Sewage treatment membrane with high leakage performance and preparation method thereof

A technology for sewage treatment and treatment membranes, which is applied in the field of sewage treatment membranes with high leakage and its preparation, can solve the problems of poor water permeability, membrane cracks, and low water passage rate, and achieve the goal of prolonging the service life and improving the degree of purification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

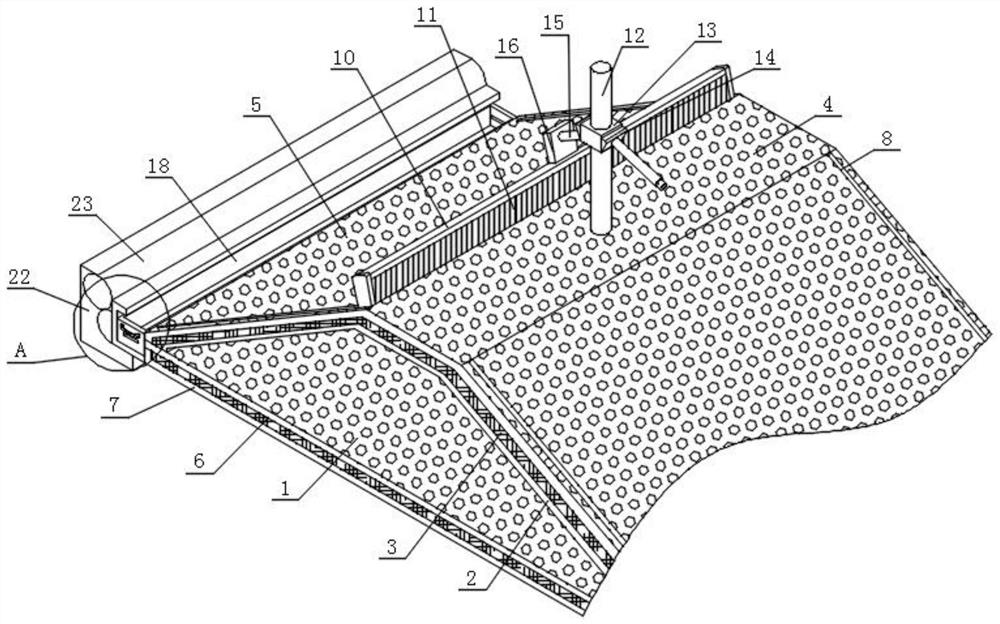

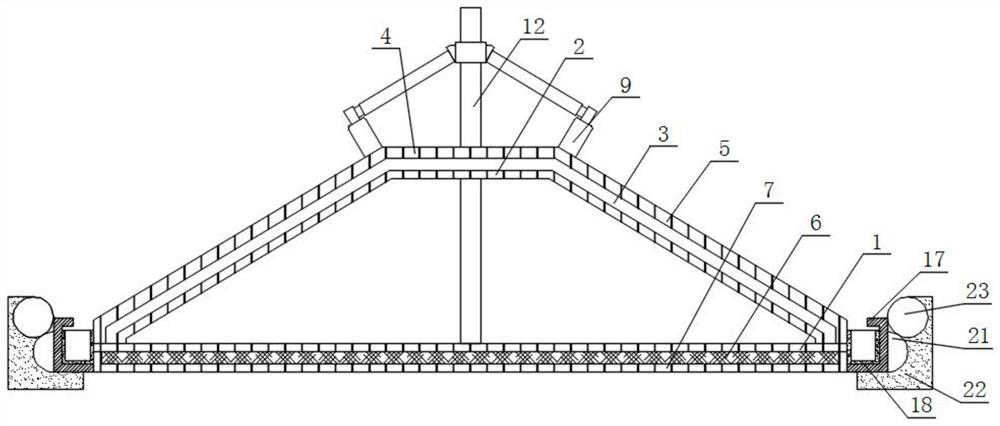

[0046] Such as figure 1 and figure 2 As shown, a kind of sewage treatment membrane with high leakage, including filter plate 1, filter trapezoidal plate 2, trapezoidal treatment membrane 3 and filter press plate 4, the top of filter plate 1 is equipped with filter trapezoidal plate 2;

[0047] A trapezoidal treatment membrane 3 is installed on the top of the filter trapezoidal plate 2, and a filter press plate 4 is installed on the top of the trapezoidal treatment membrane 3;

[0048] The outer walls of both sides of the filter platen 4 are equipped with filtering inclined plates 5, and the bottoms of the two groups of filtering inclined plates 5 are all attached to the outer surface of the trapezoidal treatment membrane 3, and the bottom of the filter plate 1 is equipped with a flat treatment membrane 6, and the flat treatment The bottom of the membrane 6 is equipped with a filter stay 7 , and the tops of both sides of the filter stay 7 are attached to the bottom of the fil...

