New energy automobile charger water channel sealing process and structure

A new energy vehicle, sealing structure technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve problems such as short circuit burning of internal electronic components, improve processing efficiency, facilitate effective curing, and improve sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

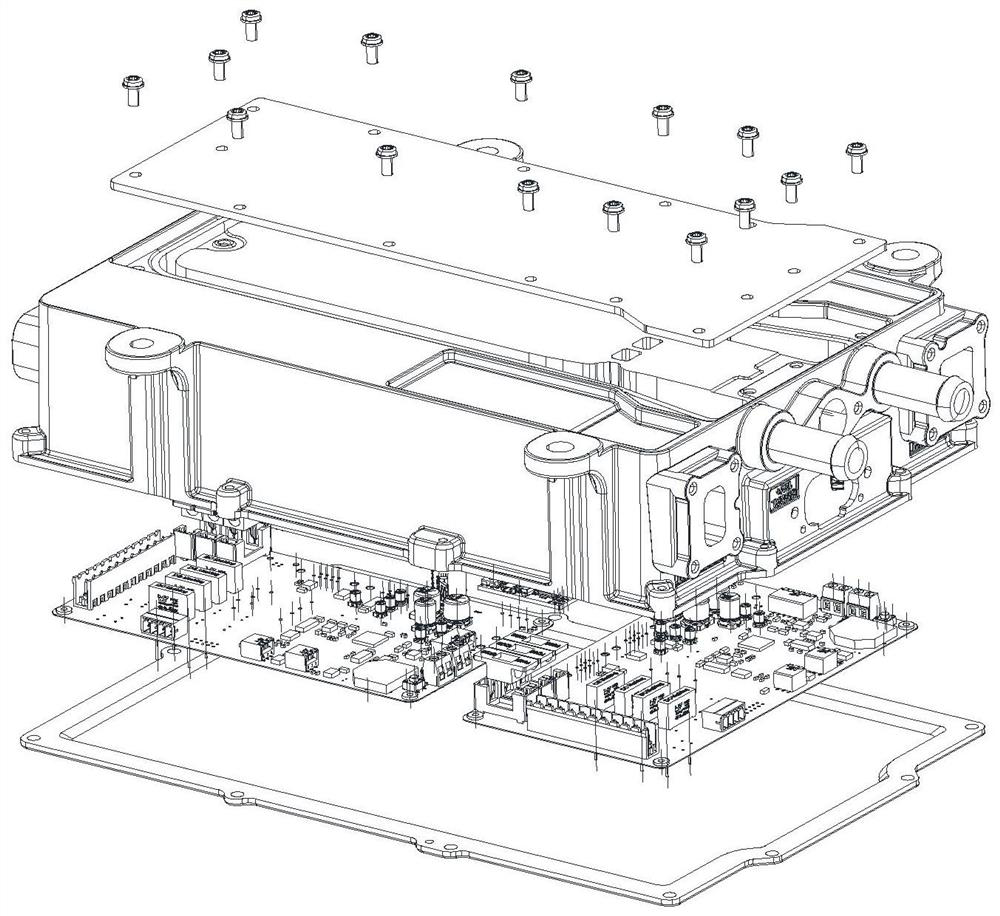

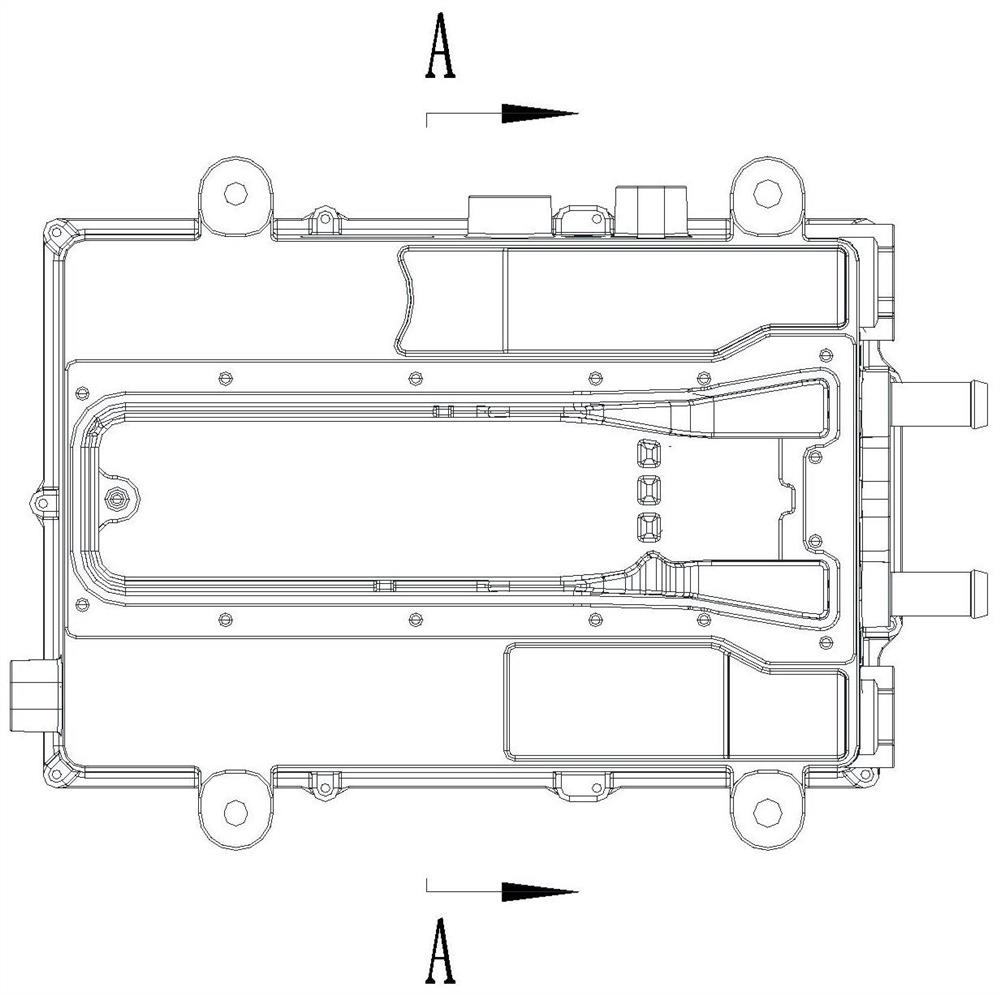

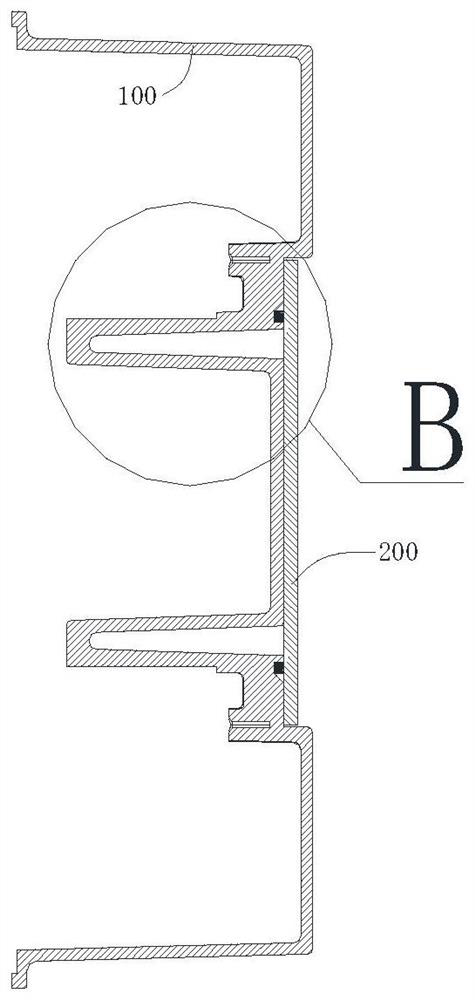

[0044] a kind of like Figure 1-Figure 6 The shown new energy vehicle charger water channel sealing process is used to seal the charger box 100 and the water channel cover plate 200 and make the water channel 300 a sealed circuit, which includes the following steps,

[0045] S1. Machining. A sol tank 400 is processed along the water channel 300 on the mating surface of the water channel cover plate 200 of the charger case 100. The sol tank 400 is located at the root of the water channel 300 and communicates with it. The bottom side of the sol tank 400 has a A C-angle structure 401 inclined in the direction of the waterway 300, the C-angle structure 401 is a transitional structure with a slope or an arc;

[0046] S2. Glue dispensing, in a constant temperature and humidity environment, continuously dispense sealant 500 in the sol tank 400 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com