Dyeing and finishing method of dacron high-shrunk filament monolayer concave-convex bed product fabric

A high-shrinkage silk and fabric technology, applied in textiles and papermaking, fabric surface trimming, improved hand-feeling fibers, etc., can solve problems such as insufficient research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

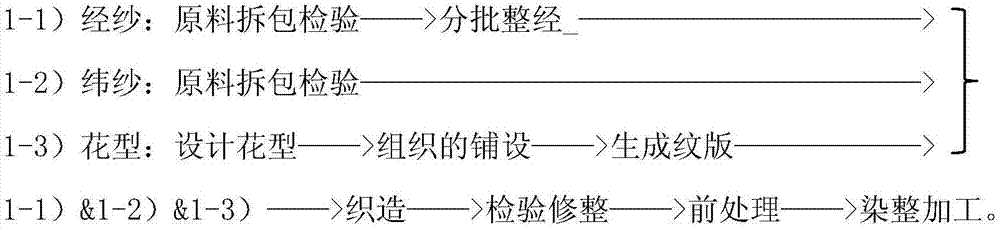

Method used

Image

Examples

Embodiment Construction

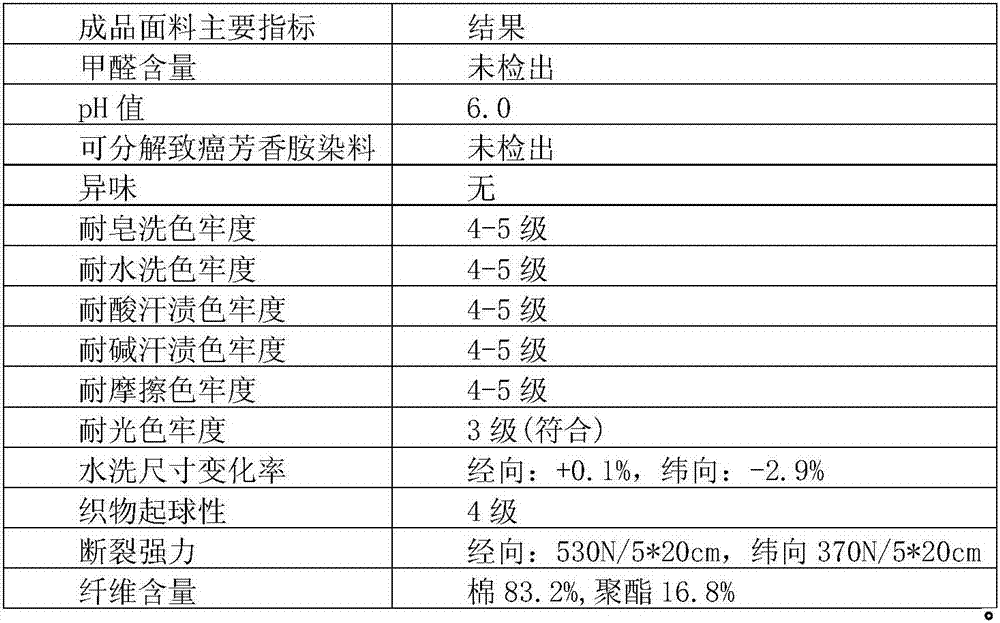

[0021] In this example, the initial trial production of 200 meters, the fabric specification is JCF9.7TEX×(C9.7TEX+FDY150D / 72F)2:1681×283 pieces / 10CM, the width is 300CM, and the weight is 110G / M 2 .

[0022] The technical indicators to be achieved by the single-layer concave-convex bedding fabric prepared by the method are as follows: 1. The layers of the pattern are clear, and the fabric presents a concave-convex effect. 2. The internal indicators and appearance quality of fabric quality meet the requirements of first-class products in relevant standards.

[0023] Technical problems solved in trial production

[0024] (1) The product selects suitable FDY high-shrinkage yarn from the source, which not only realizes the low weight of the fabric, but also ensures the embossed and embossed style of the fabric. FDY150D / 72F high-shrinkage yarn is used in the weft direction, and the phenomenon of broken yarn should be prevented during weaving.

[0025] (2) The raised part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com