Nailed bamboo-wood plate type component

A technology of plate type and component, which is applied in the direction of building structure, construction, building materials, etc., can solve the problems such as the reduction of bending resistance of lap joints that cannot be overcome, achieve good application prospects, increase processing costs, and reduce material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

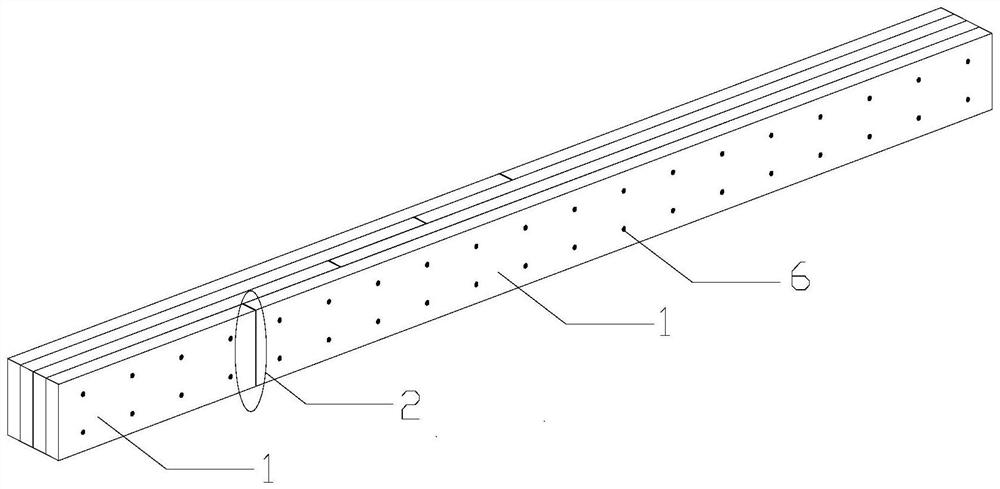

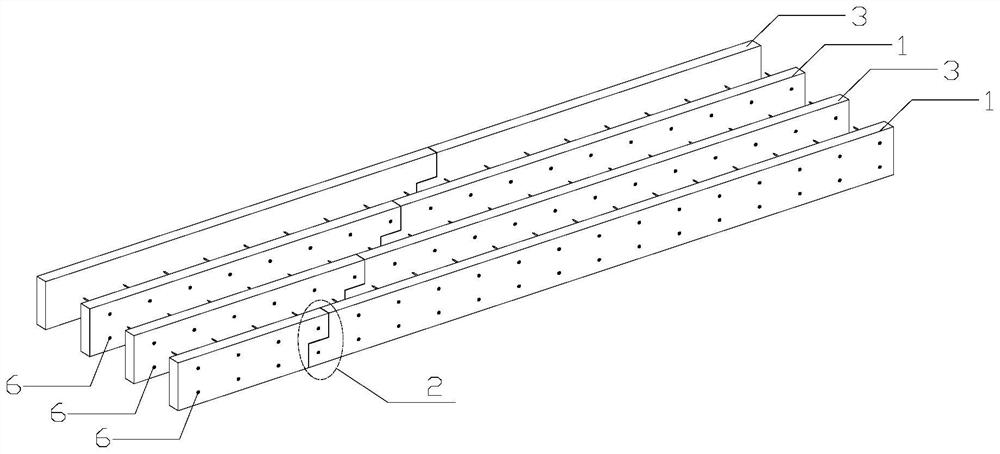

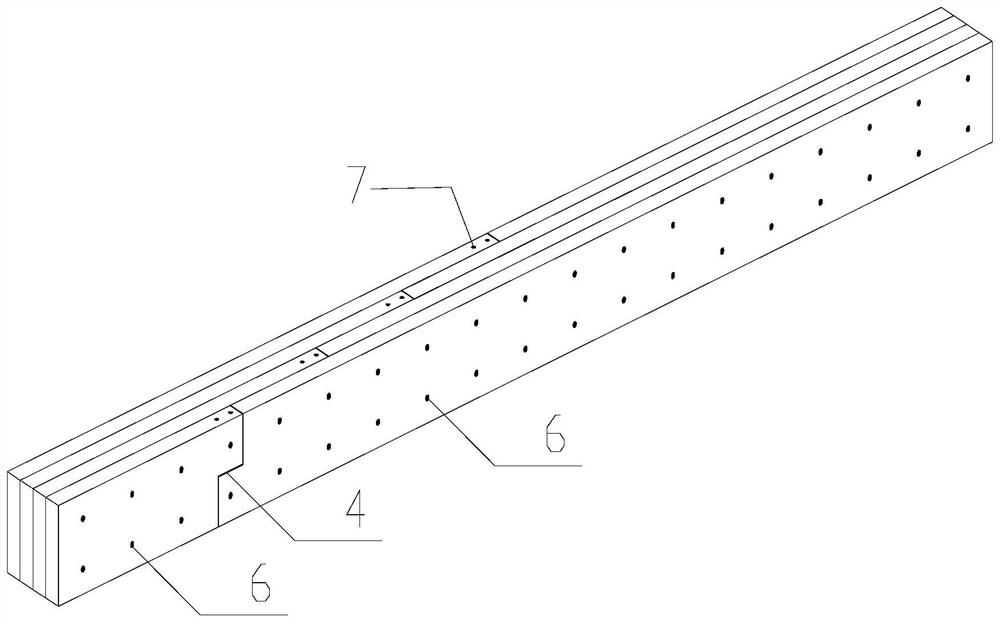

[0017] As shown in the accompanying drawings, the present invention is a nailed bamboo panel component, characterized in that: the engineering bamboo laminate (3) and the wooden laminate (1) with grooves (4) or bevels (5) at the end The wide surface is stacked layer by layer, and the connecting nails (6) driven in layer by layer are combined to form a panel member, and the reinforcement nails (7) are driven in from the top surface of the panel member to pair the engineering bamboo laminate (4) and wood laminate ( The lap joint (2) of 1) is reinforced; it is characterized in that: the quantity ratio of engineering bamboo laminates (3) and wooden laminates (1) can be adjusted as required.

[0018] During implementation, firstly, the end of the engineering bamboo laminate (3) is cut into a groove (4) or a bevel (5); then, the engineering bamboo laminate (3) and the wooden laminate (1) are cut along the wide surface Layer-by-layer stacking, the connecting nails (6) driven in layer...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap