Electronic ceramic tape casting raw material mixing equipment

A technology of tape casting and electronic ceramics, applied in mixers, mixers with rotating stirring devices, dissolving, etc., can solve the problems of uneven mixing, poor quality of electrical components, residues, etc., and achieve good mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

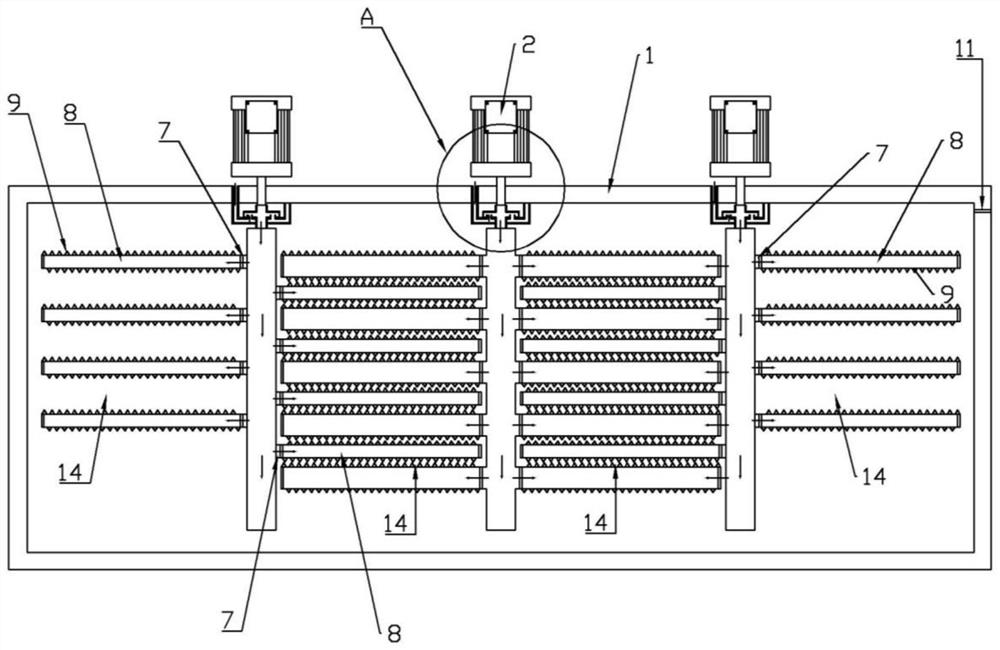

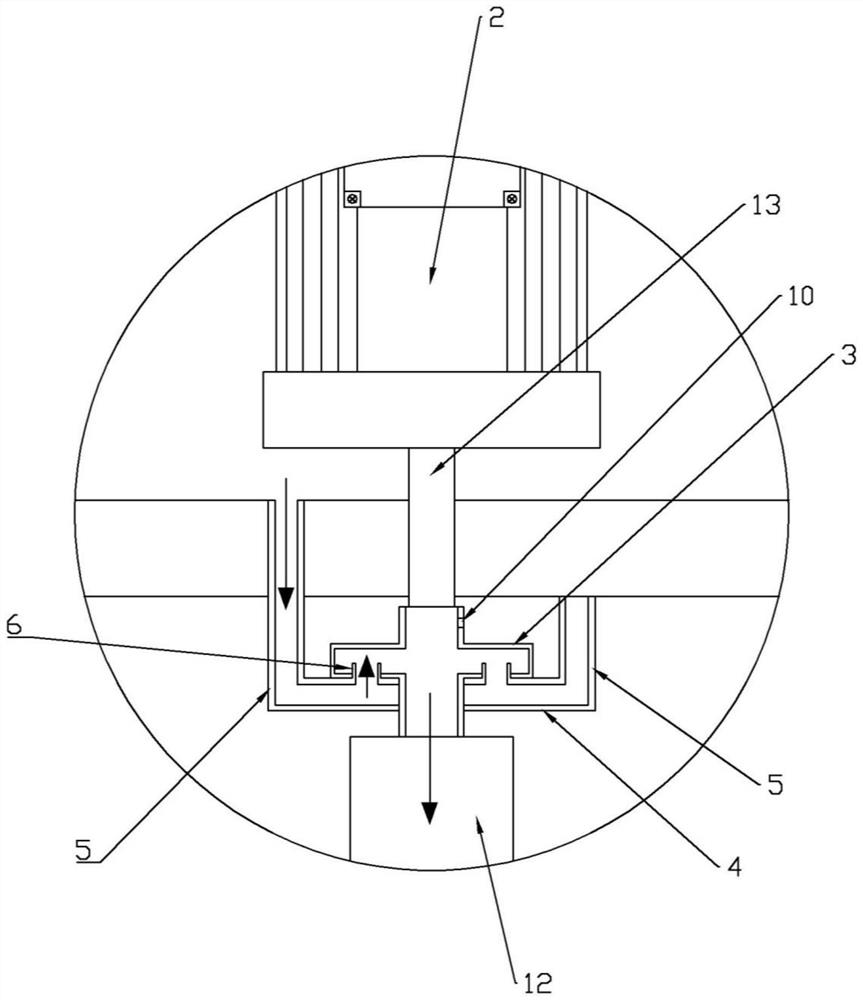

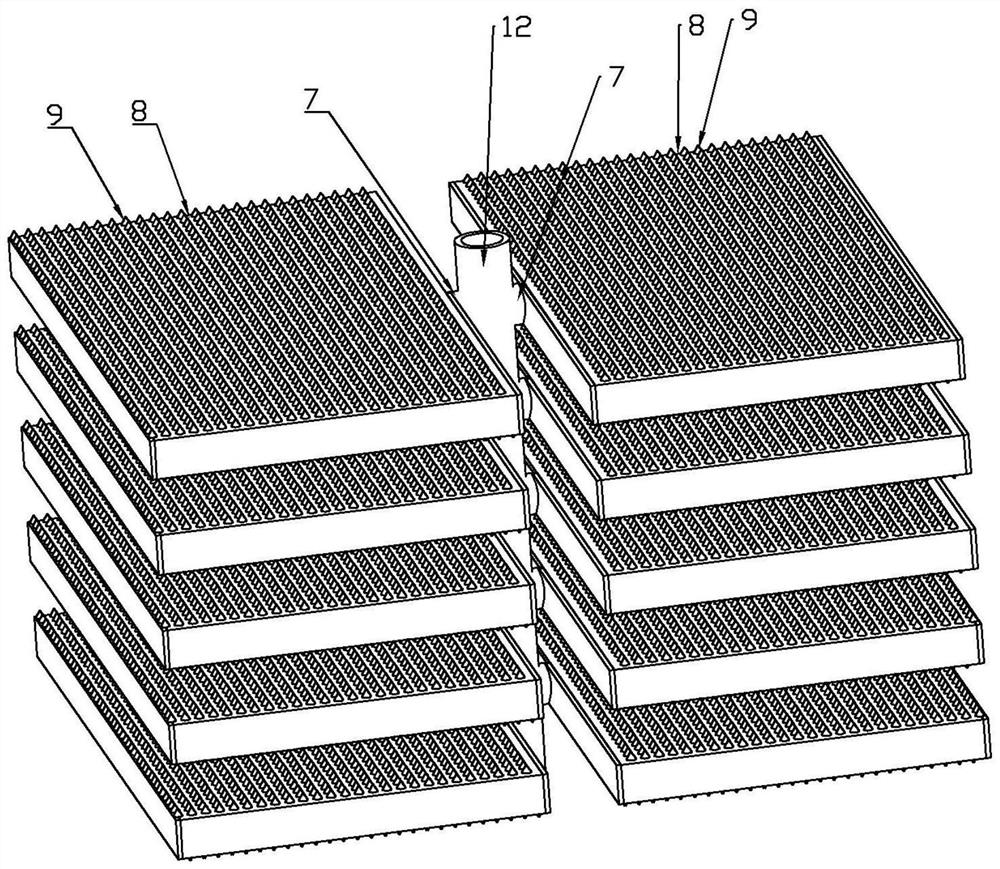

[0033] refer to Figure 1-7 , a material mixing device for tape casting electronic ceramics, comprising a mixing body 1, a driving motor 2, an air intake device, a communication device, and an integrated stirring and heating device.

[0034] The mixing body 1 is a hollow body, and three driving motors 2 are arranged on the top of the mixing body 1. The motor shaft 13 of the driving motor 2 is connected to the connecting device and the connecting device is located in the mixing body. Pipe 3, the lower ends of both sides of the "ten" shaped connecting pipe 3 are provided with annular air passages connected with the inside of the mixing body 1, and the air intake device is made of an air intake disc 4 attached to the bottom of the "ten" shaped connecting pipe 3 , communicate with the intake support tubes 5 located on both sides of the intake disc 4, the upper end of the intake disc 4 communicates with a guide tube 6 and the guide tube 6 extends into the annular air passage.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com