An automatic liquid level compensation method

A technology of automatic compensation and liquid level, applied in chemical instruments and methods, self-melting liquid pulling method, single crystal growth, etc., can solve the problems of inaccurate control accuracy and inability to form a whole rod, so as to improve the yield and effectively Favorable effect on crystal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A liquid level automatic compensation method, comprising the following steps:

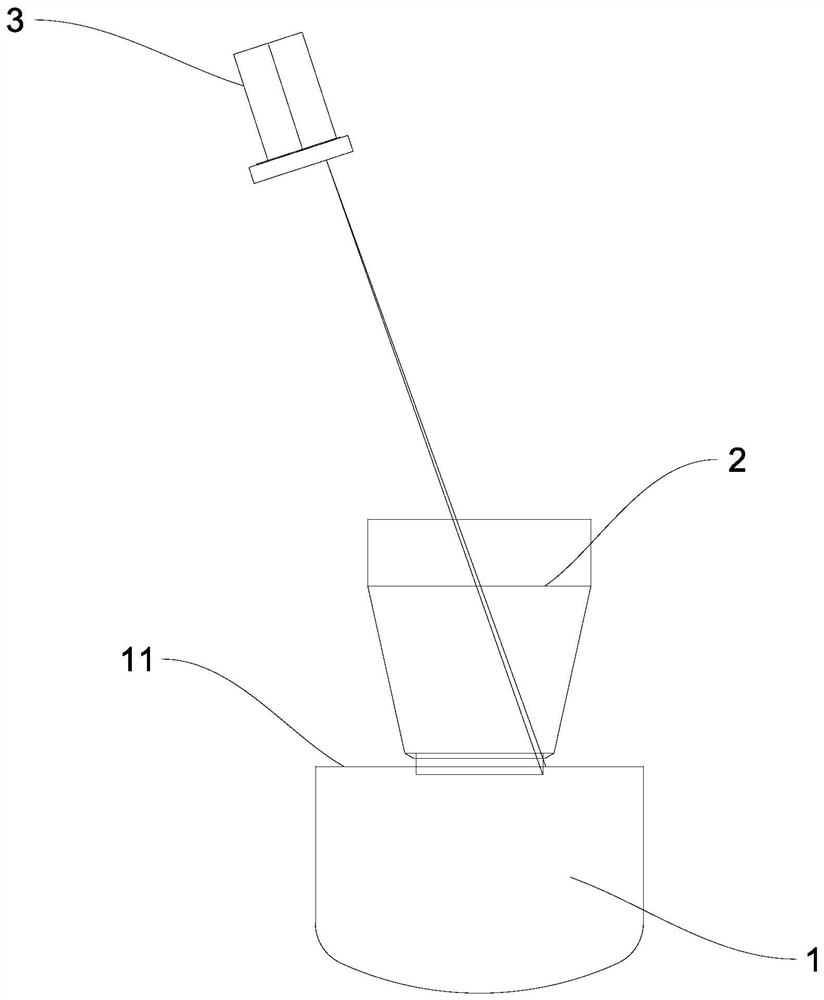

[0030] S1: The crucible 1 contains silicon liquid, the crucible 1 is provided with a water-cooled heat screen 2 above the silicon liquid level 11, an imaging device 3 is provided above the water-cooled heat screen 2, and a lift is provided below the crucible 1 device 5;

