Corrugated steel plate coated cold-formed thin-walled shear wall with self-resetting energy dissipation support

A technology of energy-dissipating support and corrugated steel plate, which is applied in the direction of walls, building types, buildings, etc., can solve the problems of general, self-resetting characteristics of dissipated earthquake energy, and inapplicability, so as to facilitate structure reset, facilitate assembly, and reduce construction waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

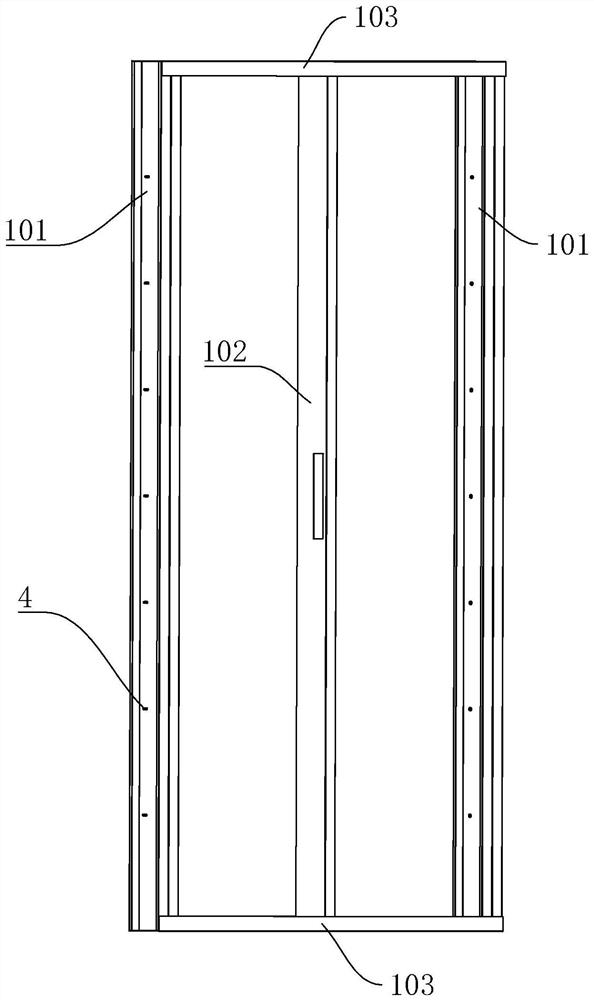

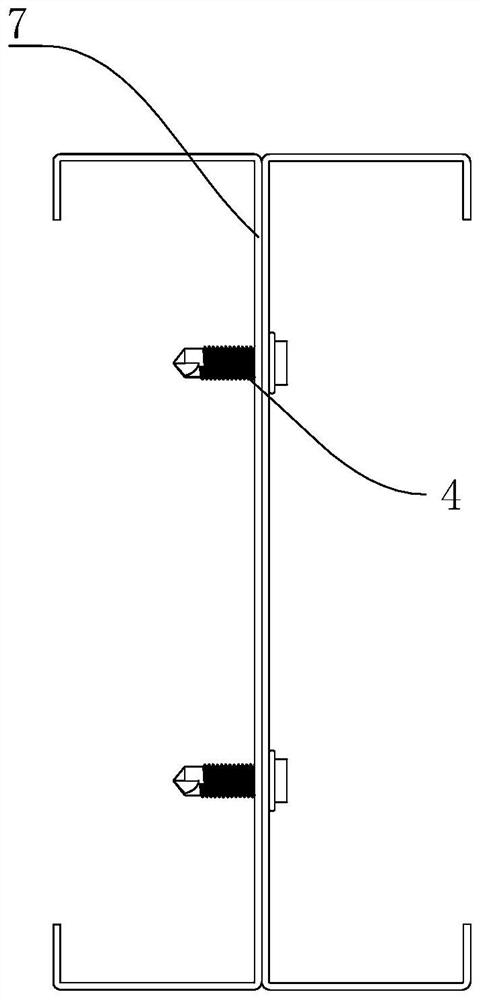

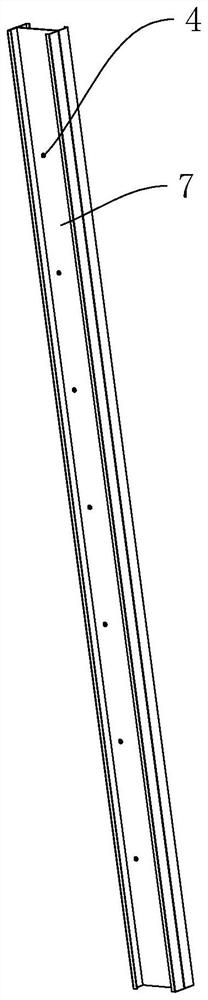

[0037] like Figure 1-11 As shown, a corrugated steel plate cladding cold-formed thin-walled shear wall with self-resetting energy-dissipating support includes a wall panel 6, and the wall panel 6 is provided with a steel wall skeleton 1, and the steel wall The skeleton 1 is provided with a self-resetting energy-dissipating support assembly 2 and an anti-pullout member 3. One end of the anti-pullout member 3 is connected to the steel wall skeleton 1, and the other end is connected to the self-resetting energy-dissipating support assembly 2. The steel wall Self-tapping screws 4 are provided on the wall frame 1, turnbuckle bolts 5 are arranged between the self-resetting energy-dissipating support assembly 2 and the pull-out member 3, and the self-resetting energy-dissipating support assembly 2 is mounted on the steel wall frame 1. Arranged obliquely inside to form a cross X shape or arranged obliquely on both sides of the steel wall skeleton 1 to form a figure-eight.

[0038] I...

Embodiment 2

[0056] combine Figure 12 As shown, the self-resetting energy-dissipating support assembly 2 is connected with the steel wall framework 1, and the pull-out member 3 added on the steel wall framework 1 is connected with the bearing 212 on the self-resetting energy-dissipating support 2 with a turnbuckle 5 . Self-resetting energy-dissipating supports 2 are arranged obliquely on both sides of the central column on the steel wall skeleton 1, forming a figure-eight shape.

[0057] In this embodiment, the eight-shaped support structure is adopted to enhance the structural strength between the steel wall frame 1, the side column 101 and the wall panel 6, and enhance the bearing capacity and rigidity, which can be applied to different scenarios and has strong practicability.

[0058] The working principle of the present invention is:

[0059] Initial state: the self-resetting energy-dissipating support assembly 2 is arranged obliquely on the pullout member 3 of the shear wall to enha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com