Heat storage type organic fertilizer preparation excrement drying line

A drying line and organic fertilizer technology, which is applied in heat storage equipment, organic fertilizer, drying, etc., can solve the problems of large fluctuations in solar energy and poor precision of drying process control, and achieve sterilization and protection of effective nutrients. The effect of widely promoting and using and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

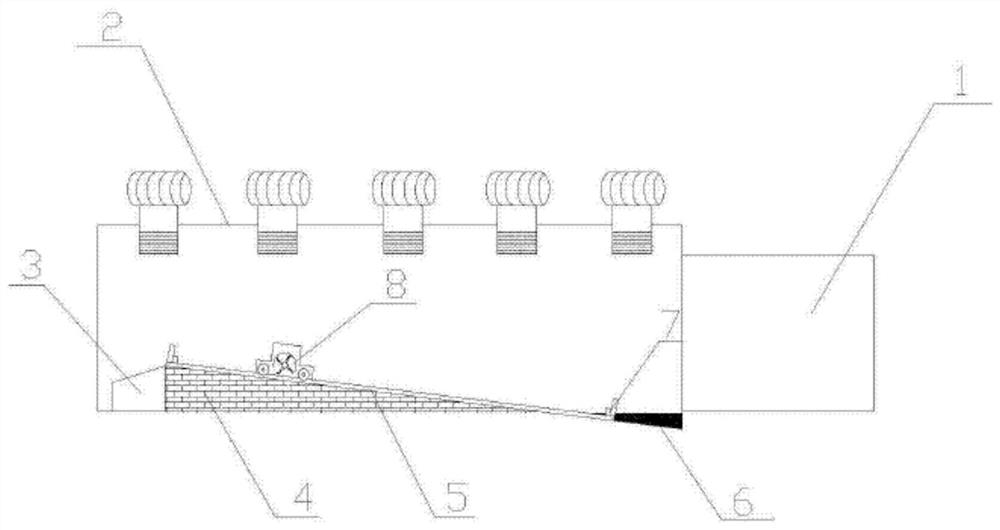

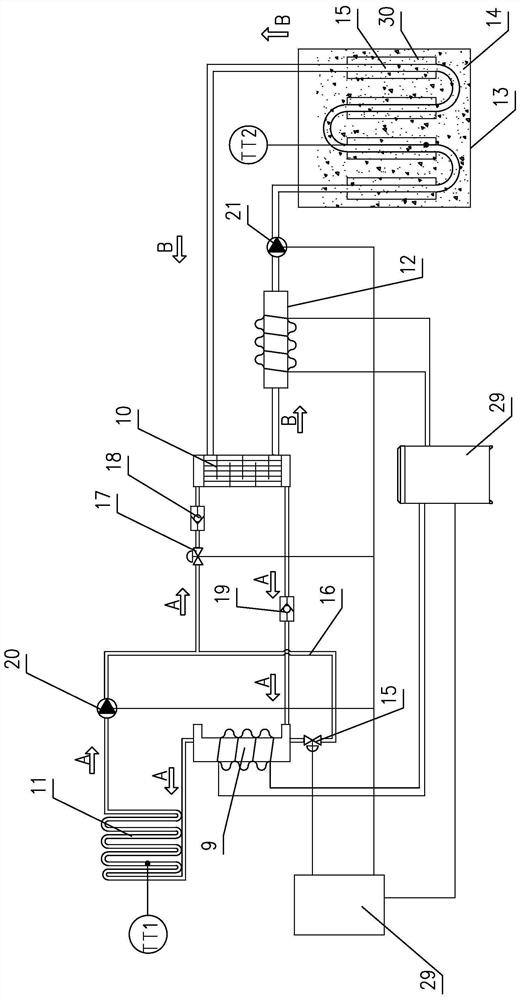

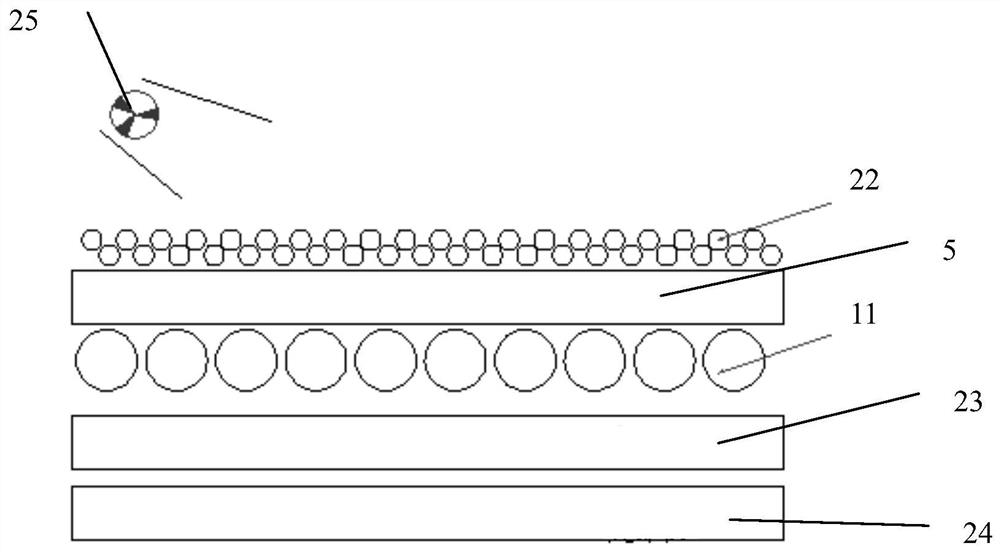

[0030] Such as figure 2As shown, it is a heat storage type organic fertilizer preparation manure drying line of the present invention, including a control system 29, a track 5 for transporting fermented chicken manure, a heat storage circuit and a heat supply circuit, and chicken manure is realized during transportation. drying treatment, the heat supply circuit is mainly connected by the first heater 9 and the heat exchanger 10 through pipelines, and there is a circulation circuit in which the heat exchange medium flows. In this embodiment, the heat exchange medium is water A, and the heat supply The part of the pipe section of the circuit located in front of the first heater 9 is the heating pipe 11 arranged under the track 5; There is a circulation circuit where the heat transfer medium flows. In this embodiment, the heat transfer medium is heat transfer oil B, that is, the heat exchanger 10 is a common component of the heat storage circuit and the heat supply circuit. The...

Embodiment 2

[0039] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that a photovoltaic system 26 is added, and the first heater 9 and the second heater 12 respectively use electromagnetic heaters. In other embodiments, the heaters can also use resistors A heater or an electrically driven heat pump, the power output terminals of the photovoltaic system 26 are respectively connected with the electromagnetic control box of the control system 29 and the grid 27, the control system 29 is connected with the grid 27, and the control system 29 is the first electromagnetic heater and the second electromagnetic heater The device provides power.

[0040] see Figure 5 , use grid valley electricity E to store heat during valley electricity period, and use photovoltaic system to store heat when the sun is shining. The power generation C of photovoltaic system 26 can store heat through heat storage device 13 and supply heat F to heating circuit 31 for use. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com