Vacuum metallizing metallic paper with embossing effect and production method thereof

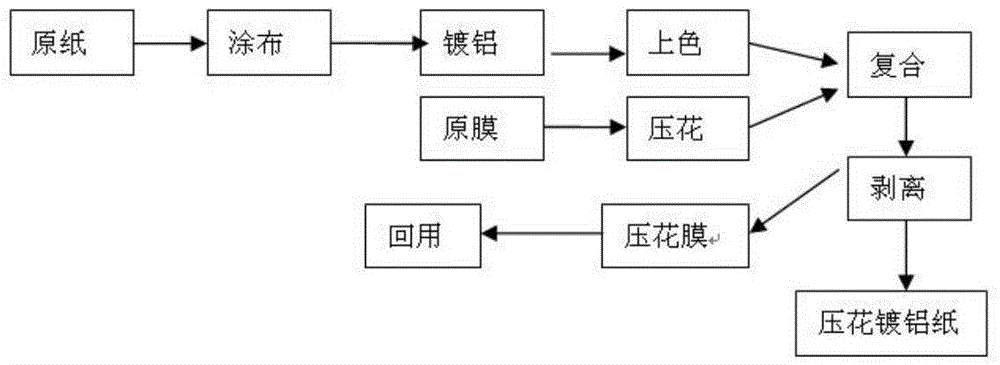

A technology of vacuum spraying and metal spraying, applied in the direction of patterned paper, special paper, paper, etc., can solve the problems of weakening the moisture-proof function of packaging materials, characteristic odor, inability to form well, increasing paper breakage rate, etc., to achieve good Layered and three-dimensional effects, increased production efficiency, realistic embossing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

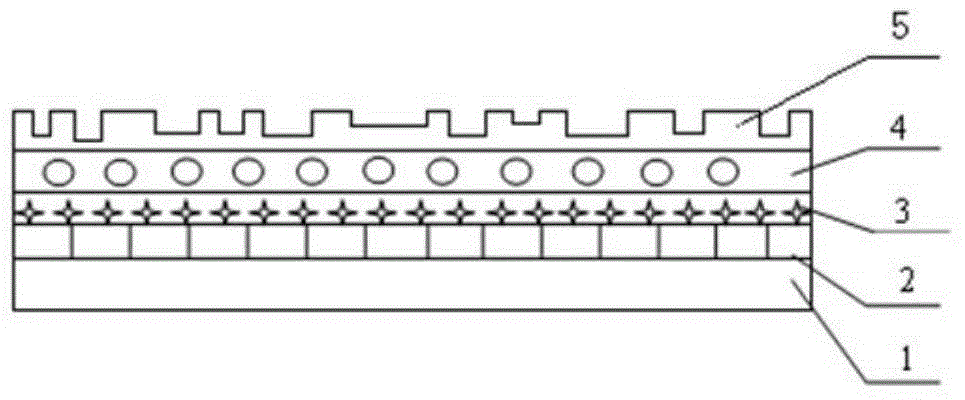

[0033] Metallized aluminum paper products with golden embossing effect, refer to the attached figure 1 .

[0034] (1) Embossing: Use an embossing roller with a pre-designed pattern to emboss on one side of the PET film or OPP film on the embossing machine, and press the pre-designed pattern and pattern effect on the working surface of the film , to prepare embossed films with exquisite patterns.

[0035] (2) Coating: Apply a layer of water-based resin coating evenly on the base paper by using mesh roller feeding or multi-roller extrusion feeding, and control the quality of the coating resin at 1.2±5.0g / m 2 , the coating resin is cured under certain conditions, and the cured resin forms a smooth pre-coating resin layer on the surface of the paper to prepare pre-coated paper.

[0036] (3) Aluminizing: Put the pre-coated paper in the vacuum aluminum-plating equipment, evacuate to 5E-4mbar, heat the aluminum wire, make it volatilize quickly and become metal aluminum vapor, and s...

Embodiment 2

[0043] For metal sprayed aluminum primary color paper products with embossing effects, still refer to the attached figure 1 , the product has less coloring layer than Example 1, and there is no coloring process in the corresponding production process.

[0044] (1) Embossing: Use an embossing roller with a pre-designed pattern to emboss on one side of the PET film or OPP film on the embossing machine, and press the pre-designed pattern and pattern effect on the working surface of the film , to prepare embossed films with exquisite patterns.

[0045] (2) Coating: Apply a layer of water-based resin coating evenly on the base paper by using mesh roller feeding or multi-roller extrusion feeding, and control the quality of the coating resin at 1.2±2.5g / m 2 , the coating resin is cured under certain conditions, and the cured resin forms a smooth pre-coating resin layer on the surface of the paper to prepare pre-coated paper.

[0046] (3) Aluminizing: Put the pre-coated paper in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com