Method for effectively detecting tear protein degradation

A technology of tear protein and protein, which is applied to the field of effectively detecting whether tear protein is completely degraded on contact lenses, can solve the problems of impaired vision, incomplete test results, and cannot be used as a professional test basis for quantitative and qualitative detection of protein degradation degree, etc., to achieve The effect of ensuring health and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

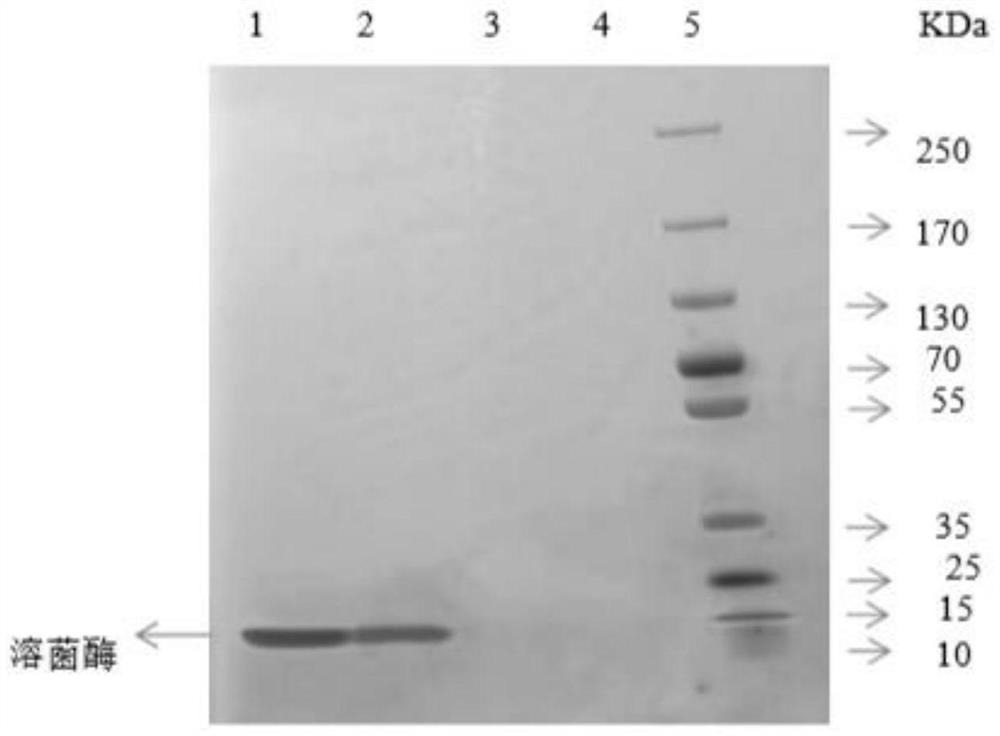

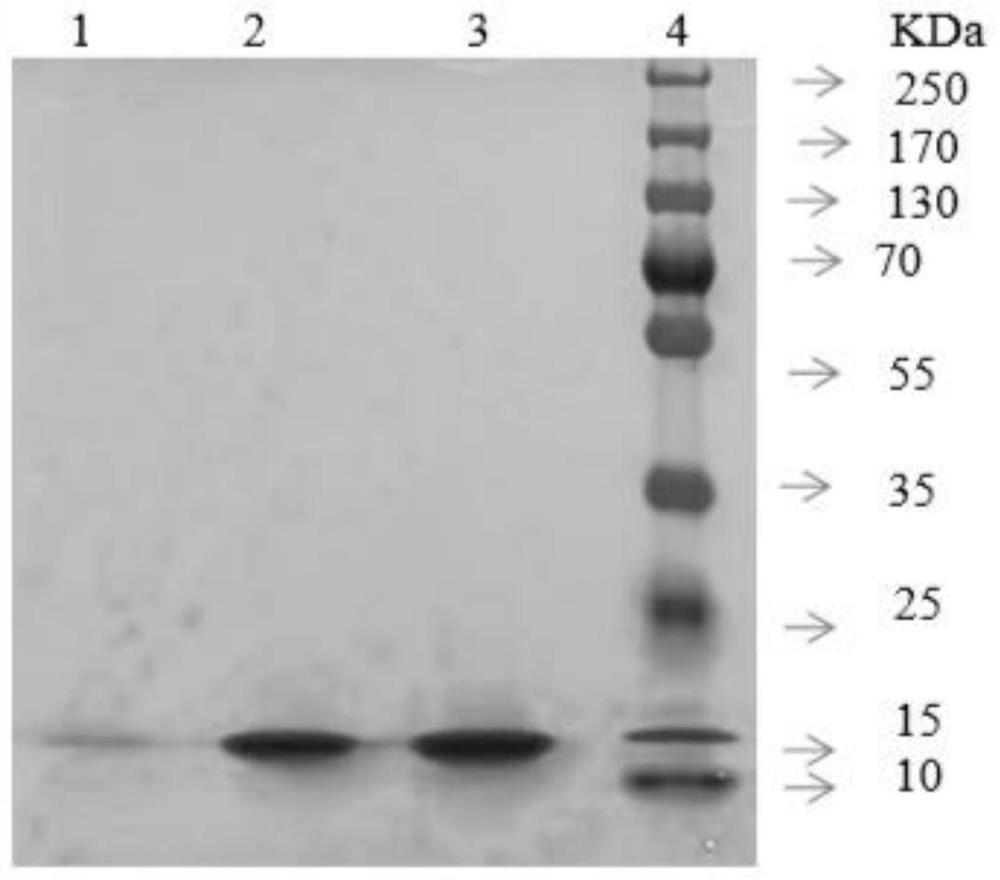

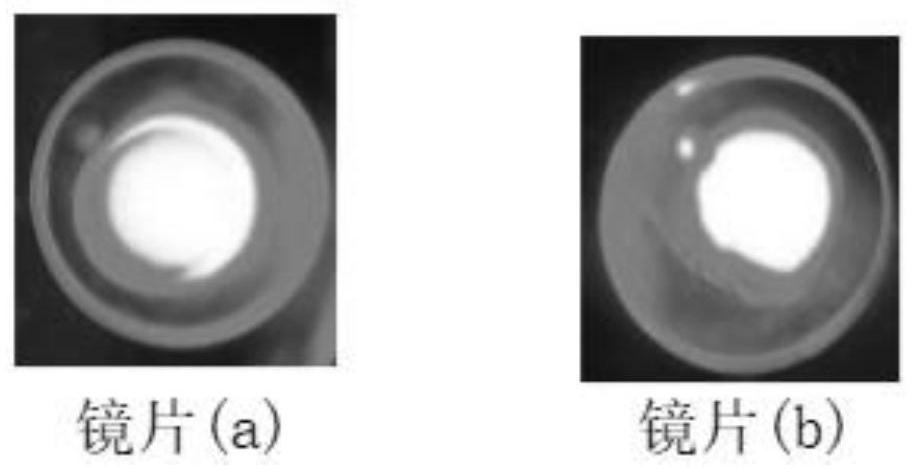

[0040] The method for effectively detecting protein degradation described in the present invention can verify the deproteinization effect of lenses cleaned by contact lens cleaning equipment. To realize the degradation of protein, the degradation principle is as follows:

[0041]The method of electrophoresis dissociation and protein removal is mainly the superposition of protein electrophoresis technology and electrolysis technology. First of all, protein electrophoresis (Electrophoresis) refers to the phenomenon that charged particles or molecules move in an electric field. Macromolecular proteins, polypeptides, virus particles, and even cells or small molecules of amino acids and nucleosides can be oriented in an electric field. Swimming, under the action of the contact lens cleaner of the present invention, the lacrimal protein is charged, and moves toward the position of the probe electrode under the action of the probe field strength in the lens cleaning tank of the clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com