Energy-saving boiler for industrial production

A boiler and boiler body technology, which is applied in the field of energy-saving boilers for industrial production, can solve the problems of waste of resources, lower performance, and easy blockage, and achieve the effects of reducing power usage, preventing slag accumulation, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

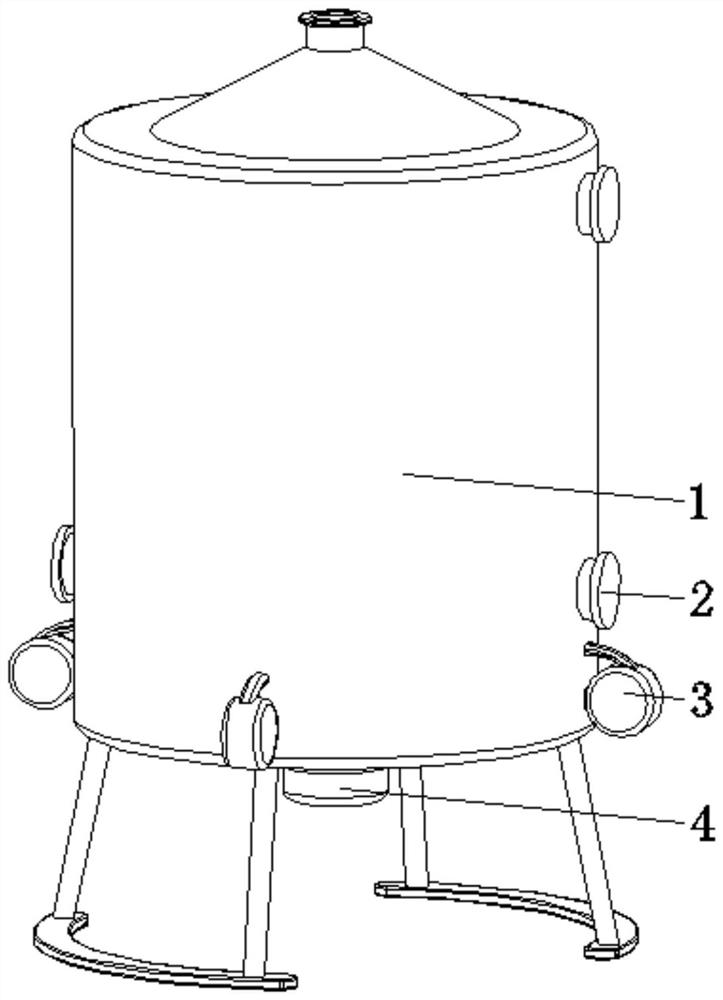

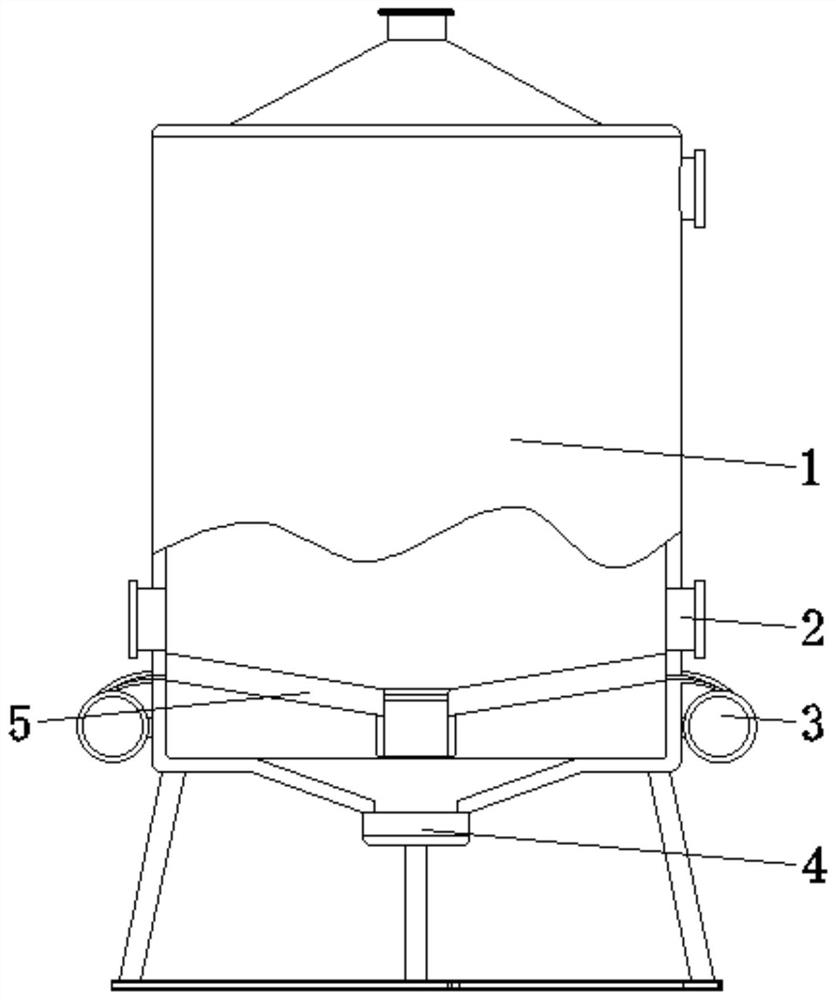

[0031] see Figure 1-7 , the present invention provides a technical solution: an energy-saving boiler for industrial production, including a boiler body 1, a feed port 2, a fan 3, and a discharge port 4, the feed port 2 is arranged on the surface side of the boiler furnace body 1, The fan 3 is fixed on the surface of the boiler body 1 and close to the bottom position, and the discharge port 4 is set at the bottom central position of the boiler body 1;

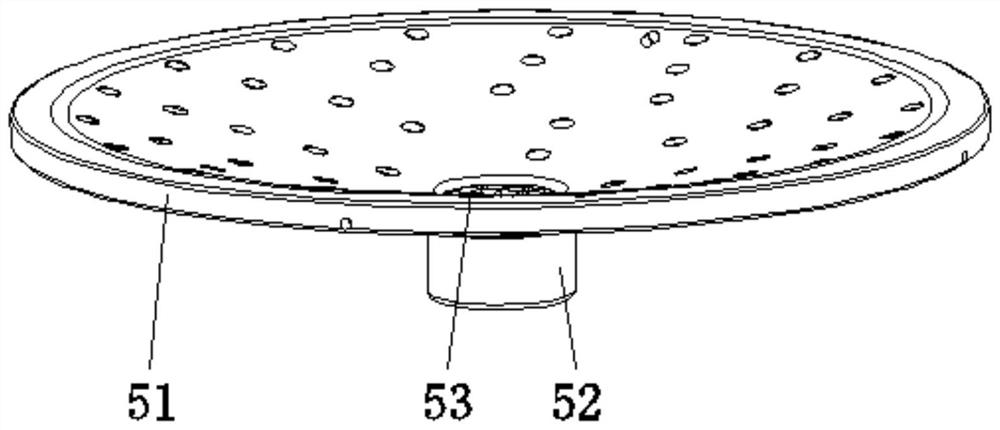

[0032] The inside of the boiler body 1 is provided with a fire grate device 5, the surface edge of the fire grate device 5 is fixedly connected with the inner wall of the boiler body 1, and the fire grate device 5 is provided with a material receiving pan device 51, a slag discharge cylinder 52, and a screen 53. The edge of the surface of the tray device 51 is fixedly connected to the inner wall of the boiler body 1, the slag discharge cylinder 52 is arranged at the bottom center of the tray device 51, and the screen 53 is arra...

Embodiment example 2

[0034] The material receiving tray device 51 is provided with a material receiving tray main body 511, a cavity 512, a plug device 513, a puncture device 514, and a filter screen 515. Inside the tray main body 511 and close to the bottom position, the plugging device 