Computer case processing surface paint spraying equipment with paint recycling structure

A computer case and surface processing technology, which is applied to spray devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inconvenient recycling, inconvenient deodorization, inconvenient cleaning, etc., to avoid waste and improve the effect of adsorbing odors. The effect of reducing the air velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

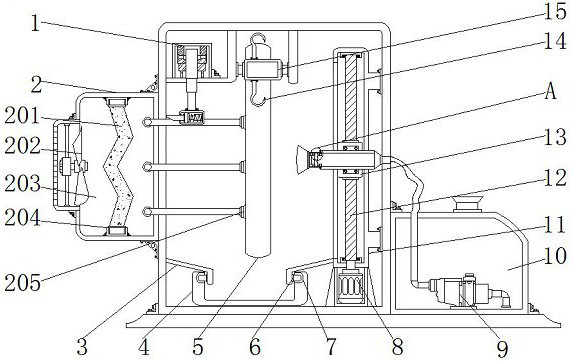

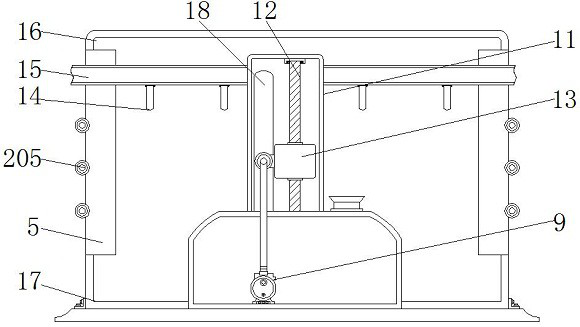

[0030] Example 1: See Figure 1-6 , a computer case processing surface painting equipment with a paint recovery structure, including a housing 16 and a bottom plate 17, and also includes a recovery mechanism 1 for easy recovery of paint, an adsorption mechanism 2 for avoiding odor pollution, and an installation structure for easy cleaning.

[0031] The top of base plate 17 is equipped with casing 16, and the two ends of casing 16 one side upper ends are all vertically provided with opening 5, and the middle position of casing 16 inside one side is vertically installed with fixed box 11, and fixed box 11 The bottom end of the housing 16 at the bottom is equipped with a drive motor 8, the model of which is YE2-132M1, and the output end of the drive motor 8 is vertically provided with a screw 12 extending to the inside of the fixed box 11 through a rotating shaft, and the screw The surface of the rod 12 is threaded with a rod block 13, and one end of the rod block 13 is installed...

Embodiment 2

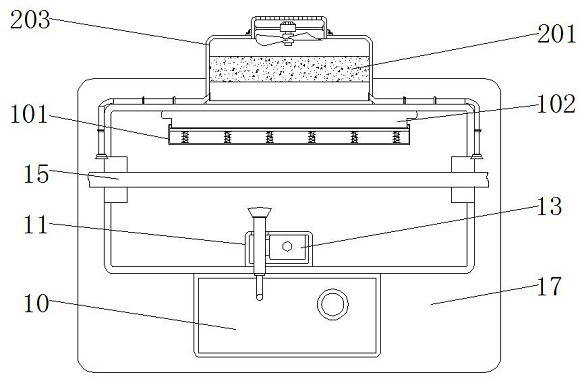

[0038] Embodiment 2: The recovery mechanism 1 comprises a recovery box 101, a scraper 102, a movable plate 103, a recovery spring 104 and a pneumatic telescopic rod 105, and the pneumatic telescopic rod 105 is installed on the inner top of the housing 16 on one side of the conveyor belt 15. The pneumatic telescopic rod The model of 105 can be XTL100, and the output end of the pneumatic telescopic rod 105 is equipped with a recovery box 101, and one side of the recovery box 101 is equipped with six recovery springs 104 at equal intervals, and the recovery box 101 on the side of the recovery spring 104 slides inside A movable plate 103 is connected, and a scraper 102 extending to the outside of the recovery box 101 is installed on one side of the movable plate 103 .

[0039] A slide block 6 is installed on one side of the bottom end of the swash plate 3 , and a chute 7 matched with the slide block 6 is provided at the upper ends of both sides of the collection tank 4 .

[0040] ...

Embodiment 3

[0041] Embodiment 3: adsorption mechanism 2 comprises activated carbon plate 201, negative pressure blower 202, adsorption box 203, slide groove 204 and suction head 205, and adsorption box 203 is installed in the middle position of housing 16 other sides, and adsorption box 203 Both the top and the bottom of one side of the interior are equipped with a sliding groove 204, and an activated carbon plate 201 is arranged inside the adsorption box 203 at one end of the sliding groove 204, and a negative pressure fan 202 is installed at the middle position of the side of the adsorption box 203 away from the housing 16. , the model of the negative pressure fan 202 can be HTF-I-3, three suction heads 205 are installed at equal intervals on both sides of the housing 16 on the side of the opening 5, and one side of the suction head 205 passes through the conduit and the adsorption box 203 Both ends are connected.

[0042] The shape of the activated carbon plate 201 is a side W shape, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com