A tial/tc4 electron beam melting and brazing method with an alloy intermediate layer added

An electron beam welding and intermediate layer technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of material cracking, increasing cracking tendency, reducing joint plasticity, etc., so as to improve crack resistance and optimize mechanical properties. , the effect of improving the strength of the joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

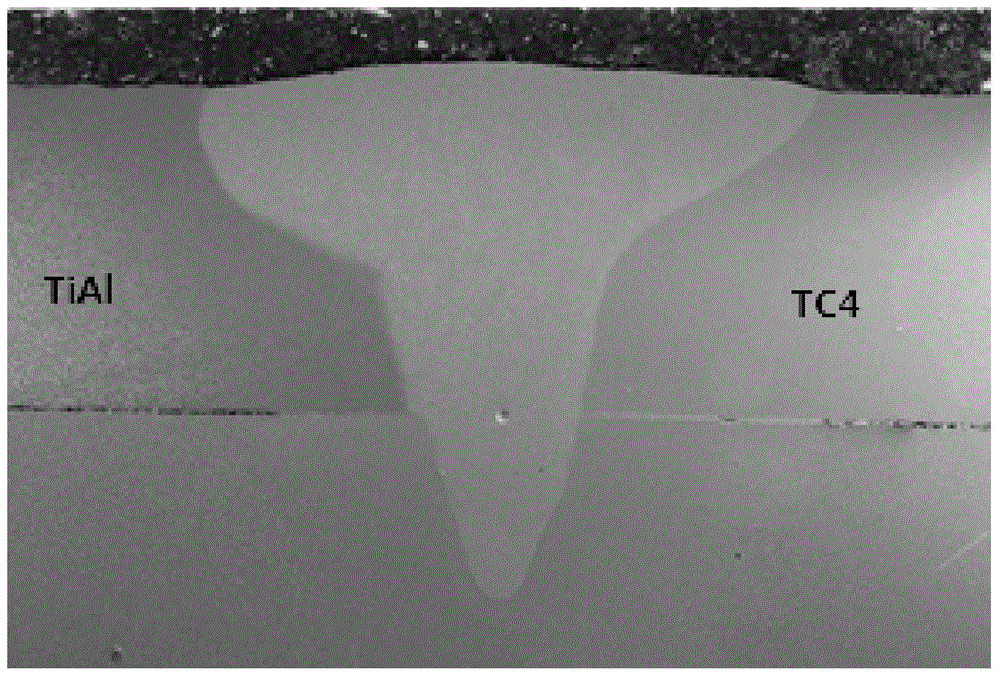

[0038] (1) The base metal to be welded is cleaned before welding, and the oil stain and oxide layer on the surface of the material are removed by physical and chemical methods. The base metal is TiAl and TC4 plate, and the thickness of the plate is 1.5mm.

[0039] (2), prepare the intermediate layer alloy by wire cutting, the intermediate layer alloy elements Nb, Ni, the Nb foil is 1 layer, and the Ni foil is 1 layer. The foil is spot welded and positioned by a spot welding machine, and then the intermediate layer Spot welding to the welding surface of TC4 base metal; the thickness of each layer of Nb foil is 100 μm, and the thickness of each layer of Ni foil is 100 μm.

[0040] (3) Fix the workpiece with a fixture to ensure the tight connection between TC4 and TiAl;

[0041] (4) Put the workpiece into the vacuum chamber of the electron beam welding machine and start vacuuming;

[0042] (5), when the vacuum degree reaches 5×10 -2 Pa, adjust the electron beam welding process ...

Embodiment 2

[0046] (1) The base metal to be welded is cleaned before welding, and the oil stain and oxide layer on the surface of the material are removed by physical and chemical methods. The base metal is TiAl and TC4 plate, and the thickness of the plate is 1.5mm.

[0047] (2) Prepare the intermediate layer alloy by wire cutting, the intermediate layer alloy elements Nb, Ni, the Nb foil is 2 layers, and the Ni foil is 1 layer. Use a spot welding machine to spot weld the foil and then spot weld the intermediate layer To the welding surface of TC4 base metal; the thickness of each layer of Nb foil is 100 μm, and the thickness of each layer of Ni foil is 100 μm.

[0048] (3) Fix the workpiece with a fixture to ensure the tight connection between TC4 and TiAl;

[0049] (4) Put the workpiece into the vacuum chamber of the electron beam welding machine and start vacuuming;

[0050] (5), when the vacuum degree reaches 5×10 -2 Pa, adjust the electron beam welding process parameters to prepar...

Embodiment 3

[0054] (1) The base material to be welded is cleaned before welding, and the oil stain and oxide layer on the surface of the material are removed by physical and chemical methods. The base material is TiAl and TC4 ring, with a thickness of 2mm.

[0055] (2) Prepare the intermediate layer alloy by wire cutting, the intermediate layer alloy elements Nb, Ni, the Nb foil is 2 layers, and the Ni foil is 1 layer. Use a spot welding machine to spot weld the foil and then spot weld the intermediate layer To the welding surface of TC4 base metal; the thickness of each layer of Nb foil is 100 μm, and the thickness of each layer of Ni foil is 100 μm.

[0056] (3) Fix the workpiece with a fixture to ensure the tight connection between TC4 and TiAl;

[0057] (4) Put the workpiece into the vacuum chamber of the electron beam welding machine and start vacuuming;

[0058] (5), when the vacuum degree reaches 5×10 -2 Pa, adjust the electron beam welding process parameters to prepare for weldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com