Deepwater grouting anchor and construction method

A grouting, deep water technology, applied in anchor points, anchoring arrangements, infrastructure engineering and other directions, can solve the problems of unstable bearing capacity, difficult to control the shape of grouting anchor body, etc., to ensure stability and reduce the risk of debonding , safe and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

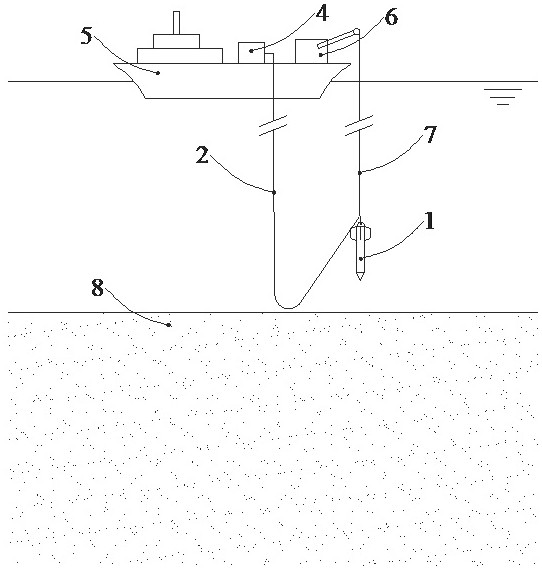

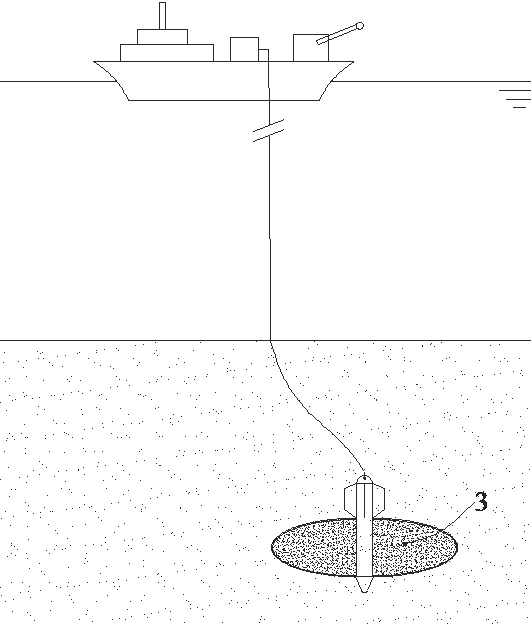

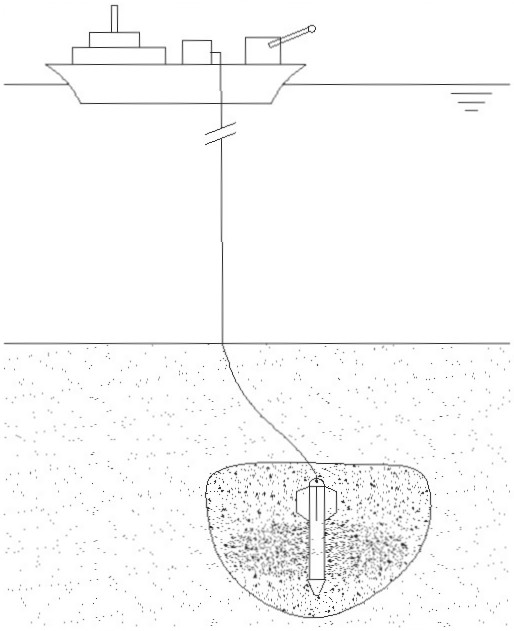

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0031] like Figure 1-5 As shown, a deep-water grouting anchor includes an anchor body 1, an anchor cable and a grouting pipe 2, and an elastic-plastic restraint sleeve 14;

[0032] The upper end of the anchor body is connected with the anchor cable, the upper end of the anchor body is provided with a grout inlet 111 for connecting with the grouting pipe, and several grout outlets 113 are arranged on the anchor body, and the grout outlet and the grout inlet are arranged in the anchor body The pulp passing channel 112 is connected;

[0033] The elastic-plastic constraining sleeve includes an elastic-plastic constraining membrane and a terminal fixing assembly. The elastic-plastic constraining membrane is cylindrical, wrapped around the outer periphery of the anchor body and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com