A method for the analysis of thiophene in water by purge and trap gas chromatography

A purge-and-trap and GC-MS technology, applied in the field of testing, can solve problems such as operational hazards, gas chromatographic columns that are not suitable for direct analysis of water samples, and difficult to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

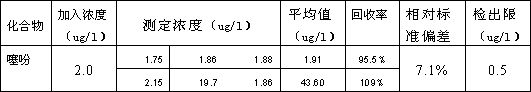

Image

Examples

Embodiment Construction

[0012] The method for analyzing thiophene in water by purging and trapping GC-MS of the present invention comprises the following steps:

[0013] Step 1. Collect a water sample and add 10ml methanol as a preservative to the 1000ml water sample, add 20ml water sample to the sample bottle, add 0.2g sodium chloride to the sample bottle, shake it gently to dissolve it, and then add 40ug / ml of 1,4-difluorobenzene solution 5ul of internal standard solution and capped;

[0014] Step 2. Place the sample vial in the purge and trap injector, and set the purge and trap conditions as follows: transmission temperature 140°C, purge flow 40ml / min, sample volume 10ml, purge waiting flow 10ml / min, sample purge The purge time is 11min, the sample purge temperature is 20℃, the drying purge time is 2min, the drying purge flow rate is 10ml / min, and the drying purge temperature is 20℃;

[0015] Step 3. Start the purge and trap injector to purge and trap the sample bottle, and the thiophene in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com