Anti-freezing control method for water chilling unit

A technology of chillers and control methods, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of water-side protection temperature sensing lag, prevent refrigerant water freezing failure, ensure continuous operation, and reduce maintenance workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

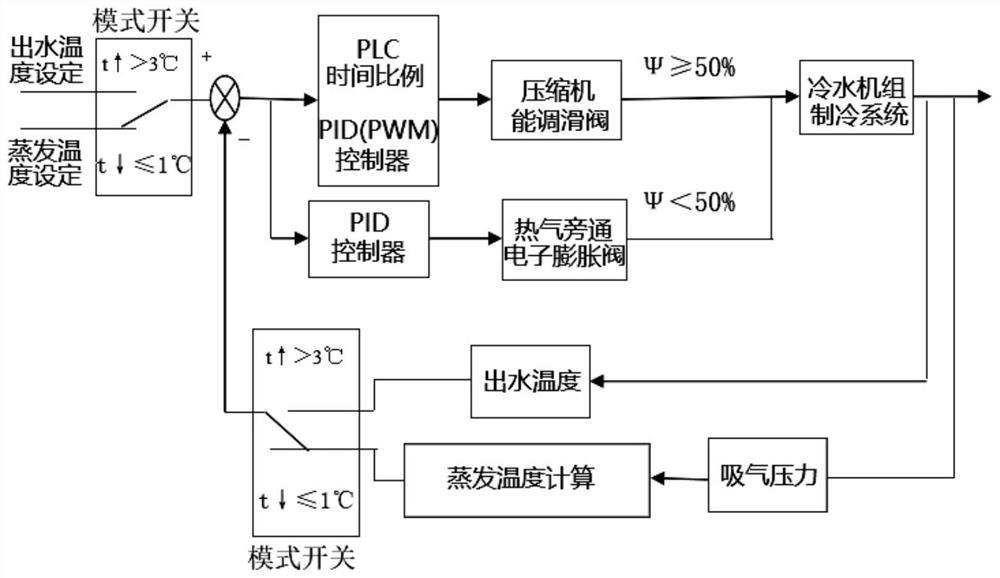

[0014] Such as figure 1 The schematic diagram of the anti-freezing control method of the chiller is shown, and the PLC program is based on the suction pressure P of the refrigeration system of the chiller in real time. a Calculate the evaporation temperature t. When the evaporation temperature t drops to less than or equal to 1°C, the mode switch switches the feedback signal and the set value of the compressor energy regulation control loop to the antifreeze control mode. The antifreeze control mode: when the compressor cooling capacity output is greater than Equal to 50%, that is, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com