Following juice machine

A juicer and juice collection technology, which is used in household machinery, household appliances, and applications for filtering food, can solve the problems that users cannot squeeze a large amount of juice at one time, cannot achieve continuous juicing, and is troublesome to clean. Reduced, weight-saving, easy-to-clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

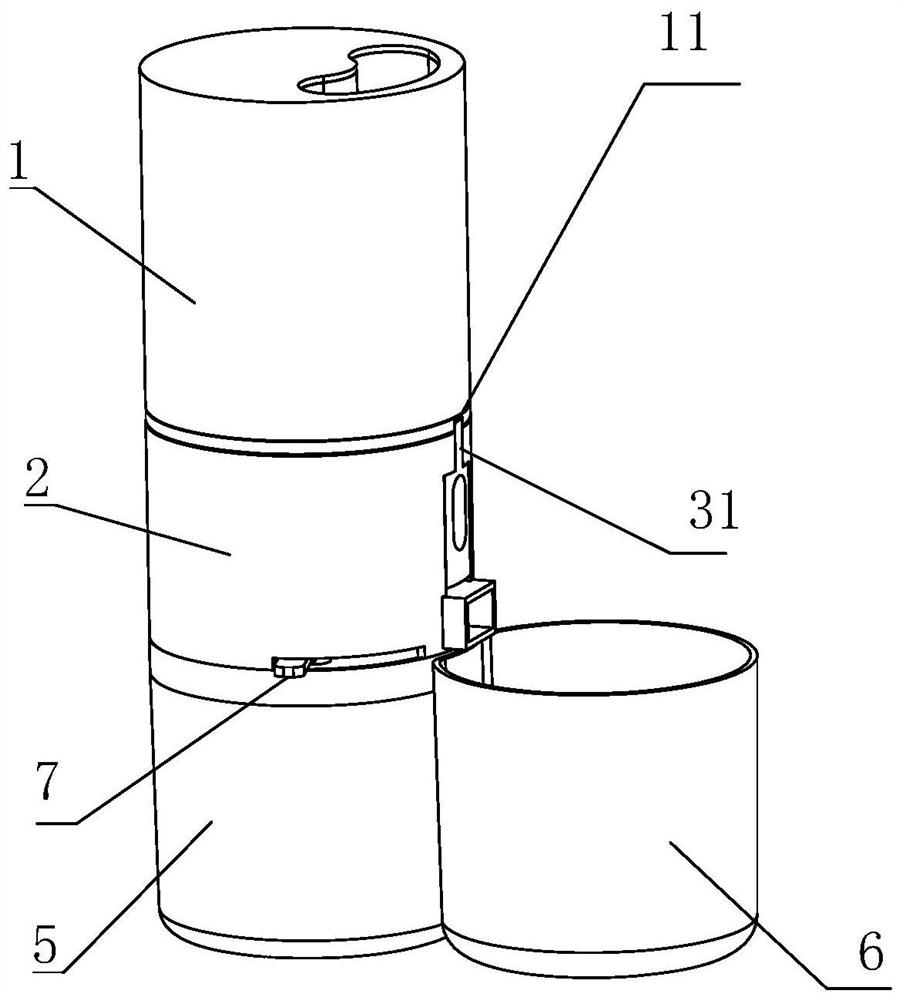

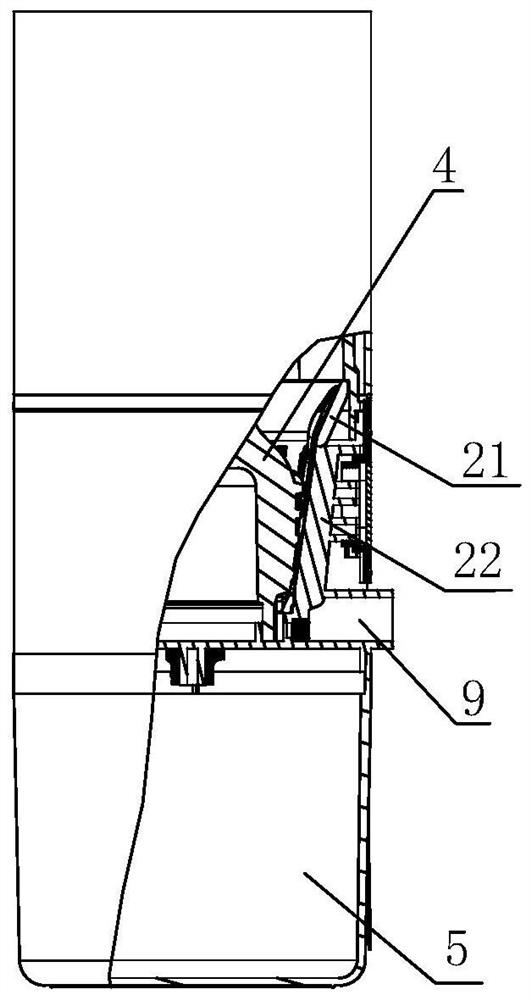

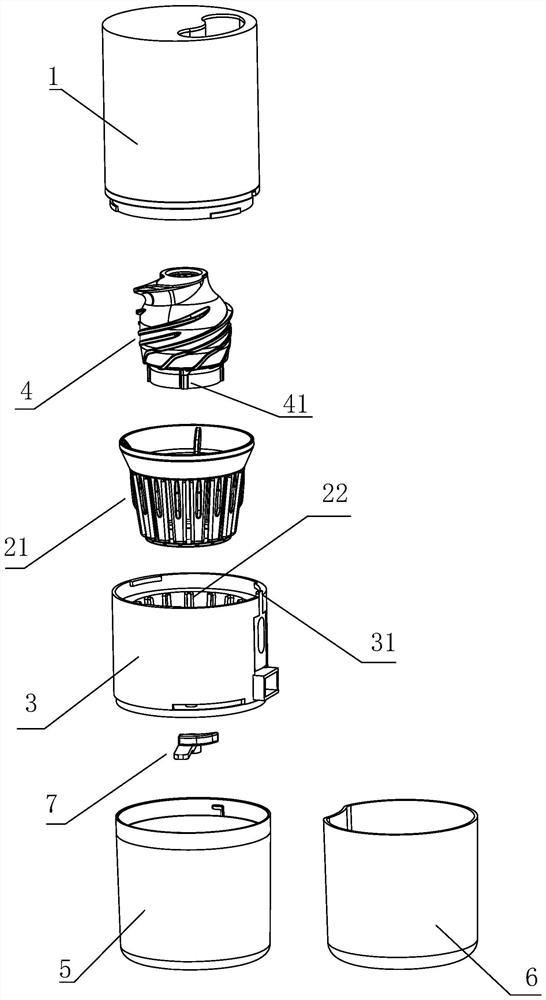

[0046] Such as Figure 1-Figure 3 As shown, this embodiment provides a portable raw juice machine, including a screw 4, a juice extraction assembly 2 and a host 1 arranged above the juice extraction assembly 2, the host 1 is provided with a feed channel and for A motor that drives the juice extraction assembly 2 to work. The juice extraction assembly 2 includes a juice collection chamber 3 and a juice extraction cylinder arranged in the juice collection chamber 3. The juice extraction cylinder includes a juice outlet cylinder 22 and a juice extraction cylinder arranged in the The extrusion cylinder 21 in the juice outlet cylinder 22, the screw 4 is arranged in the extrusion cylinder 21, the extrusion cylinder 21 is nested in the juice outlet cylinder 22, and the juice extraction assembly 2 also includes an outlet The slag channel 9 and the juice outlet channel 8, the slag outlet channel 9 and the juice outlet channel 8 are vertically arranged, so that at least one of the slag ...

Embodiment 2

