High-carbon ferro-chrome powder processing technology and production line for processing high-carbon ferro-chrome powder

A high-carbon ferrochromium and processing technology, which is applied in the field of high-carbon ferrochromium powder processing technology and production line for high-carbon ferrochromium powder processing, can solve the problems of inconsistent thickness and affect the use effect of metal powder, and achieves improved pulverization effect. , the effect of improving the preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

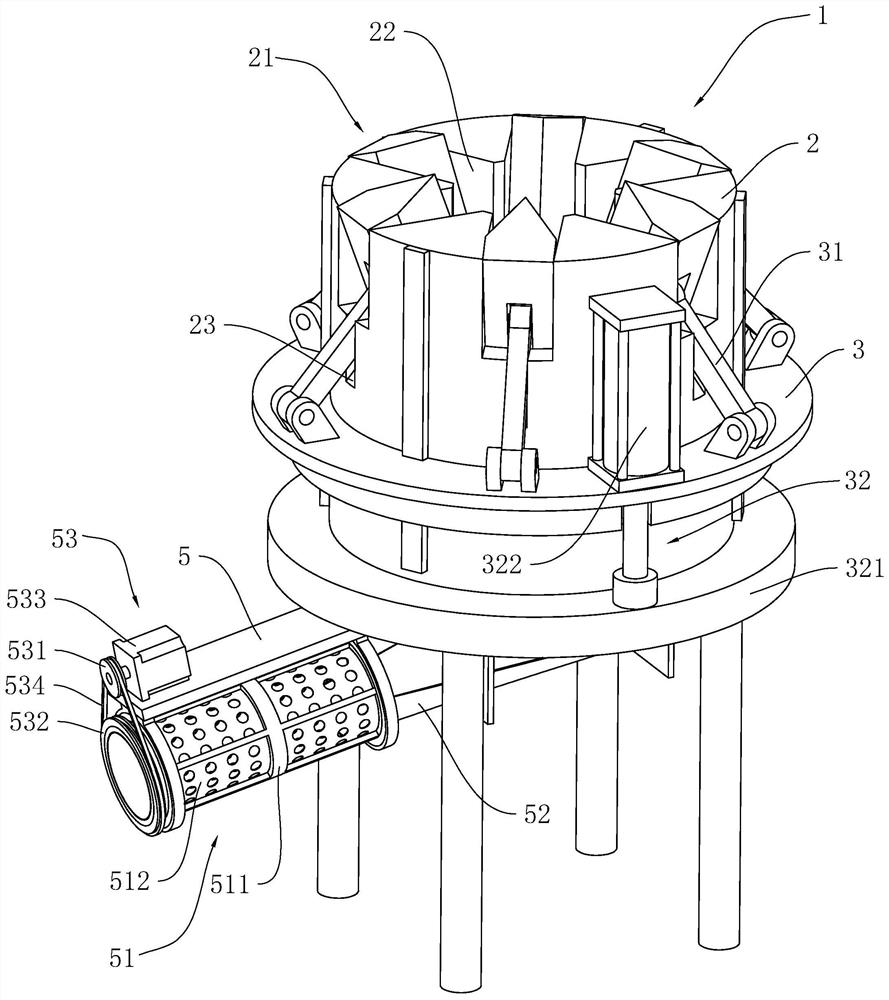

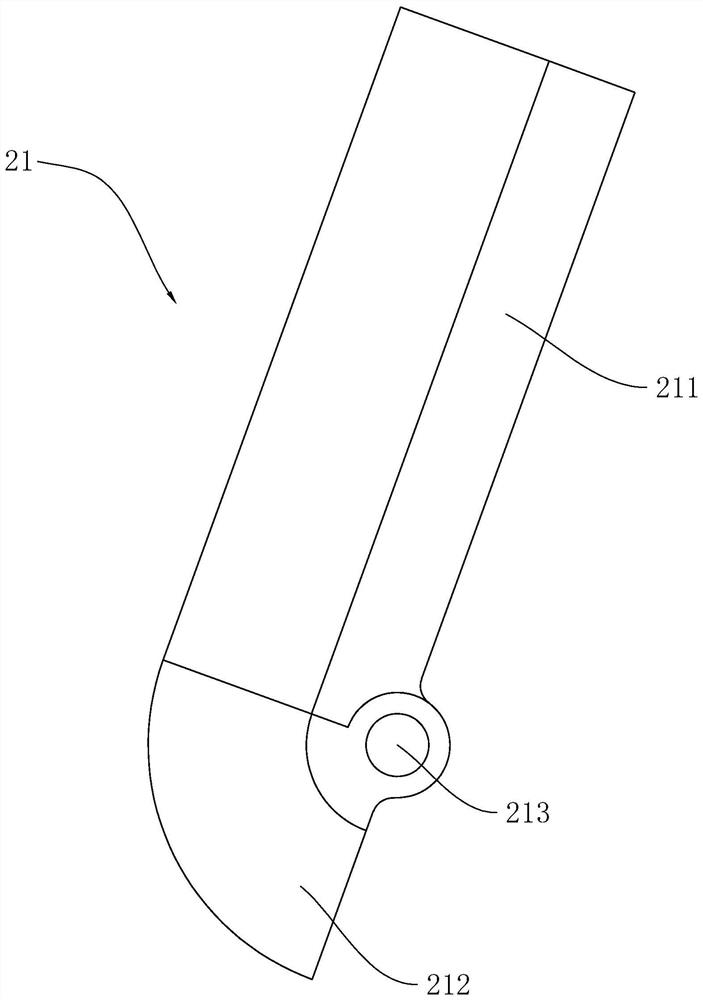

[0036] The following is attached Figure 1-5 The application is described in further detail.

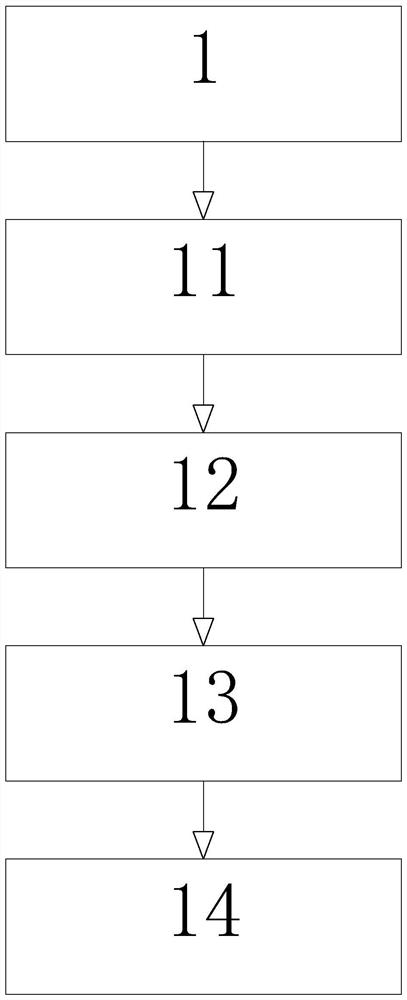

[0037] The embodiment of the present application discloses a process for processing high-carbon ferrochrome powder and a production line for processing high-carbon ferrochrome powder. like figure 1 , The processing technology of high carbon ferrochrome powder includes the following construction steps.

[0038] Crushing treatment of metal raw materials: the high-carbon ferrochrome raw materials are transported to the crusher 1 for crushing by means of belt 534 transmission or manual transportation, and the blocky high-carbon ferrochrome raw materials are crushed to reduce the volume of high-carbon ferrochrome raw materials .

[0039] Crushing treatment of metal raw materials: the crushed high-carbon ferrochrome raw materials are transported by the belt 534 or manually transported into the pulverizer 11, and the crushed high-carbon ferrochrome raw materials are further crushed to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com