Direct current brushless motor based on magnetic coupling resonance and control method thereof

A DC brushless motor, magnetic coupling resonance technology, applied in the direction of single motor speed/torque control, connection with control/drive circuit, electric components, etc., can solve the problem of reducing the service life and reliability of the motor, reducing the service life of the motor and Efficiency, brush and commutator mechanical wear and other issues, to achieve the effect of small vibration, improve operating efficiency, reduce noise and resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

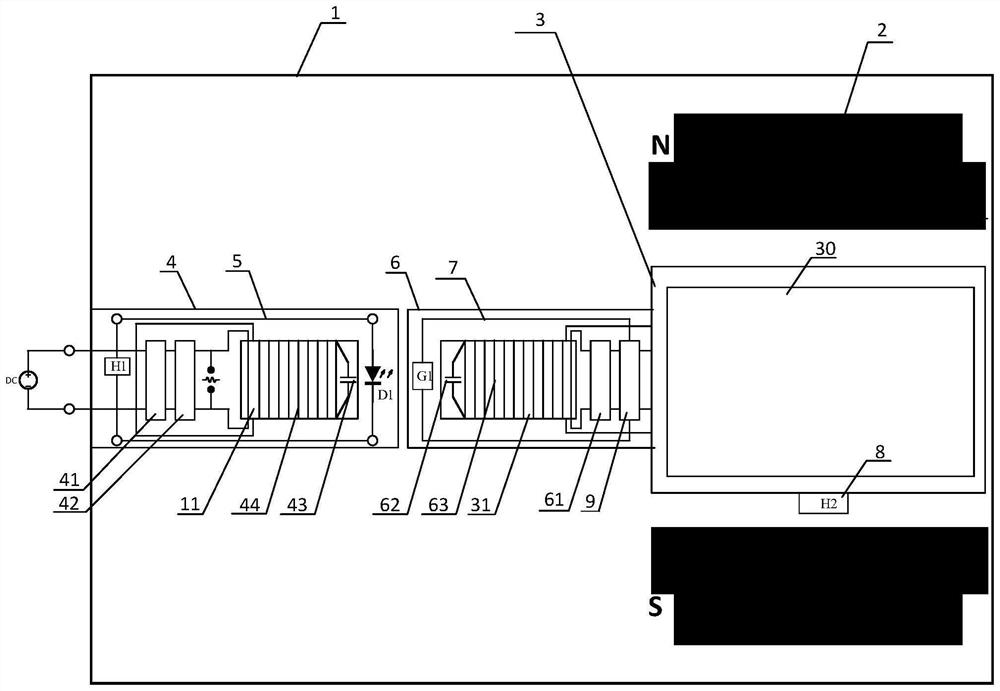

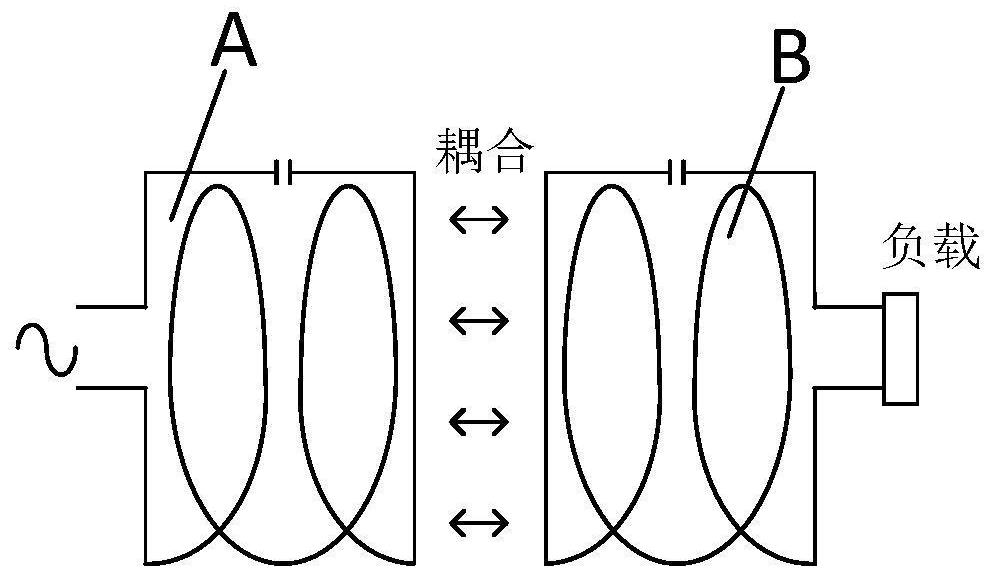

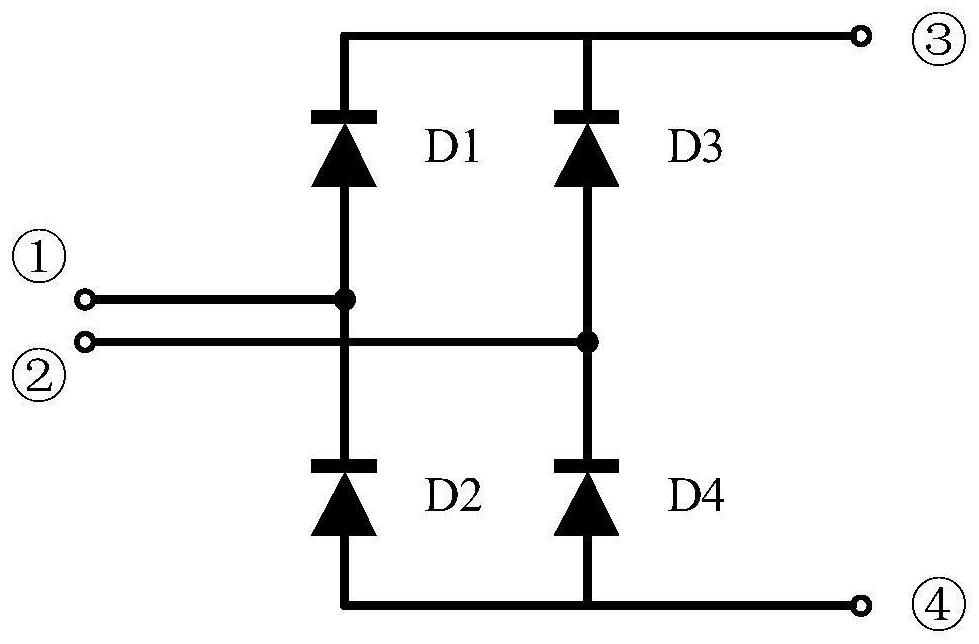

[0032] Such as figure 1 As shown, the brushless DC motor based on magnetic coupling resonance in this embodiment includes a casing 1 and a stator 2 and a rotor 3 respectively arranged in the casing 1, and a wireless power supply module 4 and an input current direction detection circuit 5 are arranged inside the casing 1. The rotor 3 is provided with a wireless receiving module 6, an input current direction sensing circuit 7, a rotation position detection module 8, a rotor armature drive module 9 and a rotor armature 30, and the wireless energy supply module 4 and the wireless receiving module 6 are arranged adjacently In order to realize the wireless power transmission based on magnetic coupling resonance, the input current direction detection circuit 5 and the input current direction sensing circuit 7 are adjacently arranged to realize the wireless transmission of the input current direction detection signal, and the energy output terminal of the wireless receiving module 6 pa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap