Stable cleaning products containing glycine-based surfactant

A technology for surfactants and cleaning products, applied in skin care preparations, medical preparations containing active ingredients, cosmetics, etc., can solve problems such as inability to thicken and difficult thickening of glycine-type surfactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

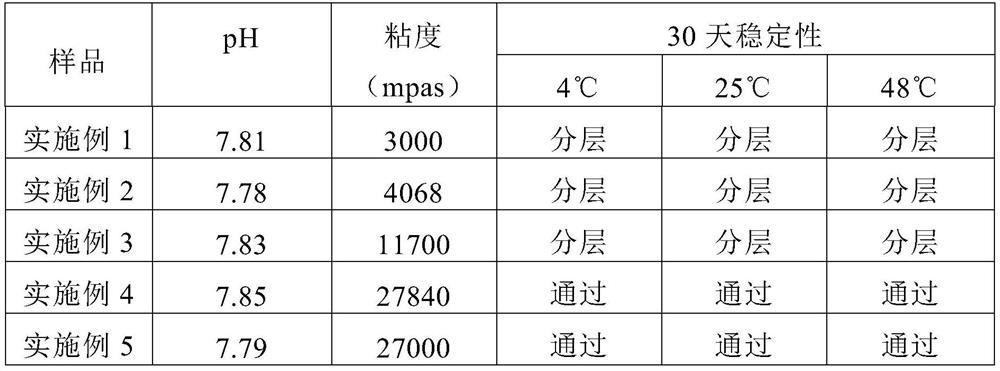

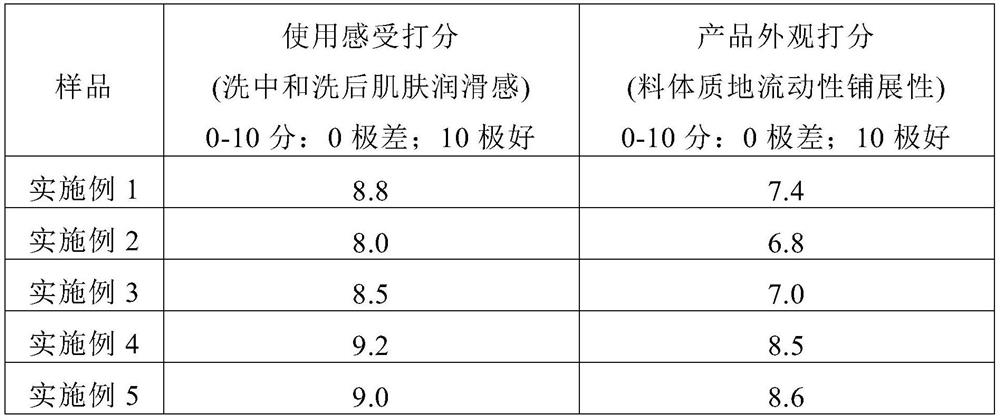

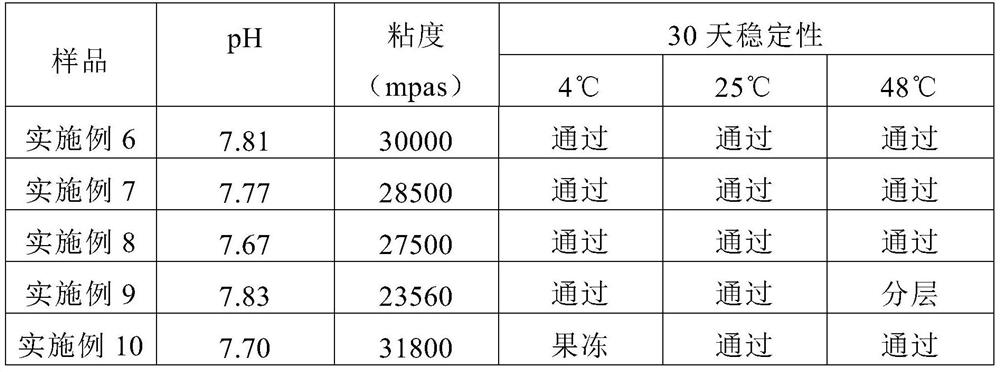

Examples

Embodiment 1

[0076] Example 1: Preparation of Cleaning Products

[0077] Weigh 0.05 parts by mass of polyethylene glycol-14M and 0.1 parts by mass of glycerin and mix them evenly, add them into a beaker containing 40 parts by mass of deionized water, heat to 75-80°C and mix and stir at a speed of 100rpm until completely dissolved; add 25 mass parts of sodium cocoyl glycinate (30% active content) and 0.5 mass parts of p-hydroxyacetophenone are stirred; the myristic acid of 1.5 mass parts and the stearic acid of 1.5 mass parts are added in the beaker, and the temperature is raised to Mix and stir at 80-85°C at a speed of 150rpm until it is completely dissolved and the material is transparent; cool down to 70-75°C and add 12 parts by mass of sodium lauroamphoacetate and 12 parts by mass of cocamidopropyl sulfobetaine and stir evenly ; Cool down to 40-45°C and add 0.5 parts by mass of phenoxyethanol, and use an appropriate amount of potassium hydroxide to adjust the pH, make up the balance to ...

Embodiment 2

[0078] Example 2: Preparation of Cleaning Products

[0079] Weigh 0.05 parts by mass of polyethylene glycol-14M and 0.1 parts by mass of glycerin and mix them evenly, add them into a beaker containing 40 parts by mass of deionized water, heat to 75-80°C and mix and stir at a speed of 100rpm until completely dissolved; add 25 mass parts of sodium cocoyl glycinate (30% active content) and 0.5 mass parts of p-hydroxyacetophenone are stirred; the myristic acid of 1.5 mass parts and the stearic acid of 1.5 mass parts are added in the beaker, and the temperature is raised to Mix and stir at 80-85°C at a speed of 150rpm until it is completely dissolved and the material is transparent; cool down to 70-75°C and add 12 parts by mass of sodium lauroamphoacetate and 12 parts by mass of cocamidopropyl sulfobetaine and stir evenly ; Cool down to 40-45°C, add 0.5 parts by mass of phenoxyethanol and 0.5 parts by mass of sodium chloride, and use an appropriate amount of potassium hydroxide to ...

Embodiment 3

[0080] Example 3: Preparation of Cleaning Products

[0081] Weigh 0.05 parts by mass of polyethylene glycol-14M and 0.1 parts by mass of glycerin and mix them evenly, add them into a beaker containing 35 parts by mass of deionized water, heat to 75-80°C and mix and stir at a speed of 100rpm until completely dissolved; add 25 mass parts of sodium cocoyl glycinate (30% active content) and 0.5 mass parts of p-hydroxyacetophenone are stirred; the myristic acid of 1.5 mass parts and the stearic acid of 1.5 mass parts are added in the beaker, and the temperature is raised to Mix and stir at 80-85°C at a speed of 150rpm until it is completely dissolved and the material is transparent; cool down to 70-75°C and add 12 parts by mass of sodium lauroamphoacetate and 12 parts by mass of cocamidopropyl sulfobetaine and stir evenly ; Cool down to 60-65°C and add 4 parts by mass of deionized water and 4 parts by mass of acrylic acid (ester) copolymer mixture, and disperse evenly under the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com