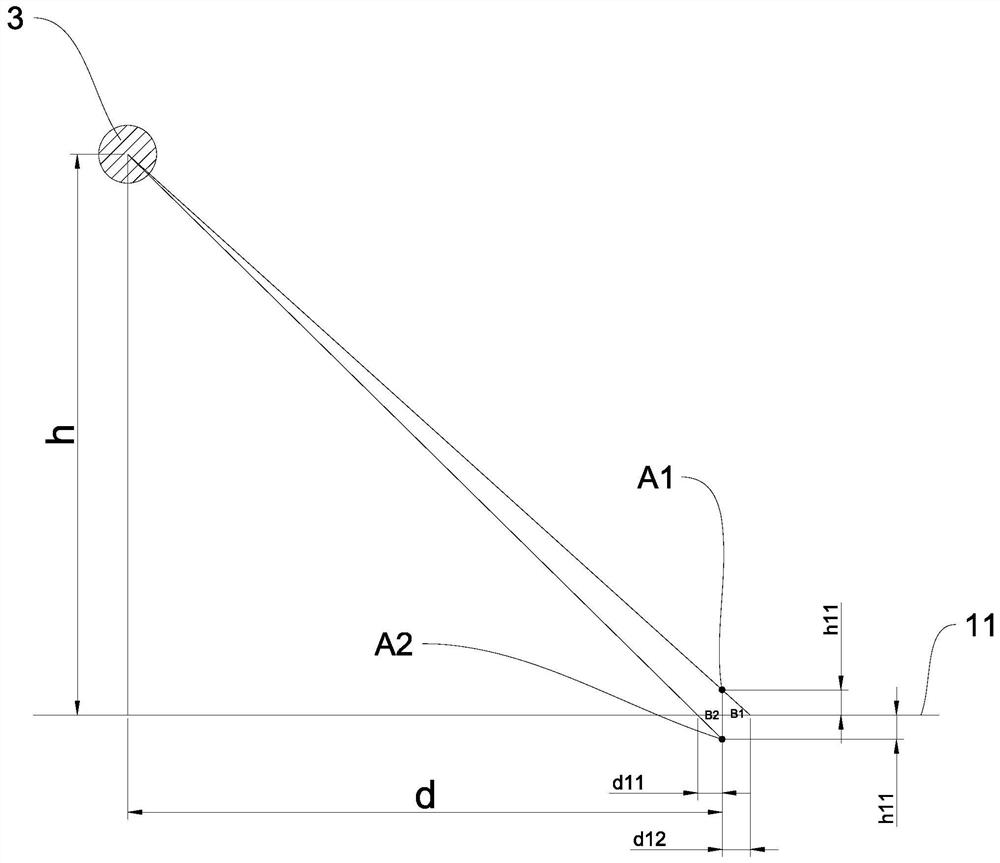

[0031] S2: The imaging device 3 emits light through the screen of the water-cooled heat screen 2 to form an observation point A1 on the silicon liquid level 11, and the observation point A1 forms an observation line-B1 with a length of d12 on the silicon liquid level 11 At the same time, the screen mouth of the water-cooled and hot screen 2 forms a projection point A2 under the mirror projection of the silicon liquid level 11, and the projection point A2 forms an observation line B2 with a length of d11 on the silicon liquid level 11. The imaging device 3 is far from the silicon liquid level 11. The distance between the li...

Embodiment 2

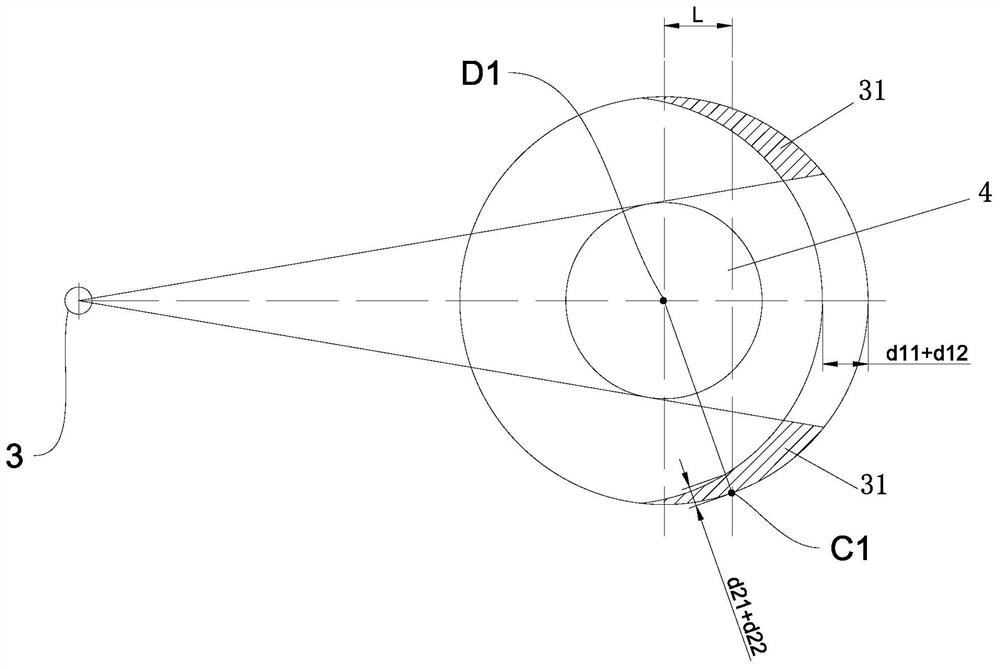

[0040] The screen mouth of the water-cooled and hot screen 2 is in the shape of a crescent when the imaging device 3 is imaging. In the actual production process, the raw materials are melted and then crystallized to form a crystal rod. Therefore, the visible area of the actual imaging device 3 is as follows: image 3 shown. In the actual imaging area, the measurement position of d11+d12 cannot be directly selected for measurement due to the position of the ingot 4. Therefore, in the actual use process, in the middle area of the imaging visible area 31, take an observation point three C1, the observation point The horizontal distance between C1 and the imaging center is L, and the distance d21+d22 that needs to be measured is obtained by connecting the line with the imaging center.

[0041] In the step S2, the light emitted by the imaging device 3 is imaged as the imaging visible area 31 through the water-cooling and hot screen 2, the center of the imaging visible area 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com