Inertia stabilization system used for lifting hook of offshore crane

A crane and inertial technology, applied in the field of inertial anti-rolling systems, can solve problems such as affecting the safety of operators and construction facilities, affecting the efficiency of offshore operations and engineering progress, and increasing the cost of offshore operations, so as to reduce the swaying characteristics of the hook and shorten the marine life. The construction period and the effect of improving the efficiency of offshore operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

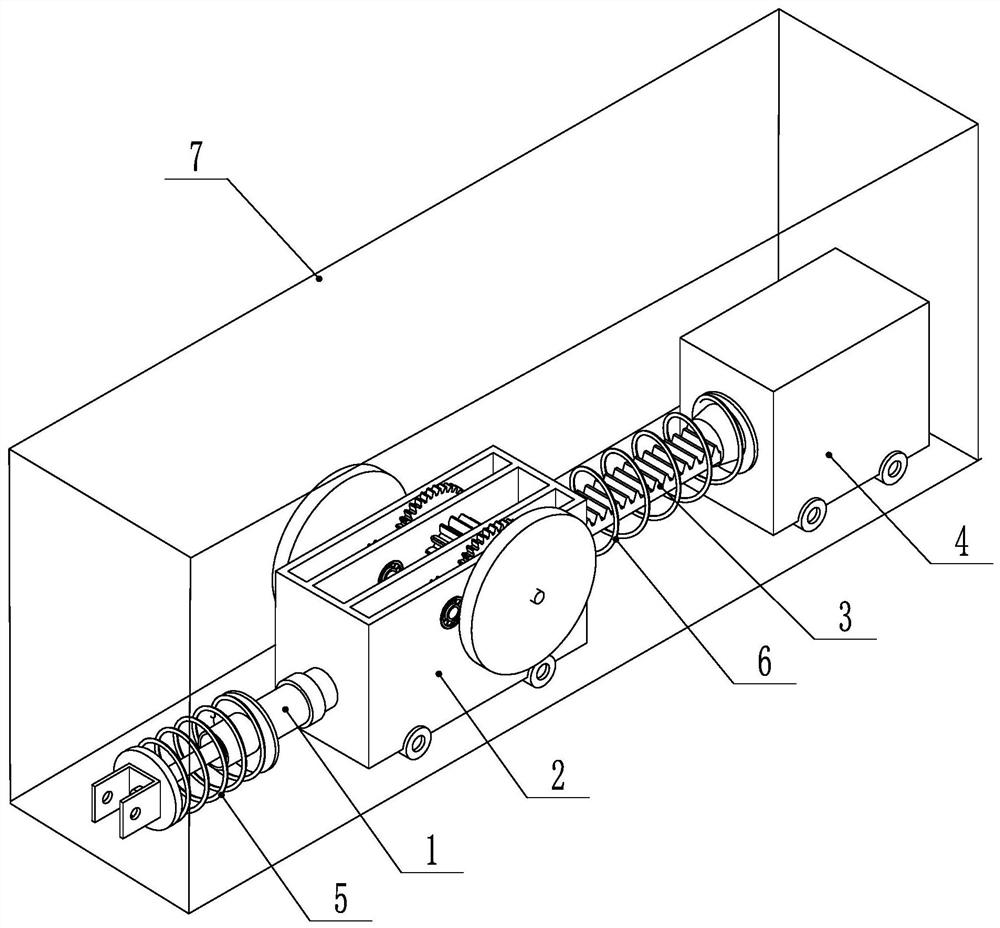

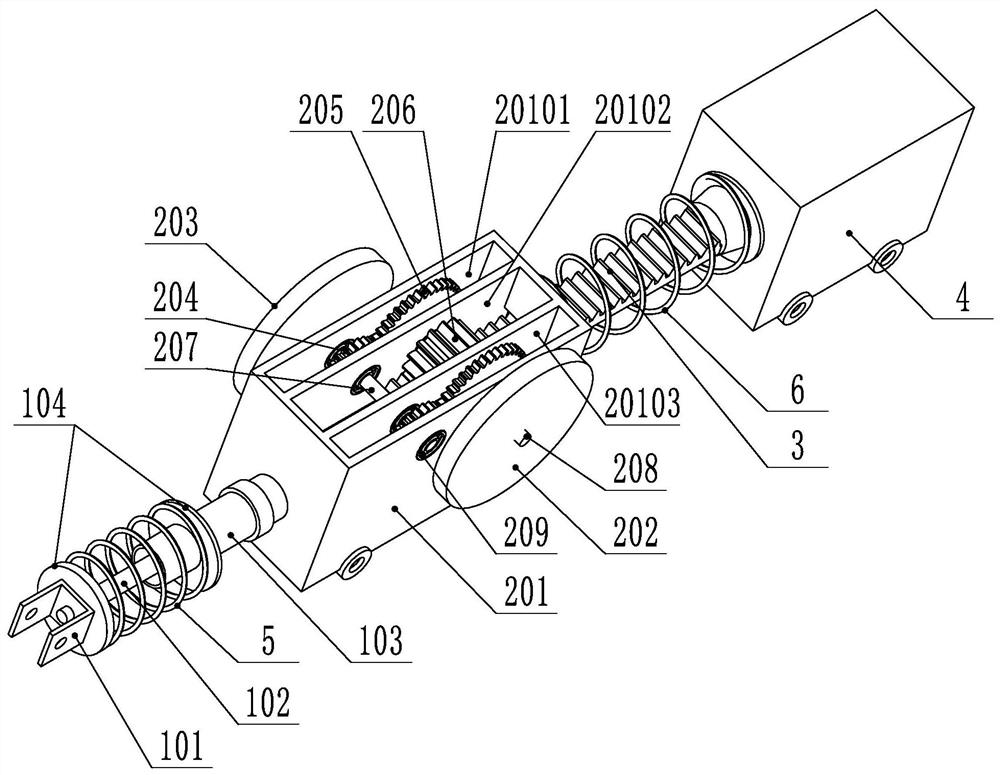

[0020] Such as figure 1 , 2 As shown, an inertial anti-rolling system for a hook of an offshore crane includes a housing 7 and a main body of the anti-swaying system disposed in the housing 7. The main body of the anti-swaying system includes a damping device 1, a spring, and a slidable inertial transmission Device 2, transmission connection rack 3 and sliding counterweight 4, the spring includes a first spring 5 and a second spring 6, the damping device 1 includes a tail fixed pair 101 and a damper 103, the tail fixed pair 101 passes through a damping sliding rod 102 Slidingly connected with the damper 103, the first spring 5 is set on the damping sliding rod 102, and the two ends of the first spring 5 are elastically attached to the tail fixed pair 101 and the stop plate 104 on the damper 103 respectively, and the damper 103 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com