[0059] The difference between this embodiment and Embodiment 1 is that the juicing cylinder includes a cylinder body and a filter mesh set on the cylinder body, and the material is squeezed and ground by the screw 4 and the juice extraction cylinder to form fruit juice and pomace, so The cylinder body is provided with a slag outlet, and the slag outlet extends horizontally outward to form the slag outlet channel 9, and the slag outlet channel 9 passes through the through hole arranged on the side wall of the juice collection chamber 3, so that the slag outlet channel 9 communicates with the outside world, and the pomace is discharged outward through the slag discharge channel 9 to realize continuous slag discharge.

[0060] The juice flows into the juice collection space after being filtered by the filter mesh. Since the juice outlet channel and the slag outlet channel 9 are vertically arranged, the juice outlet channel is arranged along a vertical plane. A juice outlet is pro...

Embodiment 3

[0063] Such as Figure 9-Figure 11As shown, the difference between this embodiment and Embodiment 1 is that the juicer also includes a slag receiving cup 6, which is detachably arranged under the juice extracting assembly 2, and the juice extracting The bottom of the assembly 2 is provided with a slag outlet 91, the opening of the slag outlet is downward to form the slag outlet channel 9, the slag outlet 91 is connected with the slag receiving cup 6, and the slag outlet 91 is located at the In the vertical projection of the juice outlet cylinder 22, the pomace can smoothly fall into the slag receiving cup 6 from the slag discharge channel due to gravity, and the slag discharge rate is fast. On the side wall of the slag discharge channel for easy cleaning. The slag discharge baffle 71 can rotatably cover part or all of the slag discharge port 91 to adjust the degree of opening and closing of the slag discharge port 91 to ensure the slag discharge resistance of the juicer to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com