Preparation method for reducing content of nicotine in Yunnan tobacco extract refined substance

A technology of extract and Yunyan, which is applied in the field of preparation for reducing the nicotine content in the refined extract of Yunyan, and can solve the problems of affecting the quality of the refined extract of Yunyan, increasing the hazard of smoking, destroying active ingredients, etc., and achieving rich fragrance Diverse, reduced nicotine content, mellow and natural aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

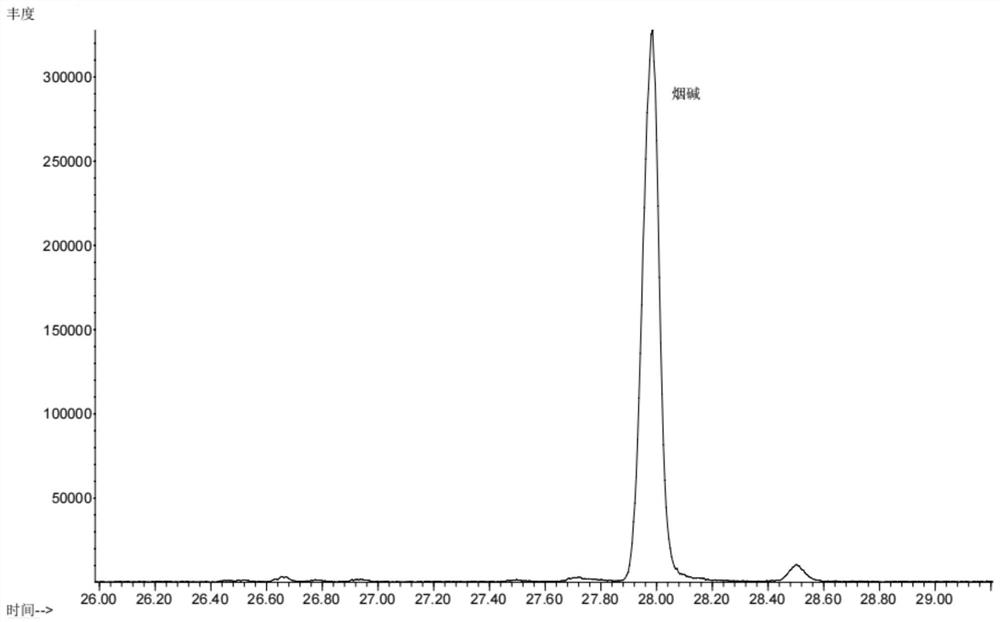

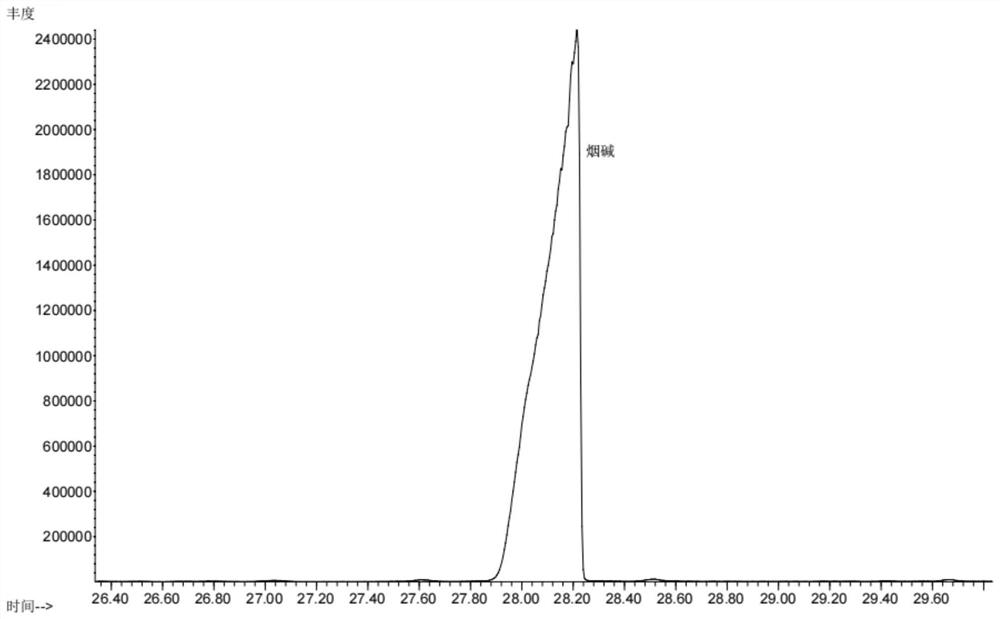

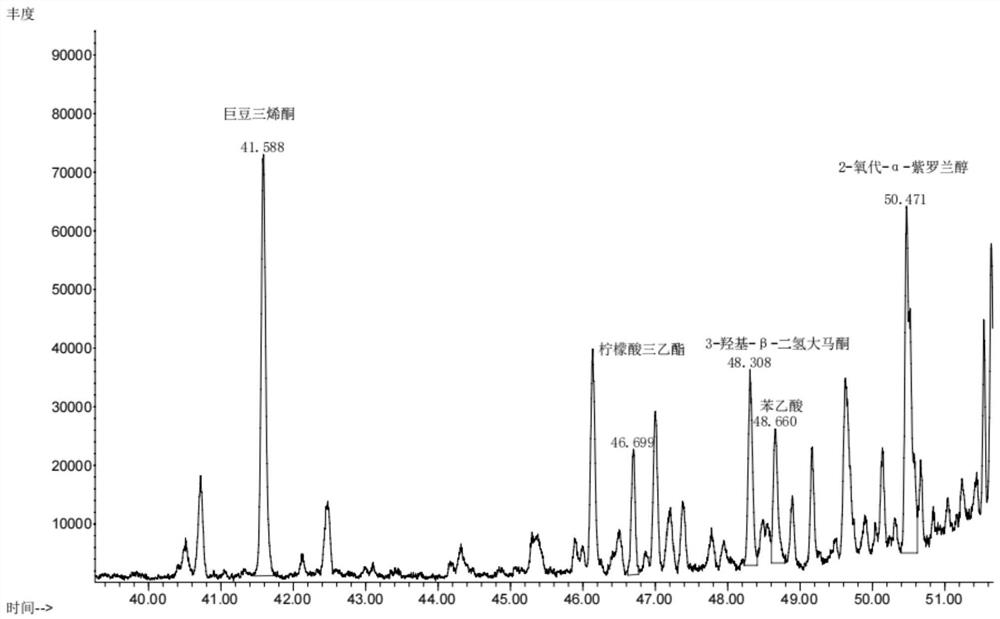

Image

Examples

Embodiment 1

[0034] A preparation method for reducing the nicotine content in refined Yunyan extract, comprising the following process steps:

[0035] a. Pretreatment: Weigh Yunyan extract as raw material, weigh deionized water and propylene glycol and mix them together as mixed solution A, the mass ratio of deionized water and propylene glycol is 100:40; mix Yunyan extract with mixed solution A, The mass ratio of Yunyan extract to mixed solution A is 100:200, then stir for 30 minutes at a stirring speed of 130 rpm, add deionized water to the stirred and dissolved material, add deionized water and Yunyan extract The mass ratio is 1:12;

[0036] B, shearing: the mixed material obtained in the previous step is sheared with a high-speed shearing machine, and the shearing time is 30 minutes;

[0037] c. Centrifugation: centrifuge the sheared material, the centrifuge speed is 6000 rpm, the centrifugation time is 30 minutes, and the supernatant is collected;

[0038] d, upper column adsorption...

Embodiment 2

[0043] A preparation method for reducing the nicotine content in refined Yunyan extract, comprising the following process steps:

[0044] a. Pretreatment: Weigh Yunyan extract as raw material, weigh deionized water and propylene glycol and mix them together as mixed solution A, the mass ratio of deionized water and propylene glycol is 100:60; mix Yunyan extract with mixed solution A, The mass ratio of Yunyan extract to mixed solution A is 100:300, then stir for 40 minutes at a stirring speed of 110 rpm, add deionized water to the stirred and dissolved material, add deionized water and Yunyan extract The mass ratio is 1:16;

[0045] B, shearing: the mixed material obtained in the previous step is sheared with a high-speed shearing machine, and the shearing time is 40 minutes;

[0046] c. Centrifugation: Centrifuge the sheared material, the centrifuge speed is 4000 rpm, the centrifugation time is 40 minutes, and the supernatant is collected;

[0047] d, upper column adsorption...

Embodiment 3

[0052] A preparation method for reducing the nicotine content in refined Yunyan extract, comprising the following process steps:

[0053] a. Pretreatment: Weigh Yunyan extract as raw material, weigh deionized water and propylene glycol and mix them as mixed solution A, the mass ratio of deionized water and propylene glycol is 100:52; mix Yunyan extract with mixed solution A, The mass ratio of Yunyan extract to mixed solution A is 100:270, then stir for 36 minutes at a stirring speed of 120 rpm, add deionized water to the stirred and dissolved material, add deionized water and Yunyan extract The mass ratio is 1:13;

[0054] B, shearing: the mixed material obtained in the previous step is sheared with a high-speed shearing machine, and the shearing time is 37 minutes;

[0055] c. Centrifugation: Centrifuge the sheared material, the centrifuge speed is 5500 rpm, the centrifugation time is 33 minutes, and the supernatant is collected;

[0056] d, upper column adsorption: the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com