Garbage treatment equipment for biodegradation

A waste treatment equipment and biodegradation technology, applied in the field of waste treatment equipment for biodegradation, can solve the problems of low solid-liquid separation efficiency, danger, waste of working time, etc., and achieve the effect of improving functionality and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

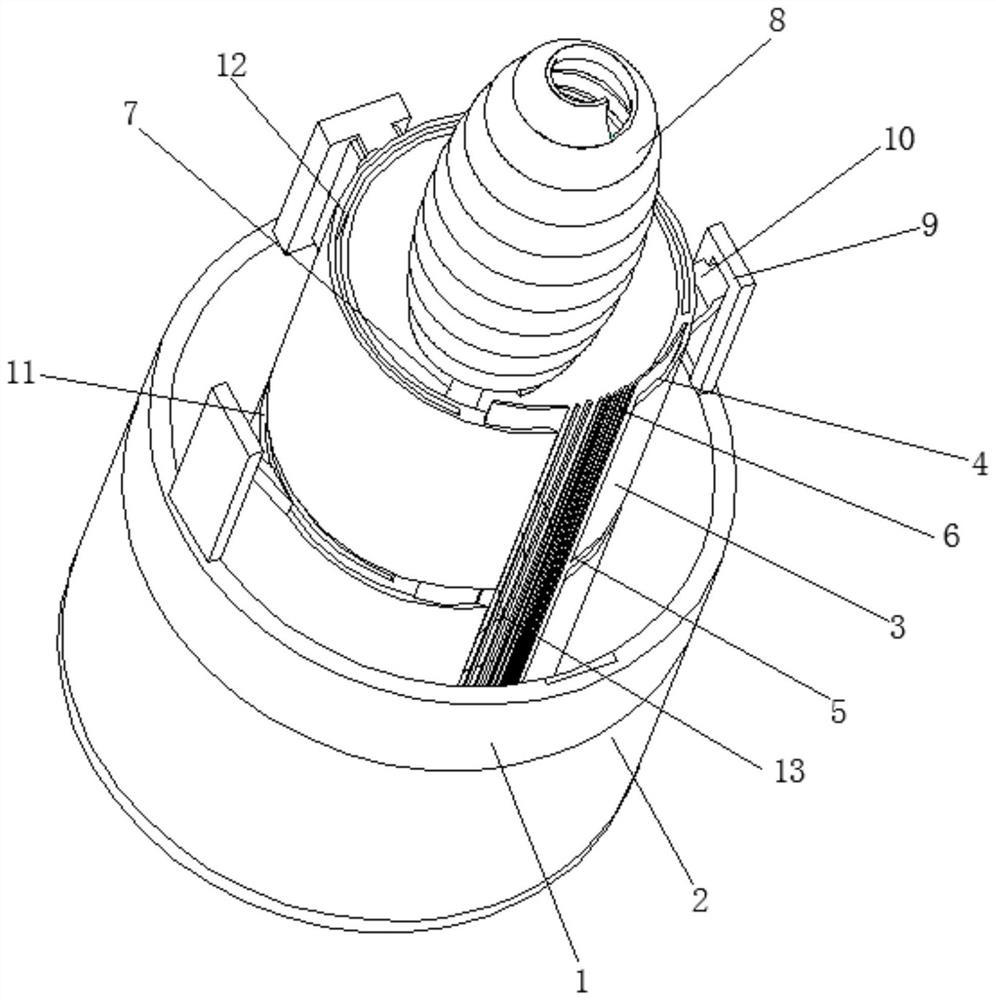

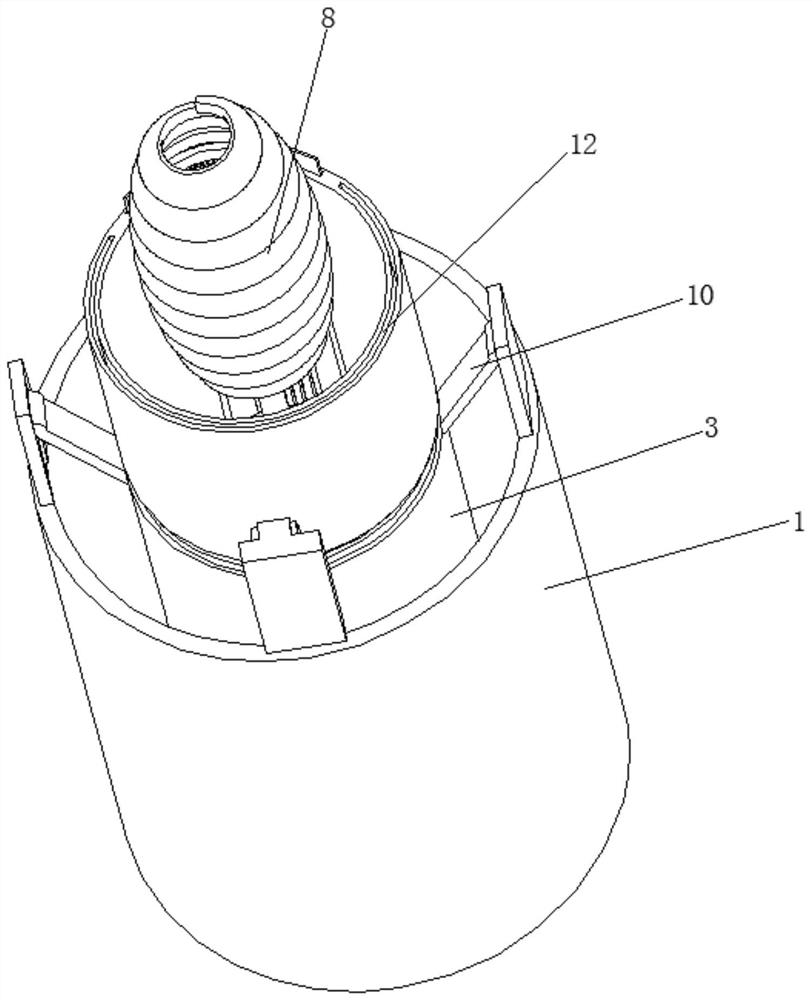

[0033] see Figure 1-3 , the present invention provides a technical solution: a biodegradable waste treatment equipment, comprising a recovery cylinder 1, the inner surface of the recovery cylinder 1 is provided with a relaxation mechanism 2, and the inner surface of the recovery cylinder 1 is slidingly connected to a collection cylinder 3, the collection cylinder The inner surface of 3 is provided with a through groove 4, the inner surface of the through groove 4 is slidably connected with a screening window 5, the inner surface of the screening window 5 is provided with a one-way mechanism 6, and the inner surface of the collection cylinder 3 is rotatably connected with a drive shaft 7, The outer surface of the drive shaft 7 is fixedly connected with a distinguishing mechanism 8, the top of the recovery cylinder 1 is uniformly fixedly connected with a fixed plate 9, the inner surface of the fixed plate 9 is connected with a steering rod 10 in rotation, and the outer surface o...

Embodiment 2

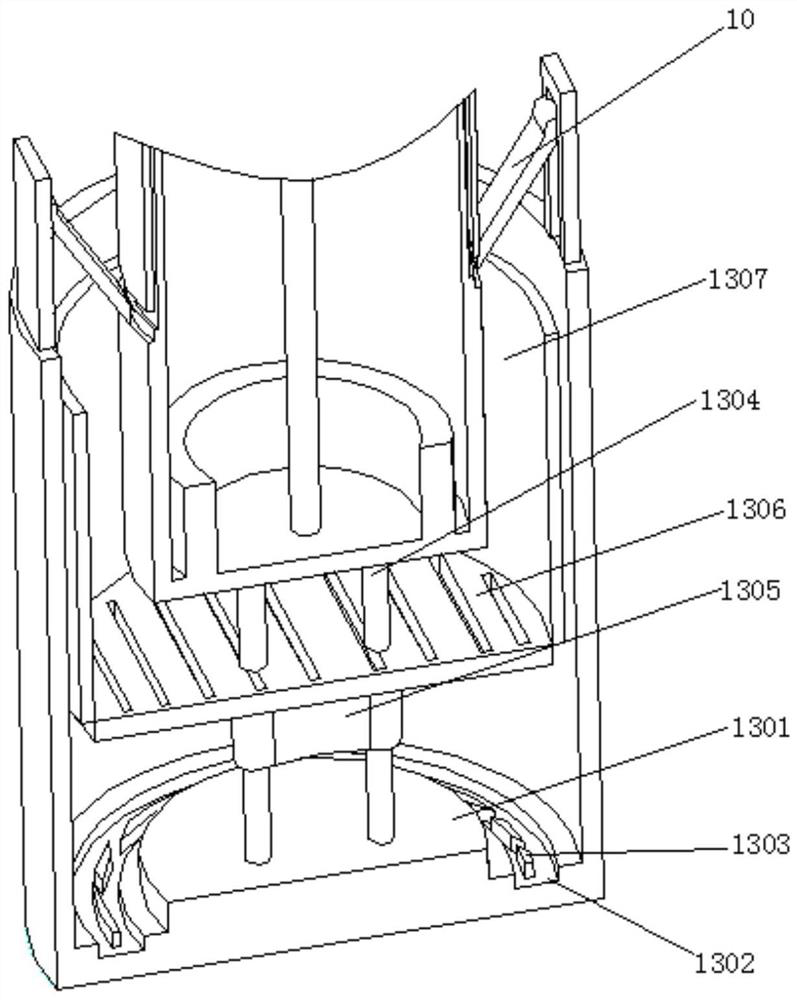

[0040] see Figure 4-5 , the present invention provides a technical solution: the distinguishing mechanism 8 includes a tapered threaded screen frame 801, and the top and bottom of the tapered threaded screen frame 801 are respectively fixedly connected to the upper and lower sides of the outer surface of the drive shaft 7.