Embodiment 2

[0051] Such as figure 1 , image 3 , Figure 4 and Figure 5 As shown, the tops of the two groups of filter inclined plates 5 are provided with two groups of fitting grooves 8 arranged front and back, and the inner walls of the four groups of fitting grooves 8 are equipped with movable plates 9, and the tops of the movable plates 9 extend out of the fitting In the inside of the groove 8, the backs of the two groups of movable plates 9 are equipped with connecting long plates 10, and the backs of the two groups of connecting long plates 10 are respectively attached to the fronts of the other two groups of movable plates 9, and the bottoms of the connecting long plates 10 are installed. There is a brush assembly 11, and the bottom of the brush assembly 11 is attached to the top of the filtering inclined plate 5.

[0052] Specifically, the setting of the fitting groove 8 can facilitate the fitting of the bottom of the movable plate 9, and then increase the connection between t...

Embodiment 3

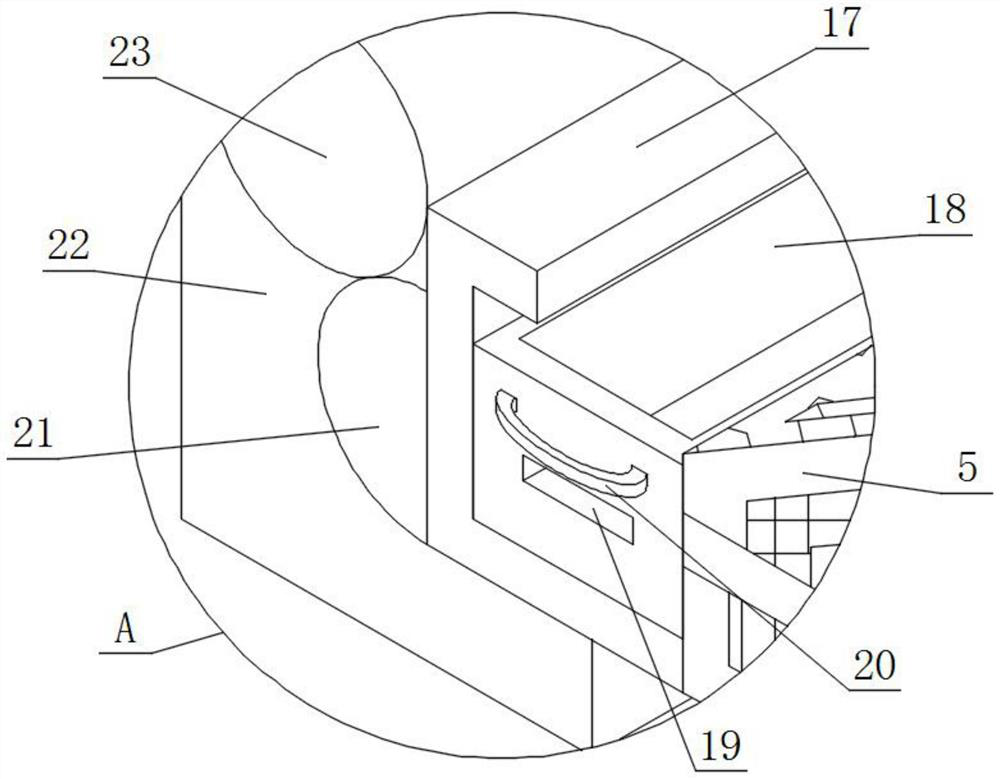

[0059] Such as figure 2 , image 3 and Figure 6 As shown, elastic hemispheres 21 are installed on the outer wall of the L-shaped flap 17 away from the filter support plate 7 .

[0060] The bottoms of two groups of L-shaped folding plates 17 are equipped with L-shaped storage board 22, and the inwall of the depression of L-shaped storage board 22 is equipped with elastic club 23, and the outer surface of elastic club 23 is attached to the outer surface of elastic hemisphere 21. combine.

[0061] Specifically, the sewage treatment membrane component is placed in a filter box with L-shaped storage plates 22 installed on both sides, and then the sewage treatment membrane component is applied with a driving force towards the location of the L-shaped storage plate 22, so that the elastic hemisphere 21 and the elastic ball The rod 23 is squeezed, and then shrinks its own thickness at the same time, and then the elastic hemisphere 21 can be fitted between the L-shaped storage pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com