Coffee coated processed cheese and preparation method thereof

A technology for processing cheese and coffee, which is applied in the field of coffee smearing and processing cheese and its preparation, and achieves the effects of improving economic benefits, broadening consumer groups, and having delicious taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

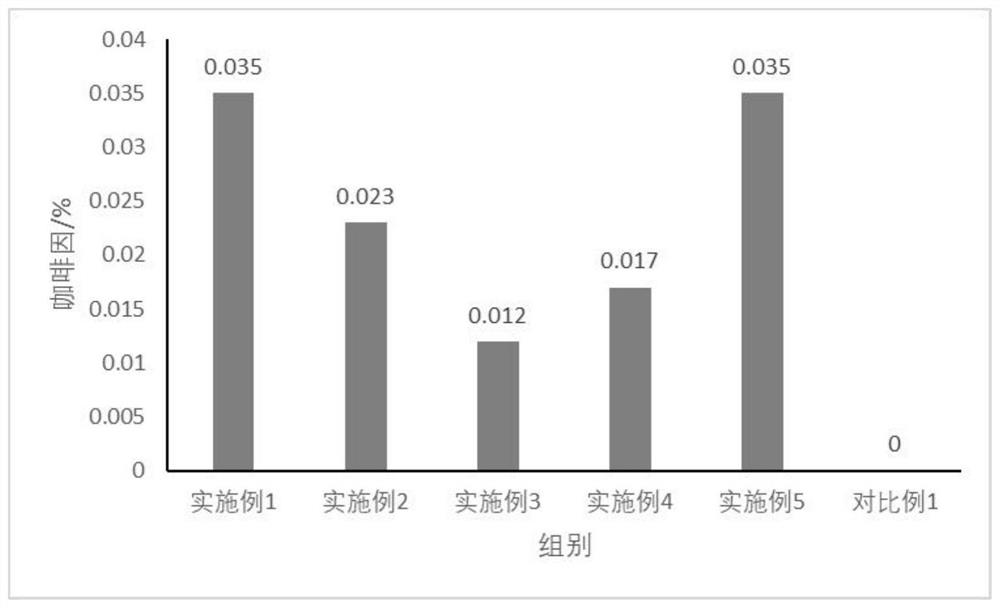

Examples

preparation example Construction

[0029] A method for preparing processed cheese spread with coffee provided by the invention comprises the following steps:

[0030] (1) Add cheddar cheese to butter, stabilizer, emulsifying salt, coffee powder, salt and water to melt the mixture and heat it, keep warm and stir to fully hydrate;

[0031] (2) Heat and sterilize the uniformly stirred material;

[0032] (3) Aseptically homogenize the sterilized material while hot;

[0033] (4) The homogenized material obtained in step (3) is aseptically filled while hot, and cooled at room temperature.

[0034] In the preparation method of the coffee smear processed cheese of the present invention, there is no special limitation on the mixing method of the raw materials, and the known mixing method in the art can be used for preparation. In the present invention, the heating temperature in step (1) is 50-60°C, preferably 55°C, the heat preservation and stirring time is 3-5min, preferably 4min, and the stirring speed is 200-500rp...

Embodiment 1

[0042] A coffee smear processed cheese comprises the following raw materials in weight percentage: 25% cheddar cheese, 1.5% emulsifying salt, 0.5% table salt, 0.1% locust bean gum, 3.0% coffee powder, 20% butter, and the balance is water.

[0043] The preparation method of the coffee smear processed cheese comprises the following steps:

[0044] (1) Take the above-mentioned raw materials according to the batching ratio, heat them to 60° C., and mix and stir at a speed of 500 rpm for 3 minutes to obtain a mixture;

[0045] (2) Heat the material to 90°C and then keep it warm for 5 minutes;

[0046] (3) Aseptically homogenize the sterilized material while it is hot, and the homogenization pressure is 20MPa;

[0047] (4) The homogenized material obtained in step (3) is aseptically filled while hot, and cooled at room temperature.

Embodiment 2

[0049] A coffee smear processed cheese comprises the following raw materials in weight percentage: 15% cheddar cheese, 1.0% emulsifying salt, 1.0% table salt, 0.4% pectin, 2.0% coffee powder, 35% butter, and the balance is water.

[0050] The preparation method of the coffee smear processed cheese comprises the following steps:

[0051] (1) Take the above-mentioned raw materials according to the batching ratio, heat them to 50° C., and mix and stir at a speed of 300 rpm for 4 minutes to obtain a mixture;

[0052] (2) Heat the material to 80°C and then keep it warm for 8 minutes;

[0053] (3) The sterilized material is aseptically homogenized while it is hot, and the homogenization pressure is 18MPa;

[0054] (4) The homogenized material obtained in step (3) is aseptically filled while hot, and cooled at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com