Method for welding minor-diameter nozzle and aluminum alloy thin-walled structure

A thin-walled, small-diameter tube technology, used in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult to meet requirements, large heat-affected zone, low energy density, etc. Accurate parameter control, low line energy and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

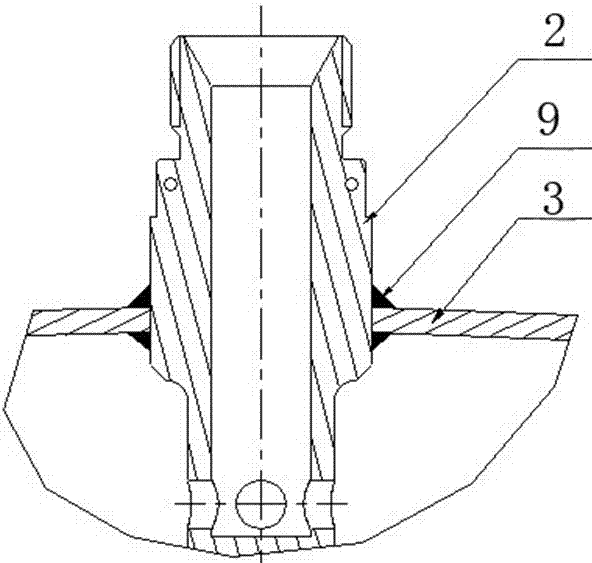

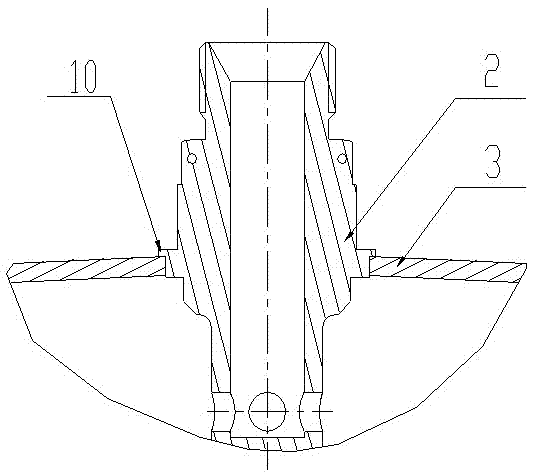

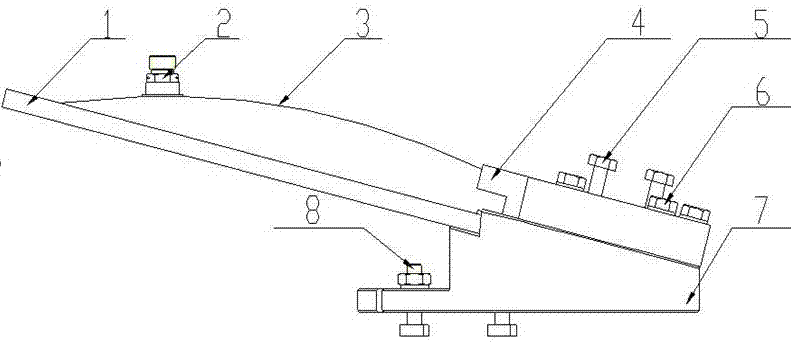

[0034] Example 1 as figure 2 and image 3 As mentioned above, the welding method of the small-diameter nozzle and the aluminum alloy thin-walled structure of the present invention is characterized in that: it adopts the following steps to realize:

[0035] 1) Process the aluminum alloy thin-walled structure 3, the aluminum alloy thin-walled structure 3 is spherical crown, the ring 1 is installed on the edge of the spherical crown, and the spherical crown of the aluminum alloy thin-walled structure 3 is processed to assemble a small diameter Mounting hole for Nozzle 2.

[0036] First install the ring 1 on the edge of the aluminum alloy thin-walled structure 3, so that the entire aluminum alloy thin-walled structure 3 forms a ring shape, so that the aluminum alloy thin-walled structure 3 has a certain rigidity, which is convenient for processing on the aluminum alloy thin-walled structure 3 The installation holes are convenient for welding operations, and at the same time, it...

Embodiment 2

[0047] Embodiment 2 is similar to Embodiment 1, except that in step 4), the radius of the boss 10 inside the spherical cap is 4mm larger than the radius of the mounting hole, and the thickness is 1.0mm, which can meet the requirements of providing sufficient weld leakage for Dressing and grinding, while ensuring that the boss 10 is self-melting. According to actual needs, the radius of the boss (10) is 3-4 mm larger than the radius of the mounting hole, and the thickness of the boss (10) is 0.5-1 mm, so as to ensure sufficient welding leakage allowance and facilitate the boss 10 Self-melting.

[0048] In the welding method of the small-diameter nozzle and the thin-walled aluminum alloy structure of the present invention, step 1) and step 2) can be carried out at the same time, or the operation of step 2) can be carried out first, and then the operation of step 1) can be carried out. The essence is Same, all are to the processing of small-diameter nozzle 2 and aluminum alloy t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com