Method for testing content and consumption of electrolyte in battery

A test method and electrolyte technology, applied in the direction of removing certain components such as weighing, measuring devices, instruments, etc., can solve the problem of inaccurate calculation, and achieve accurate proportion results, less solvent consumption, and accurate electrolyte content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for testing the consumption of electrolyte in a battery. The battery to be tested is a 5Ah soft-pack battery, and the electrolyte injection volume of the battery is m 1 = 17.7g, the above-mentioned battery is used for testing after 1000 cycles, and the testing process is as follows:

[0036] Put the battery in the glove box and weigh the mass of the battery as m 2 =80.92g, make a gap on the side of the battery, and put the battery gap upwards, dry the volatile components of the electrolyte in the battery electrode group in an oven at 60°C until the battery mass no longer decreases, and test at this time Battery weight m 3 = Weight m of volatile components in 73.82g electrolyte 挥发 for m 2 -m 3 = 7.10 g.

[0037] Take the separator to wrap the battery that has been baked out of volatile components, and inject m 4 =25.01g of high-purity solvent DMC, sealed and placed in a high temperature state of 60°C, and left to stand for 48 hours. Make the high-purity s...

Embodiment 2

[0045] A test method for electrolyte content in a battery, the battery to be tested is a 5Ah soft-pack battery, and the electrolyte injection volume of the battery is m 1 = 17.55g, the above-mentioned battery is directly tested by the method in Example 1 before use, the testing process is exactly the same as that of Example 1, and the testing results are shown in Table 2.

[0046] Table 2

[0047] m 挥发

[0048] From the above test results, it can be known that the electrolyte injection volume m 1 and the detected m 电解液 There is little difference in content, which further proves the accuracy of the detection result of the present invention.

Embodiment 3

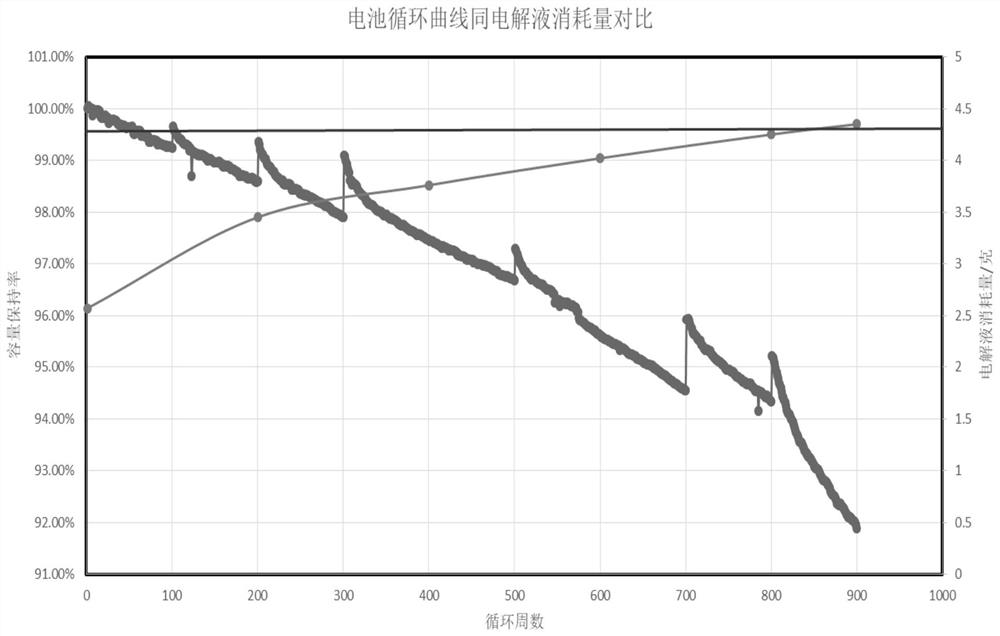

[0050] In this embodiment, the method in Example 1 is used to analyze whether the capacity of the battery with a diving battery is caused by insufficient electrolyte, so as to determine whether the injection volume of the battery electrolyte meets the battery cycle life requirements. The specific process is as follows:

[0051] Step 1. Prepare the same batch of batteries, and cycle them for different weeks according to the same cycle conditions until the battery dives;

[0052] Step 2, for batteries with different cycle numbers, detect the consumption m of the electrolyte according to the method in Example 1 消耗 ;

[0053] Step 3. Obtain the number of battery cycles and the consumption of electrolyte m 消耗 The relationship diagram between, such as figure 1 shown.

[0054] pass figure 1 From the results, it can be seen that the test method for electrolyte consumption in a battery disclosed in the present invention can be used to accurately determine whether the injection volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com