Trenching assembly of chain type trencher

A trenching machine and chain technology, applied in the field of trenching components, can solve the problems of not being able to dig grooves specially, increase product cost, and wear blades too fast, and achieve the effects of improving work efficiency, efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

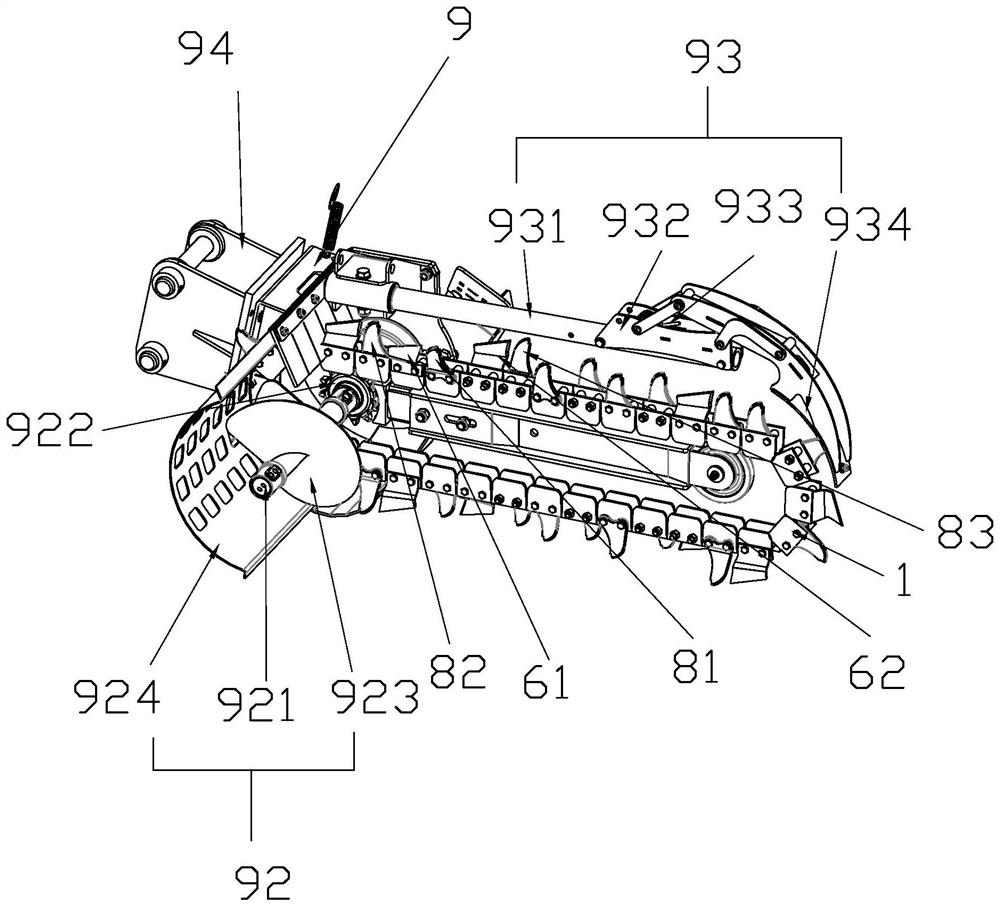

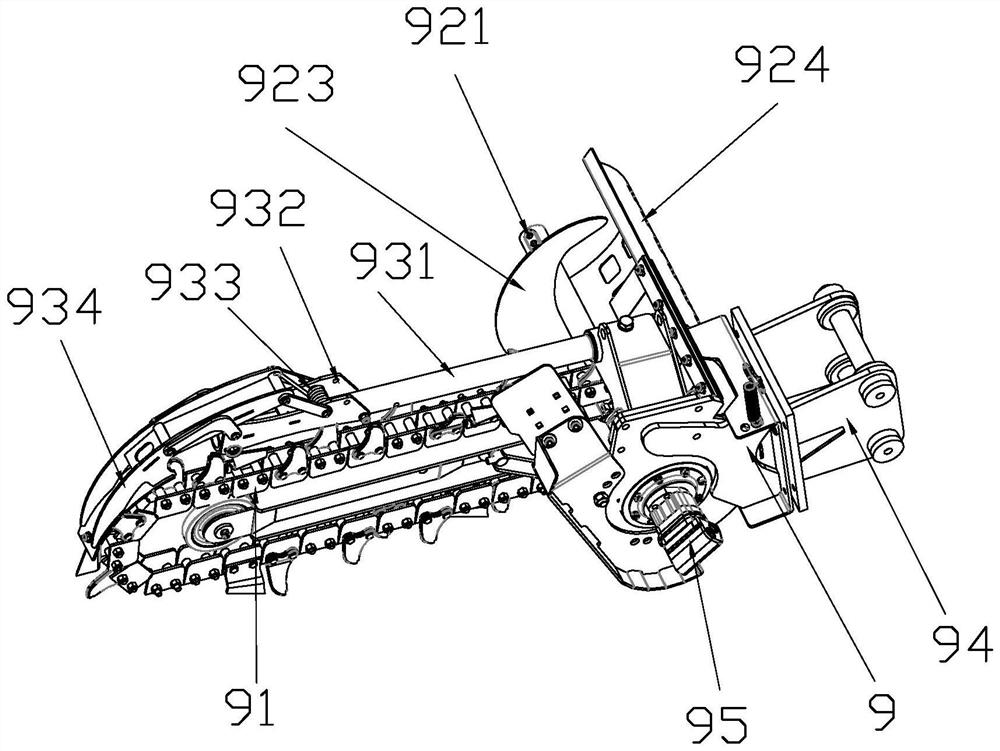

[0039] Such as Figure 1-Figure 14As shown, a ditching assembly of a chain trencher includes a frame 9, a cutter chain 91, a spiral soil removal device 92 and a soil clearing scraper device 93, and one end of the frame 9 is provided for connecting with the ditcher. Connected mounting base 94, the other end is provided with the driving guide wheel device that drives cutter chain and spiral earth moving device to rotate, and described driving guide wheel device comprises the drive motor 95 that is arranged on frame 9 one side, the output end of drive motor 95 An output shaft 921 is provided to drive the screw soil removal device 92 to work. The output shaft 921 is provided with a sprocket 922, and drives the cutter chain 91 to rotate through a chain transmission. Above, and connected with the frame 9 through the big arm 931, the cutter chain 91 is vertically arranged with the screw soil removal device 92, and the cutter chain 91 is sequentially combined by several groups of circ...

Embodiment 2

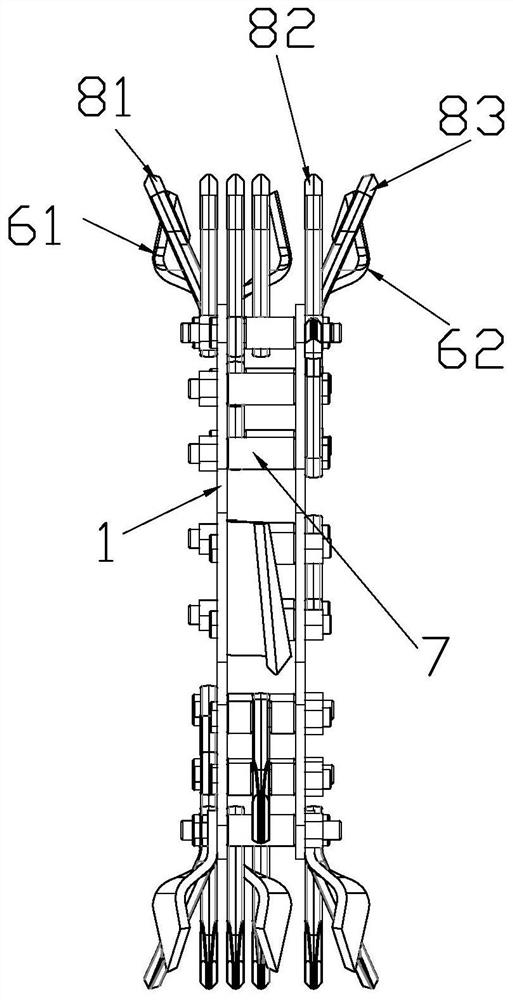

[0042] Such as Figure 10 , Figure 11 , Figure 12 , Figure 14 As shown, when trenching on soft ground, the trenching tooth group includes a left soil drilling cup tooth 61 and a right soil drilling cup tooth 62, and the left soil drilling cup tooth 61 is arranged on the