Grinding brush special for quartzite and manufacturing process of grinding brush

A manufacturing process and technology for quartz stone, applied in the field of a special grinding brush for quartz stone and its manufacturing process, can solve the problems of no antique effect and low definition, and achieve the effects of good antique effect, high definition and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

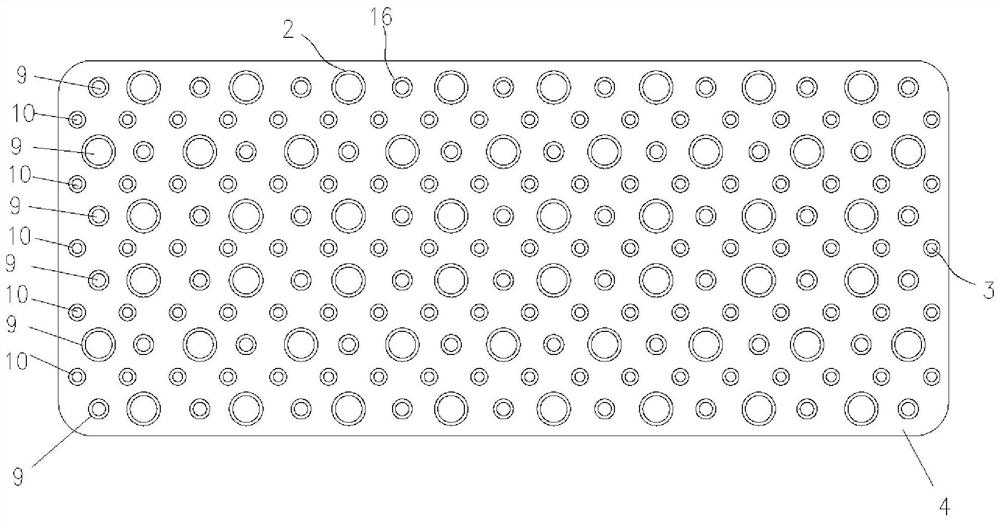

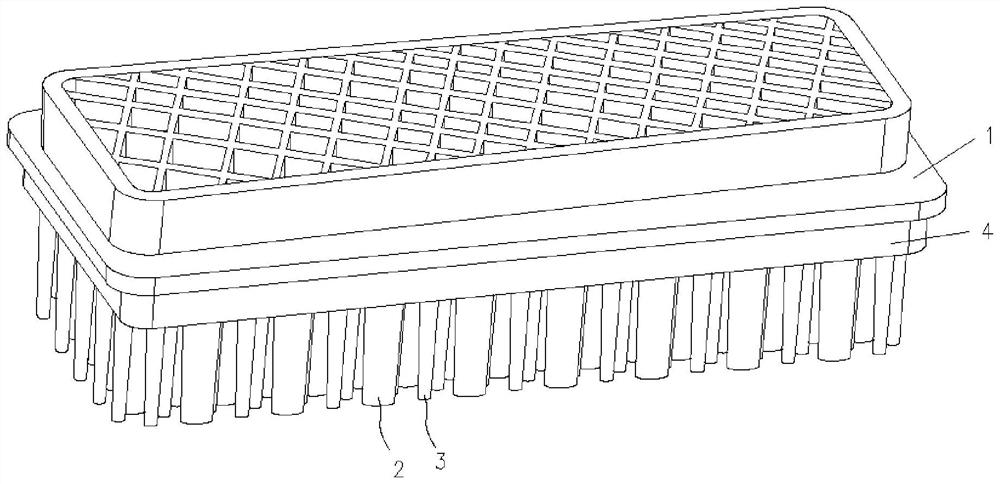

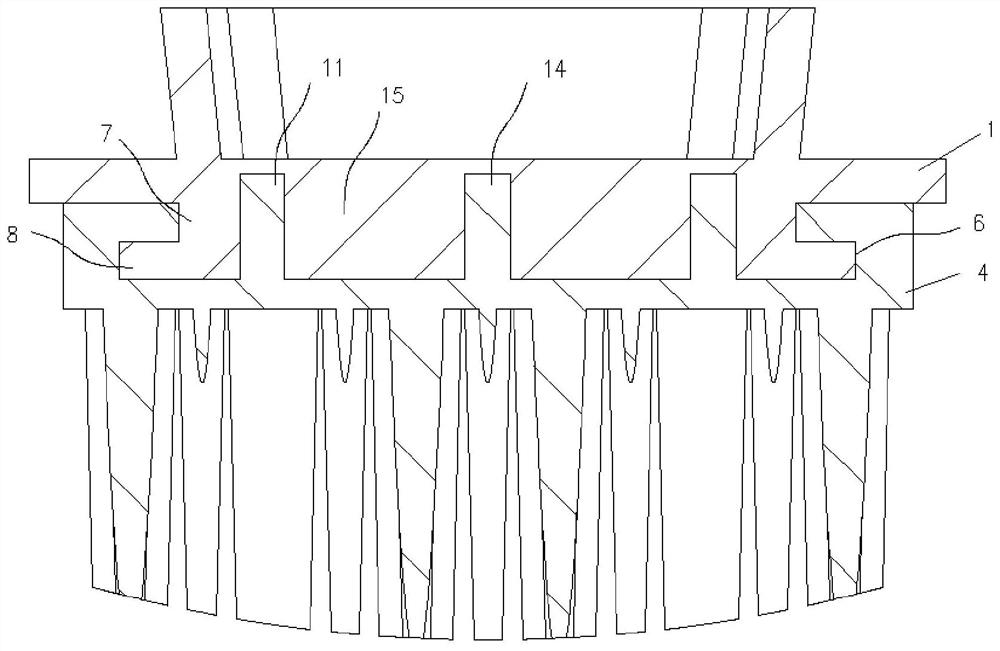

[0058] Embodiment one, such as figure 1 The first bristle group 9 includes a plurality of coarse bristles 2 and a plurality of medium bristles 16, and the plurality of coarse bristles 2 and the plurality of medium bristles 16 are distributed alternately. Correspondingly, the second bristle group 10 includes a plurality of thin bristles 3 . The diameter of the medium-shaped bristles 16 is smaller than the diameter of the thick-shaped bristles 2 and the diameter of the medium-shaped bristles 16 is larger than the diameter of the thin-shaped bristles 3 .

Embodiment 2

[0059] Embodiment two, such as Figure 8 The first bristle group 9 includes a plurality of thick bristles 2 and a plurality of thin brushes 3 , and correspondingly, the second bristle group 10 includes a plurality of thin bristles 3 .

