Aluminum alloy corrugated plate-ECC plate combined anti-collision guardrail

An anti-collision guardrail and aluminum alloy technology, which is applied to roads, buildings, road safety devices, etc., can solve the problems of large variation in impact resistance with service life, heavy quality of anti-collision guardrails, and heavy pollution, so as to reduce maintenance costs. , the effect of excellent impact stiffness requirements and strong energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

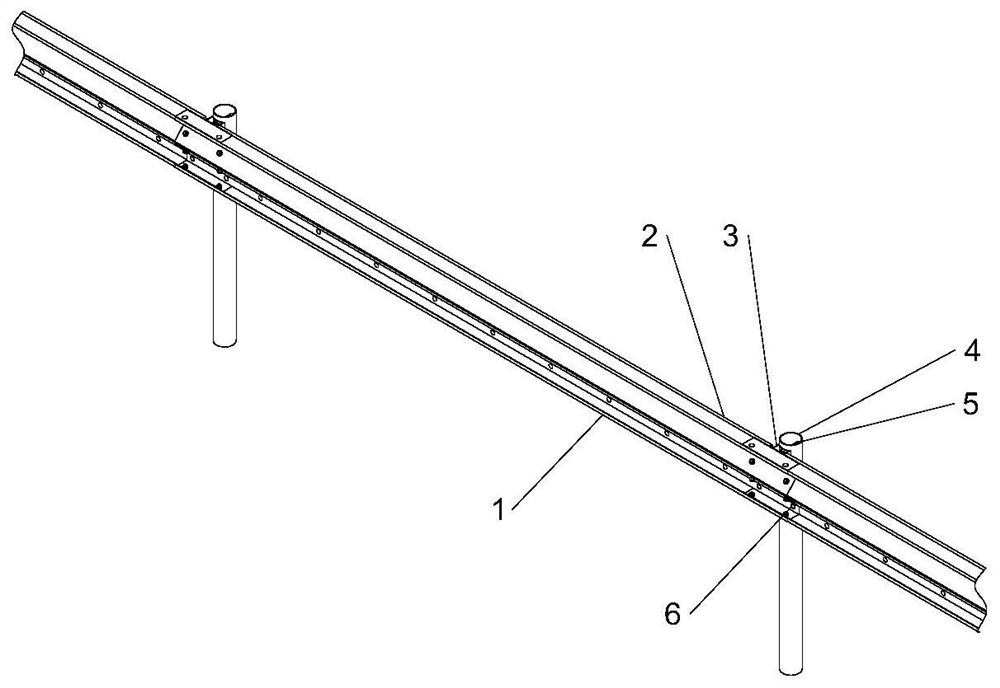

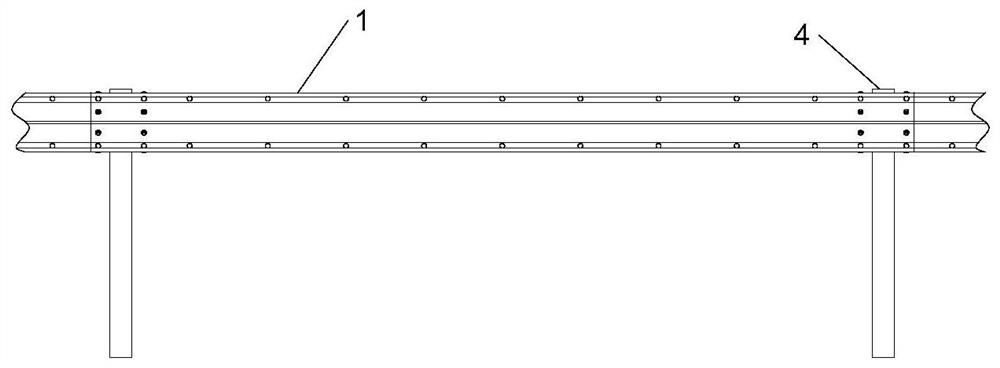

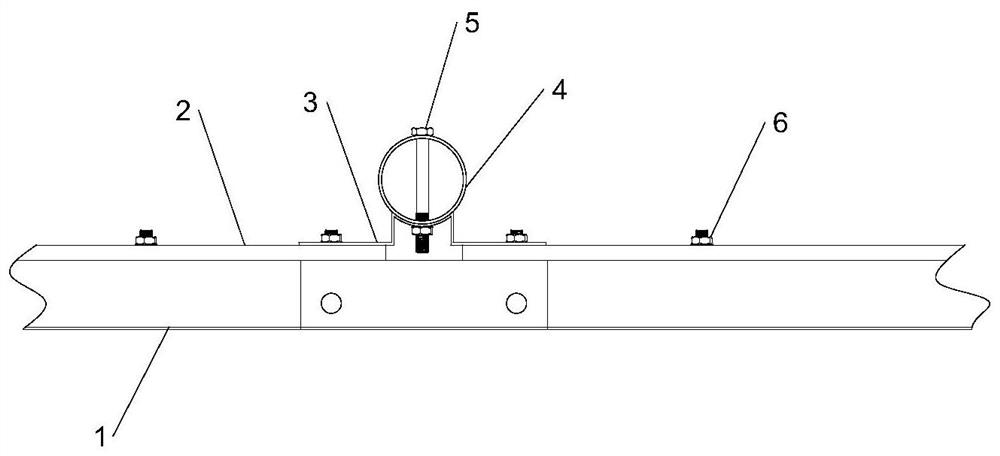

[0027] Such as figure 1 , 2 , 3, and 4, this example provides an aluminum alloy corrugated board-ECC board combined anti-collision guardrail for expressway, including aluminum alloy corrugated board (1), ECC energy dissipation board (2), L-shaped aluminum An alloy bracket (3), an aluminum alloy-concrete composite column (4), a connecting bolt (5), a connecting screw (6) and a pre-embedded cap (7).

[0028] Such as Figure 5As shown, the aluminum alloy corrugated plate (1) is made of 6082 series aluminum alloy, including connecting holes (1a), mounting holes (1b), upper and lower flanges (1c), troughs (1d) and crests (1e). The connection hole (1a) is used to insert the connection screw (6) to connect with another aluminum alloy corrugated plate (1), and is located on the upper and lower flanges (1c) and the two slopes of the crest (1e) of the aluminum alloy corrugated plate (1), Each end contains 8 pieces, and each end has 2 pieces on the upper and lower flanges (1c), which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com