513 is arranged inside the receiving tray main body 511 and at the position of the cavity 512, and the piercing device 514 is arranged inside the receiving tray main body 511 and close to the plugging device 513. position, the filter screen 515 is fixed on the surface of the tray main body 511 and close to the position of the piercing device 514, when the blower fan 3 works, the gas enters the cavity 512, and at this time, as the air pressure continues to increase, the air pressure increases Under the action, the plugging device 513 moves upwards. At this time, air enters the boiler body 1 to provide oxygen for combustion. At the same time, the plugging device 513 will strike the piercing device 514, so that the pi...

Embodiment example 3

[0036]The plugging device 513 is provided with a sealing ball head 5131, a blind hole 5132, and a return spring 5133. The surface bottom of the sealing ball head 5131 is connected with the inside of the receiving tray main body 511, and the blind hole 5132 is provided at the bottom of the sealing ball head 5131. And located in the central position, the return spring 5133 is fixed between the top of the inner wall of the blind hole 5132 and the two sides corresponding to the inside of the receiving tray main body 511. When the air enters the inside of the cavity 512, the air pressure continues to increase. When the spring 5133 is under elastic tension, the sealing ball head 5131 is pushed up by the air pressure, and then hits the filter screen 515 and the piercing device 514, effectively preventing the accumulation of slag, and when the gas is ejected to release the pressure, the elastic tension of the return spring 5133 is greater than At this time, the sealing ball head 5131 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com