CdS quantum dot modified bismuth composite material as well as preparation method and application thereof

A technology of composite materials and quantum dots, which is applied in the field of CdS quantum dot modified bismuth-based composite materials and its preparation, can solve the problems of CdS quantum dot agglomeration and less active crystal faces, so as to promote separation, promote rapid separation, and broaden visible light Effect of Response Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

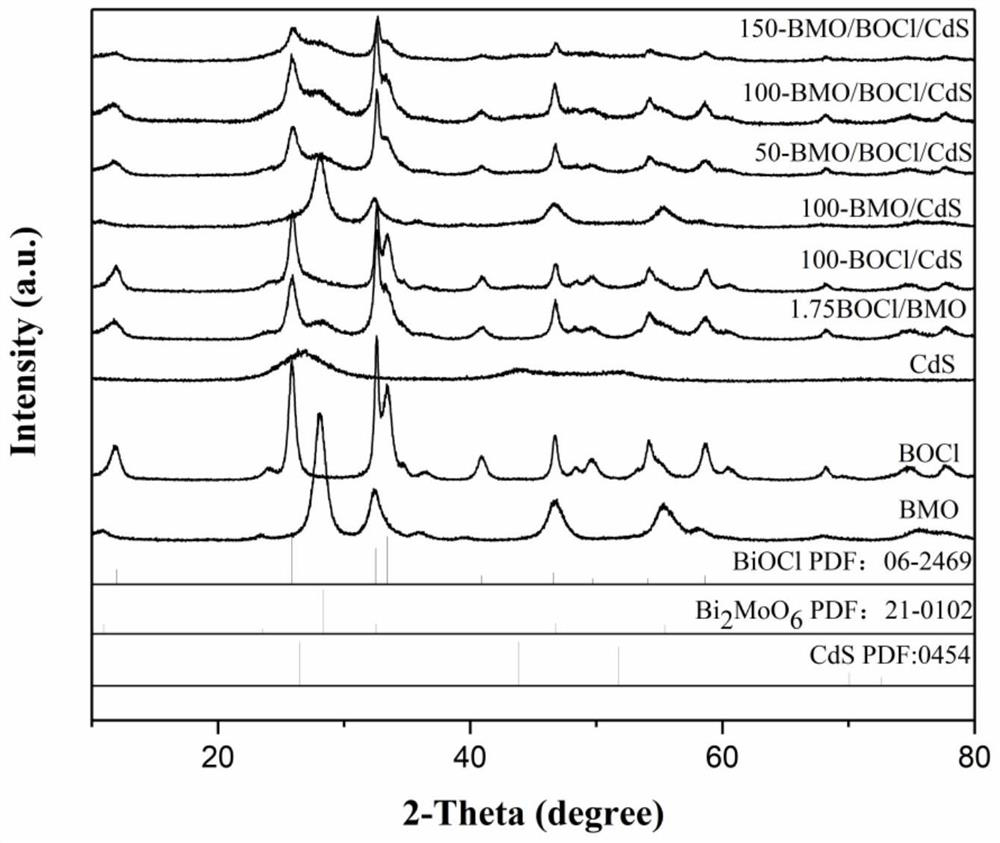

[0033] (1) BiOCl / Bi 2 MoO 6 Preparation of Nanospheres

[0034] Take Bi(NO 3 ) 3 ·5H 2 O (1mmol), Na 2 MoO 4 2H 2 O(2mmolNa 2 MoO 4 2H 2 O) and NaCl (1.75mmol) were added in 15 milliliters of ethylene glycol respectively, and ultrasonically dispersed for 60min;

[0035] The dispersed three groups of solutions were mixed together and ultrasonically treated for 10 min, and then placed in a microwave-assisted synthesizer to prepare BiOCl / Bi 2 MoO 6 ;

[0036] Finally, the product was collected, washed several times with deionized water and ethanol, and then dried at 60 °C for 12 h. The product was collected and labeled as 1.75-BOCl / BMO;

[0037] (2) BiOCl / Bi 2 MoO 6 / Preparation of CdS nanospheres

[0038] 114mg of CdCl 2 Add to 20ml (0.08mol / L) CTAB aqueous solution;

[0039] 38 mg of thioacetamide and 50 mg of 1.75-BOCl / BMO were added to another 20 ml portion of CTAB in water;

[0040] The two solutions were dispersed under ultrasonic conditions for 10 minutes...

Embodiment 2

[0042] (1) BiOCl / Bi 2 MoO 6 Preparation of Nanospheres

[0043] Take Bi(NO 3 ) 3 ·5H 2 O (1mmol), Na 2 MoO 4 2H 2 O(2mmolNa 2 MoO 4 2H 2 O) and NaCl (1.25mmol) were added in 15 milliliters of ethylene glycol respectively, and ultrasonically dispersed for 60min;

[0044] The dispersed three groups of solutions were mixed together and ultrasonically treated for 10 min, and then placed in a microwave-assisted synthesizer to prepare BiOCl / Bi 2 MoO 6 ;

[0045] Finally, the product was collected, washed several times with deionized water and ethanol, and then dried at 60 °C for 12 h. The product was collected and labeled as 1.25-BOCl / BMO;

[0046] (2) BiOCl / Bi 2 MoO 6 / Preparation of CdS nanospheres

[0047] 114mg of CdCl 2 Add to 20ml (0.05mol / L) CTAB aqueous solution;

[0048] Add 38mg of thioacetamide and 100mg of 1.25-BOCl / BMO to another 20ml (0.05mol / L) CTAB aqueous solution;

[0049] The two solutions were dispersed under ultrasonic conditions for 10 minut...

Embodiment 3

[0051] (1) BiOCl / Bi 2 MoO 6 Preparation of Nanospheres

[0052] Take 1mmol Bi(NO 3 ) 3 ·5H 2 O, 2 mmol Na 2 MoO 4 2H 2 Add O and 2mmol NaCl to 15ml of ethylene glycol respectively, and ultrasonically disperse for 60min;

[0053] The dispersed three groups of solutions were mixed together and ultrasonically treated for 10 min, and then placed in a microwave-assisted synthesizer to prepare BiOCl / Bi 2 MoO 6 ;

[0054] Finally, the product was collected, washed several times with deionized water and ethanol, and then dried at 60 °C for 12 h to collect the product and label it as 2-BOCl / BMO;

[0055] (2) BiOCl / Bi 2 MoO 6 / Preparation of CdS nanospheres

[0056] 114mg of CdCl 2 Add to 20ml (0.1mol / L) CTAB aqueous solution;

[0057] Add 38mg of thioacetamide and 150mg of 2-BOCl / BMO to another 20ml (0.1mol / L) CTAB aqueous solution;

[0058] The two solutions were dispersed under ultrasonic conditions for 10 minutes and then mixed, and then 1.5 ml of cyclohexane was ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com