Cap system for a concentrated refill capsule

A technology for refilling and capping components, applied in the field of cap systems, which can solve the problems of damage to household products, poor cleaning results, health hazards of concentrated cleaning fluids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

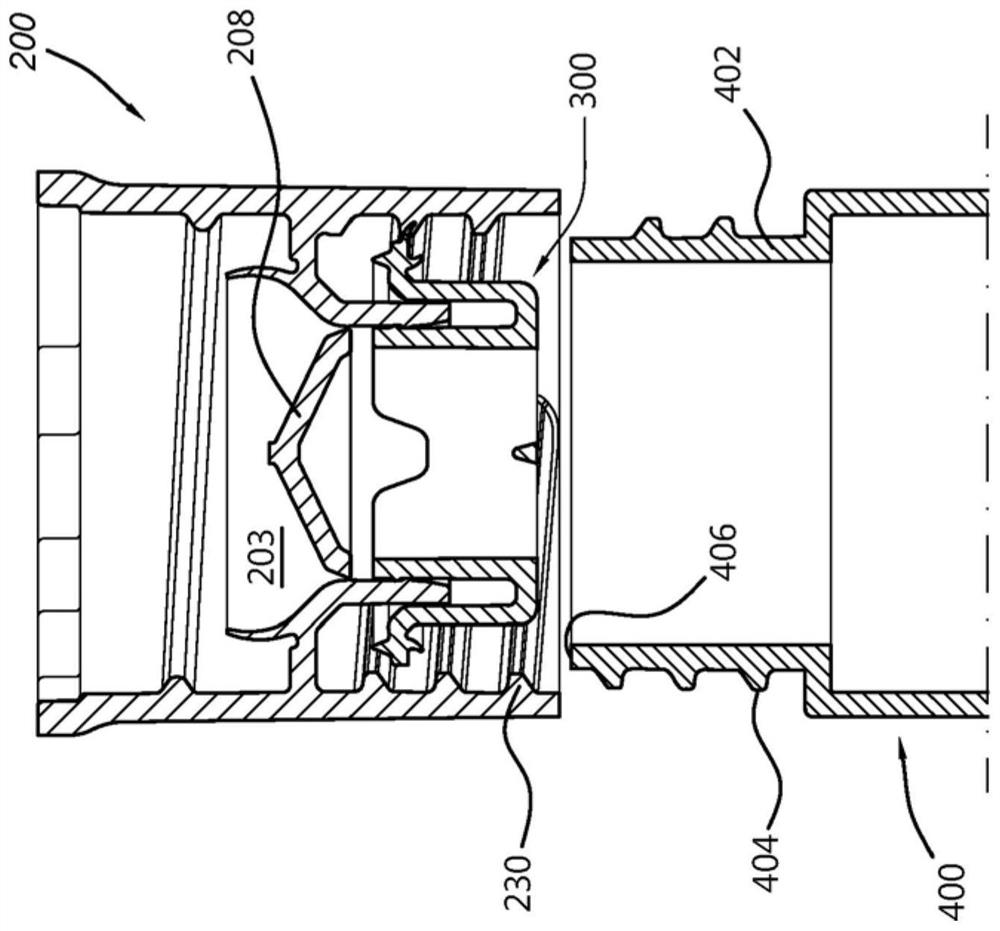

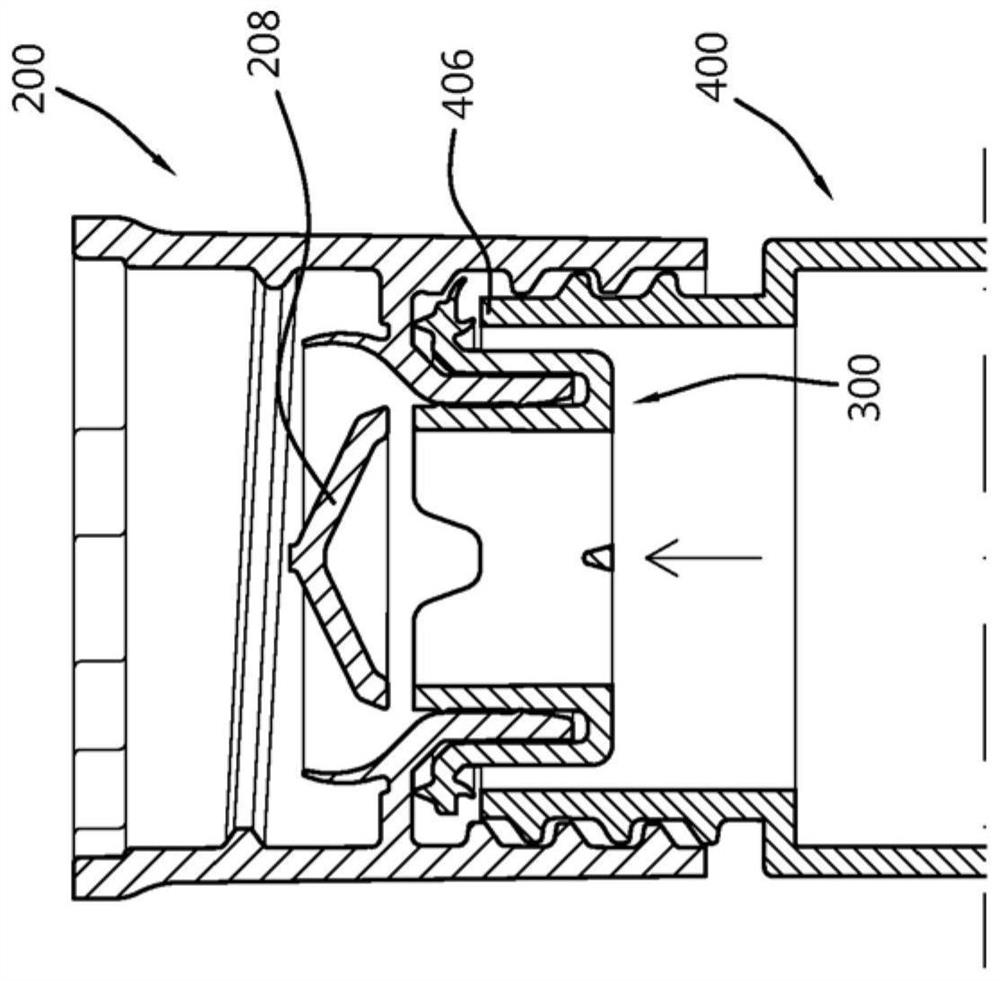

[0070] In the detailed description of the drawings, like numerals are used to denote like features of the various exemplary apparatus according to the present invention.

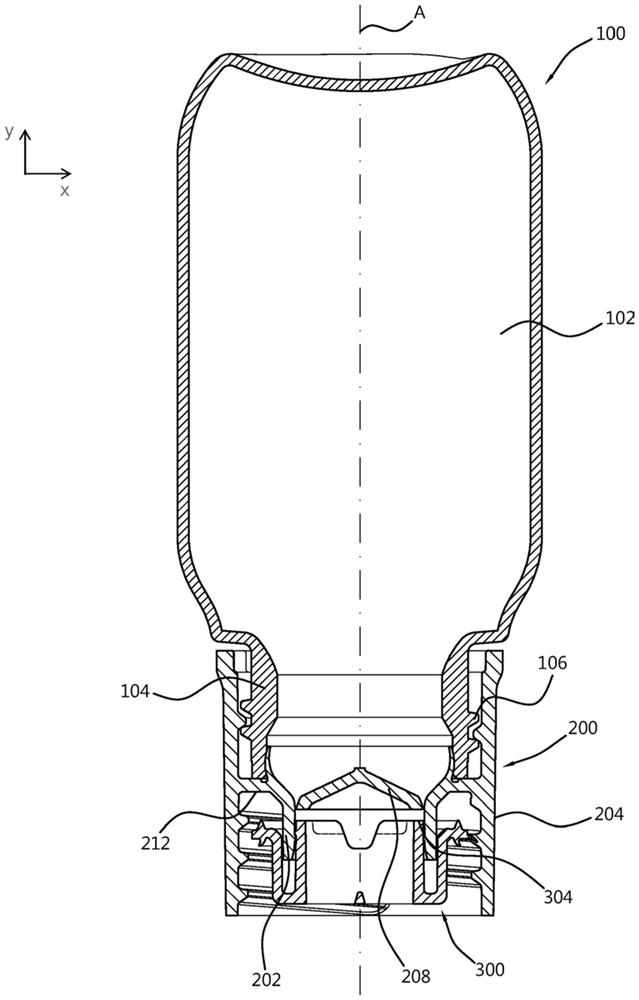

[0071] figure 1 Shows a concentrated cleaning fluid and accommodating the refill system configured for use with a refillable container. figure 1 100 shows, a sectional view of the refill 200 and the system 300 of the assembled plug assembly comprises a balloon cover body.

[0072] like figure 1 As shown in the balloon 100 the receiver comprises a substantially hollow body, the receiver is configured to receive a volume of cleaning fluid was concentrated. Concentrated cleaning fluid 102 contained within the interior volume 100 of the bladder body. Bladder neck portion 104 includes a body 100, neck portion 104 includes an open end 108 surrounded by the rim. A threaded neck portion 104 comprises a balloon 106, the balloon 106 is threaded configured to engage corresponding threads 200 on the cap assembly.

[0073] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com