Intelligent oil pipe lifting and pushing device for minor repair operation

A technology for pushing devices and oil pipes, which is applied in the direction of drilling pipes, casings, and drilling equipment. It can solve the problems that the oil pipe automatic discharge device occupies a large area, is not suitable for minor repair operations, and is not easy to install in place. It improves labor efficiency and is easy to install. Install in place, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

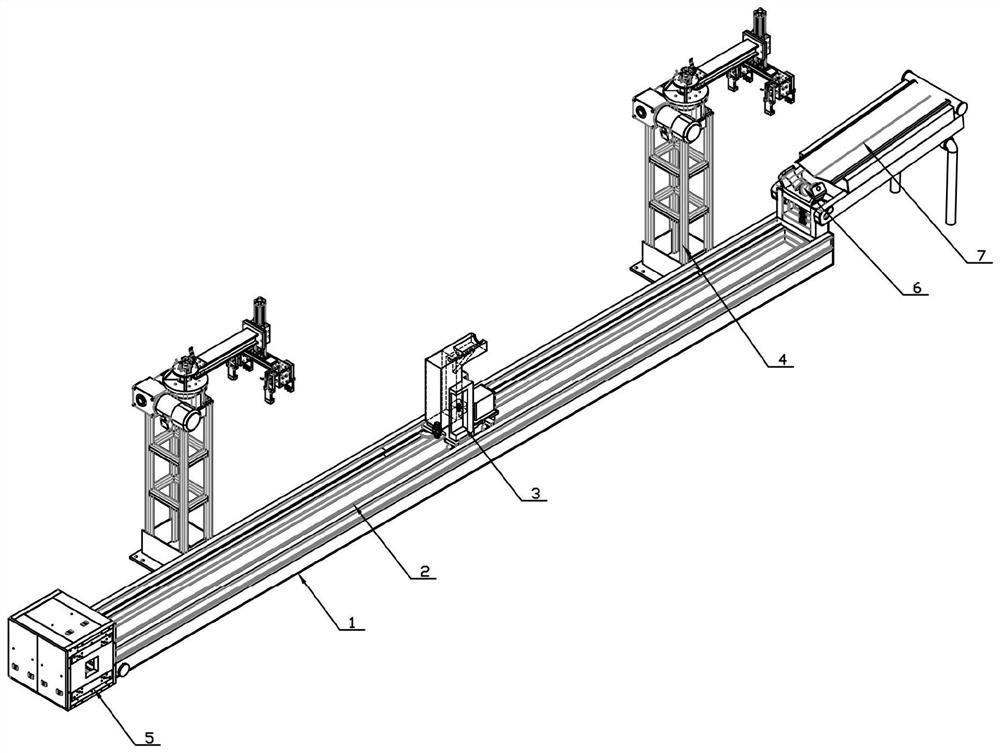

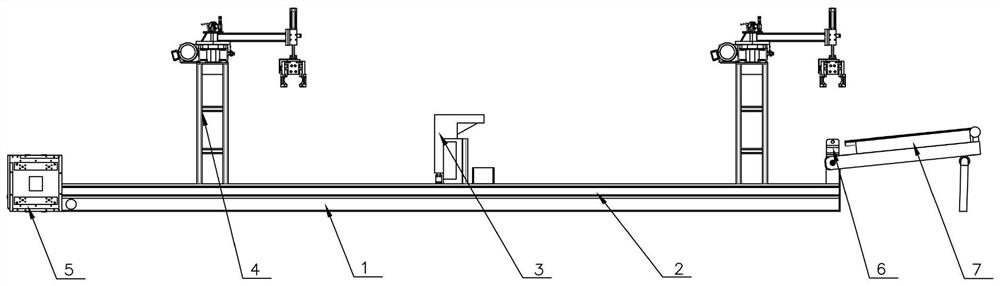

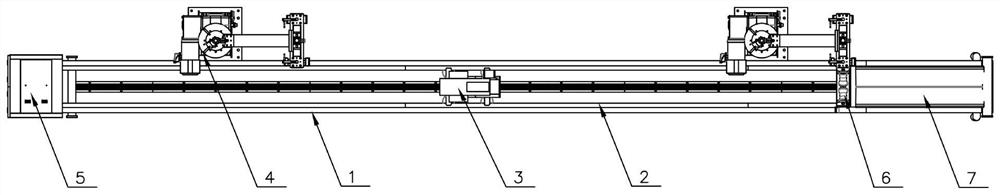

[0035] Such as Figure 1 to Figure 8 As shown, this embodiment provides an intelligent oil pipe lifting and pushing device for minor repair operations. The intelligent oil pipe lifting and pushing device includes a base 1, wherein, the base 1 is provided with a track 2, and the track 2 is provided with a lifting and pushing mechanism 3 that can slide along the track 2, and the same side of the base 1 is provided with at least two A grasping mechanism 4, the rear end of the base 1 is provided with a PLC controller 5, the front end of the base 1 is provided with a righting roller mechanism 6 perpendicular to the base 1, and the righting roller mechanism 6 is rotatably connected with a folding bracket 7, and the folding bracket 7 In the case of unfolding, it extends forward along the base 1, and the folding bracket 7 is arranged obliquely upwards from the back to the front. The folding bracket 7 can be placed on the top surface of the base 1 when it is folded, and the PLC control...

Embodiment 2

[0043] On the basis of Embodiment 1, this embodiment further explains the straightening roller mechanism 6 , the folding bracket 7 , and the lifting and pushing mechanism 3 .

[0044] The righting roller mechanism 6 includes a connecting bracket 61 perpendicular to the base 1, a Y-shaped roller bracket 62 is arranged on the connecting bracket 61, two righting rollers 63 are arranged on the Y-shaped roller bracket 62, and a V is formed between the two righting rollers 63. shaped notch, which can be better fixed when the oil pipe slides, and avoids the direction to be skewed or even dropped. The bottom of the righting roller 63 is provided with a screw assembly 64 for adjusting the height of the righting roller 63. The screw assembly 64 runs through the Y-shaped roller bracket 62 and The connecting bracket 61 is connected to the base 1 , and the folding bracket 7 is rotatably connected to the connecting bracket 61 . It should be noted that the Y-shaped roller bracket 62 and the ...

Embodiment 3

[0051] On the basis of Embodiment 1, this embodiment further describes the grasping mechanism 4 . Take the lengthwise direction of the base 1 as the X-axis direction, take the width direction of the base 1 as the Y-axis direction, and take the direction perpendicular to the base 1 as the Z-axis direction. The grabbing mechanism 4 includes a Z-axis support 41. The top of the Z-axis support 41 is connected to a telescopic X-axis support arm 43 through a horizontal rotation structure 42. The front end of the X-axis support arm 43 is provided with a liftable Y-axis support arm 44. At least two pairs of grasping grippers 45 are arranged on the Y-axis support arm 44 , the horizontal rotating structure 42 is driven by a rotary stepping motor 46 , and the grasping grippers 45 are driven by a grasping stepping motor 47 .

[0052] When the grasping mechanism 4 is required to grab the oil pipe and put it on the oil pipe support on the side, the rotating stepper motor 46 drives the X-axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com