[0041] The outer surface of the driving shaft 7 is sheathed with a thin thread 802 , the outer surface of the thin thread 802 is rotatably connected with the outer surface of the driving shaft 7 , and the inner surface of the groove 12 is movably connected with a protection component 803 . After the liquid enters the inside of the collection cylinder 3, the smaller garbage in the liquid can be thrown out, and the speed at which the liquid enters the collection cylinder 3 can be accelerated when the collection cylinder 3 rotates inside.

[0042] The protection component 803 includes a conical cover a1, the bottom of the conical cover a1 is movably connecte...

Embodiment 3

[0046] see Figure 6 The present invention provides a technical solution: the one-way mechanism 6 includes a connecting plate surface 601, and the outer surface of the connecting plate surface 601 is fixedly connected with the inner surface of the screening window 5.

[0047] The inner surface of the connecting plate surface 601 is connected with a curved baffle 602 through a rotating shaft, and the outer surface of the curved baffle 602 is fixedly connected with a sieve plate 603, and the inner surface of the connecting plate surface 601 is rotated under the curved baffle 602. A fixed column 604 is connected. The pressure generated by the squeezed liquid can flush away the curved baffle 602, and the curved baffle 602 that loses pressure after the water flow enters returns to its original position, preventing the garbage from entering the collection tube 3 and preventing the liquid from flowing back.

[0048] In the above-mentioned embodiment three:

[0049] Through the use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com