[0060] Specifically, the diameter of the thick bristles 2 is 3.5 to 4.5 mm, preferably 3.5, 4 and 4.5 mm; the diameter of the medium bristles 16 is 1.5 to 2.5 mm, preferably 1.5, 2 and 2.5 mm; The diameter is 1-2 mm, preferably 1, 1.5 and 2 mm. In order to delay the service life of the bristles and reduce the impact of the bristles on the base 1, the diameter of the bristles decreases from the diameter near the base 1 to the diameter away from the end of the base 1. The diameter of the bristles is the diameter of the bristles away from the base 1 end. Specifically, when the diameter of the end of the thick bristle 2 away from the base 1 is 4 mm, the diameter of the end of the thick bristle 2 near the base 1 is 5 mm; The diameter of the end of...

Embodiment 3

[0107]A kind of manufacturing process of special grinding brush for quartz stone, comprising above-mentioned a kind of special grinding brush for quartz stone, by weight, including the following components:

[0109] Diamond: 25%;

[0110] Aluminum oxide: 8%;

[0111] Glass fiber reinforced nylon compound: 20%;

[0112] Nylon: 30%;

[0113] Additives: 2%, of which PA additives: 1.5%, zinc dialkyl dithiophosphate: 0.5%, silane coupling agent: 0.5%;

[0114] Styrene-butadiene thermoplastic elastomer: 25%;

[0115] The manufacturing process includes the following steps:

[0116] Step 1: Carry out dehydration treatment to nylon, auxiliary agent and toughening agent respectively;

[0117] Step 2: Weigh the nylon, auxiliary agent and toughening agent in step 1 according to the formula, put the nylon, auxiliary agent and toughening agent into the reaction kettle for mixing and heating, heat the temperature to 260°C, stop heating and keeping warm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com