Process for controlling double-frequency quenching deformation of slender H13 straightening roll

A technology of straightening rollers and frequency quenching, which is applied in the field of dual-frequency quenching deformation control of slender H13 straightening rollers, which can solve the problems of poor jumping deformation of straightening rollers, inability to straighten, large deformation, etc., and reduce quenching stress , Reduce energy consumption, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The product size of the H13 straightening roller used in this embodiment is: φ315X4450 / 5506. The hardness of the roll body is required to be HRC54-56, and the layer depth is 12-14mm. The main components of the product are shown in Table 1, and the basic parameters of the dual-frequency quenching transformer used are shown in Table 2;

[0025] Table 1H13 Main components of straightening rollers

[0026] C Si mn Cr Mo V 0.38 1.10 0.45 5.20 1.55 1.30

[0027] Table 2 Basic parameters of dual-frequency quenching transformer

[0028]

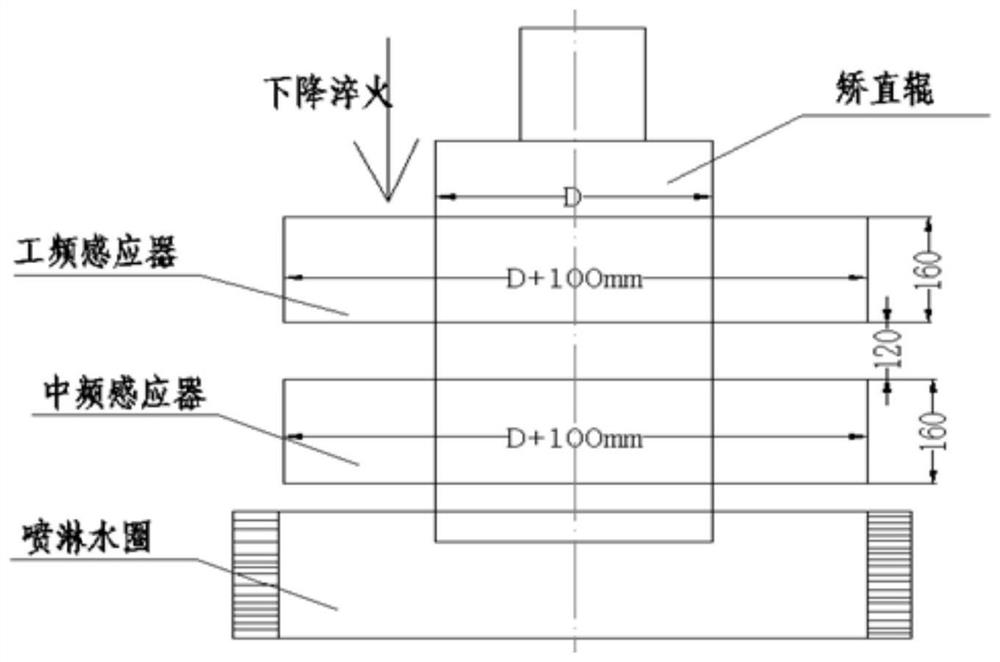

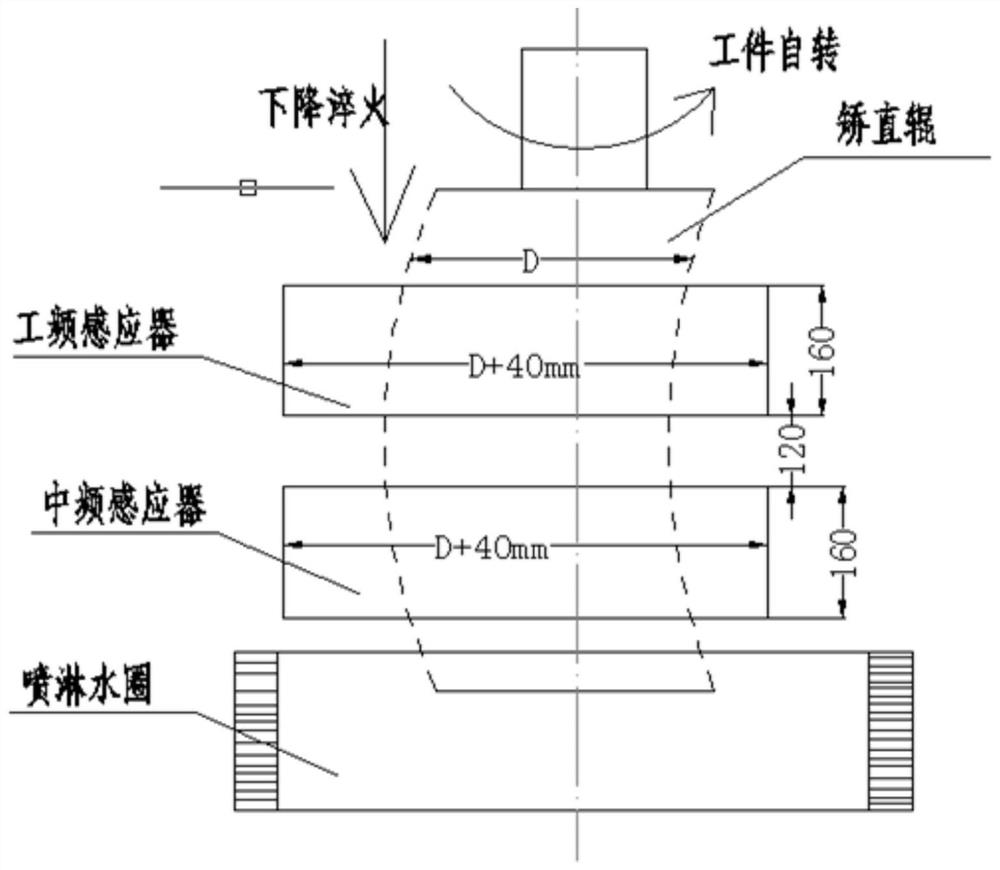

[0029] Adopt technology of the present invention to operate, as figure 1 As shown, the specific steps are as follows:

[0030] (1) Stress relief before quenching

[0031] Place the H13 straightening roller in a trolley-type resistance furnace, raise the temperature to 650°C at a rate of 80°C / h and keep it warm for 5-6h, and then cool the furnace to about 300°C for straightening after power failure, until t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com