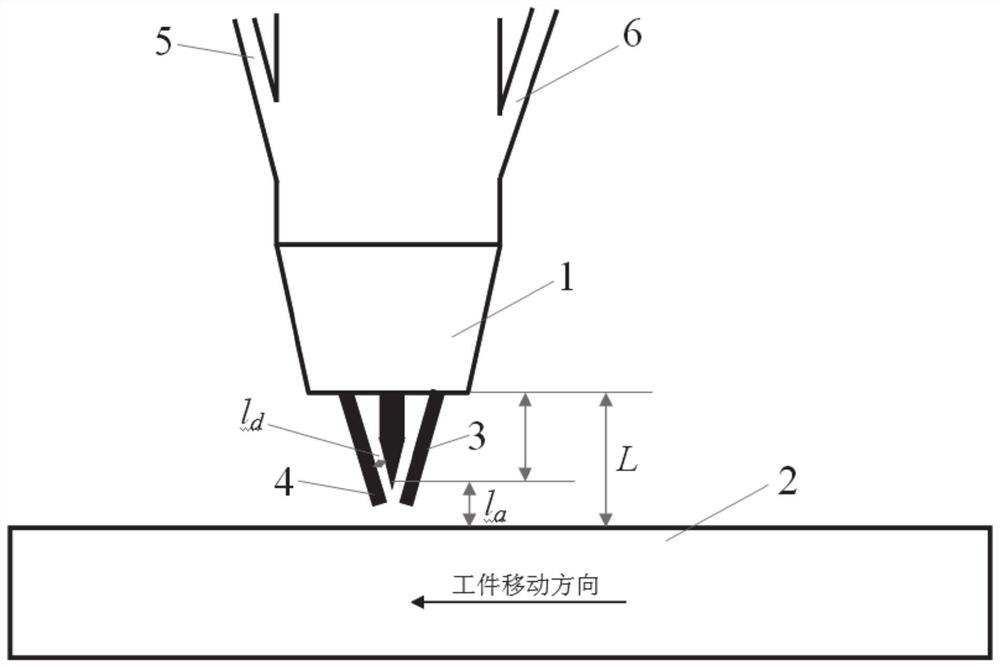

[0043] refer to figure 1 , a low-dilution rate double filler wire TIG surfacing process, including steps:

[0044] (1) Pre-treatment before welding: use 4mm thick low-carbon steel plate as the welding workpiece 2, clean the area to be surfacing and the surrounding area with a width of not less than 20mm, and remove oil stains and oxide films.

[0045] (2) Workpiece clamping: clamp the two workpieces processed in step (1) on a worktable capable of moving the workpiece at a constant speed at any speed between 0.1 and 3.0 m / min.

[0046] (3) Welding preparation: fix the welding torch on the upper part of the workpiece to be welded in step (2) according to the way that the two welding wires are arranged in front and back along the welding direction, and the vertical distance L between the nozzle 1 of the welding torch and the workpiece 2 is 7mm , the diameter of the welding wire is 1.2mm, the diameter of the tungsten pole is 3.2mm, the taper angle at the end is 40°, and the inclu...

no. 2 example

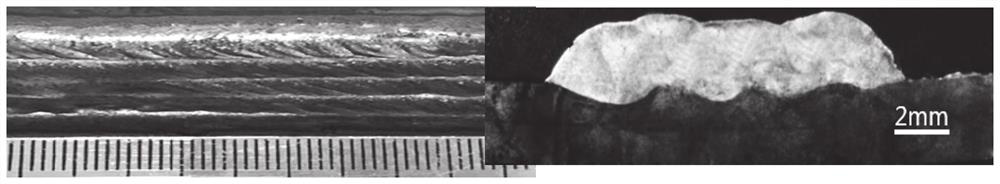

[0082] The same process as the first embodiment is used for surfacing welding. The purpose of this embodiment is to test the droplet transition and molten pool shape during the surfacing process of the workpiece. The results are as follows Figure 9 shown. It can be seen that the front and rear welding wires are all in contact transition, the molten pool under the arc continues to exist, the difference in the size of the molten droplet between the front and rear welding wires is small, and the molten droplet metal that alternately transitions into the molten pool quickly disperses into the molten pool, and the transition process and the molten pool are stable , The weld is well formed.

no. 3 example

[0088] refer to figure 1 , a low dilution rate double filler wire TIG surfacing process, including the following steps:

[0089] (1) Pre-welding pretreatment: use 6mm thick low-carbon steel plate as the welding workpiece 2, clean the area to be surfacing and the surrounding area of not less than 20mm to remove oil stains and oxide films.

[0090] (2) Workpiece clamping: clamp the two workpieces processed in step (1) on a workbench capable of moving the workpiece at a constant speed at any speed between 0.1-3.0m / min.

[0091] (3) Welding preparation: fix the welding torch on the upper part of the workpiece to be welded in step (2) according to the way that the two welding wires are arranged in front and back along the welding direction. The vertical distance L between the nozzle 1 of the welding torch and the workpiece 2 is 9mm. The diameter of the tungsten pole is 1.2mm, the diameter of the tungsten pole is 3.2mm, the taper angle at the end is 40°, the angle between the two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com