left side of the outer chain plate 2. On the bolt 3 and one end extends to the outside of the outer link plate 2 to form a left arc plate 611, and the right drilling cup tooth 62 is arranged on the bolt 3 on the right side of the outer link plate 2 and one end extends to the outside of the outer link plate 2 to form a right arc plate 621, the bolt 3 between the two outer chain plates 2 can be loaded with a left soil drilling cup tooth 61 or a right drilling soil cup tooth 62, and the left soil drilling cup tooth 61 and the right drilling soil cup tooth 62 are respectively along the chain The length direction is staggered, and one end of the bolt 3 corresponding to the left drilling cup tooth 61 or the rig...

Embodiment 3

[0046] Such as Figure 5-Figure 9 , Figure 13 As shown, when trenching on hard or frozen ground, the set of trenching teeth includes a left trenching tooth 81, a middle trenching tooth 82 and a right trenching tooth 83, and the left trenching tooth 81 is set outside On the bolt 3 on the left side of the chain plate 2 and one end extends to the outside of the outer chain plate 2 to form a left blade 811, the middle groove tooth sleeve 82 is arranged on the bolt 3 in the middle of the two outer chain plates 2 and one end is vertically outward Extend to form the middle knife wing 821, the right trenching tooth 83 is sleeved on the bolt 3 on the right side of the outer chain plate 2 and one end extends to the outside of the outer chain plate 2 to form a right knife wing 831, the left trenching tooth 81, the middle digging The groove teeth 82 and the right groove teeth 83 are respectively staggered along the length direction of the chain, and one end of the bolt 3 corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com