Mineral composite cool uvioresistant fiber

An anti-ultraviolet and composite fiber technology, which is applied in the field of textiles, can solve the problems of affecting the effect of cooling fibers, disappearing, and reducing the cooling effect, and achieves the effects of convenient mixed processing and production, improved contact cold feeling, and good heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]This embodiment discloses a mineral composite cool anti-ultraviolet fiber, including mutually twisted bamboo pulp fibers, cellulose fibers, anti-ultraviolet fibers and mineral cool-feeling composite fibers, and the mineral cool-feeling composite fibers are processed from cool-feeling masterbatches ;Cool feeling masterbatch includes base material, graphene material and compound mineral modifier, base material can choose masterbatch material according to fiber strength requirement, for example can choose PET material as the basis; After graphene and compound mineral additive are mixed into fiber, then Twisting it with bamboo pulp fiber, cellulose fiber, and anti-ultraviolet fiber can improve the cold feeling of the fiber fabric, good heat conduction and moisture conduction performance, can keep the human skin comfortable, and has the performance of a cool fabric and certain UV protection effect.

[0041] Graphene material can adopt graphene or graphene oxide, also can adop...

Embodiment 2

[0044] This embodiment discloses a mineral composite cool anti-ultraviolet fiber, and on the basis of the first embodiment, the preparation method of the cool-feeling masterbatch is described;

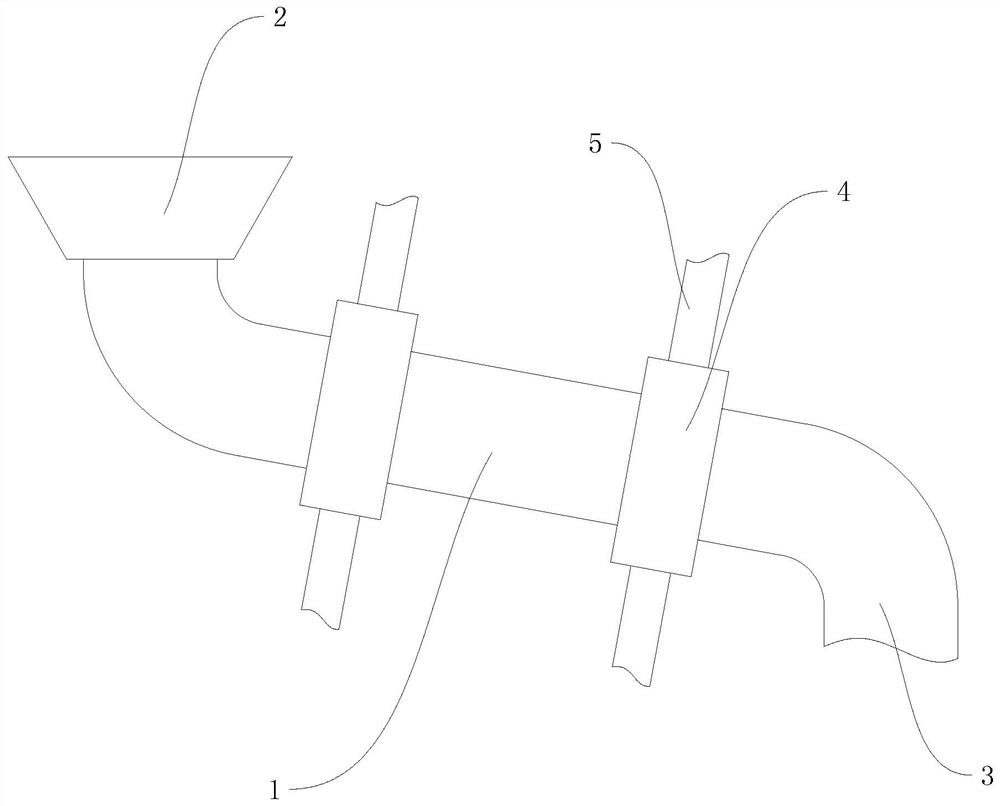

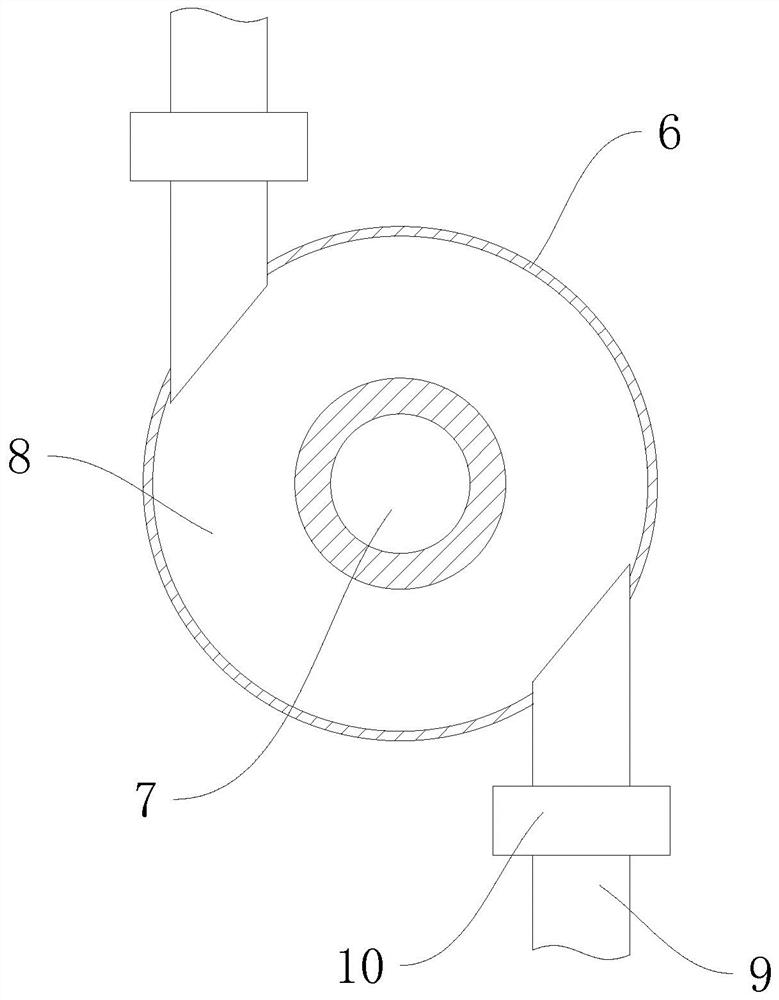

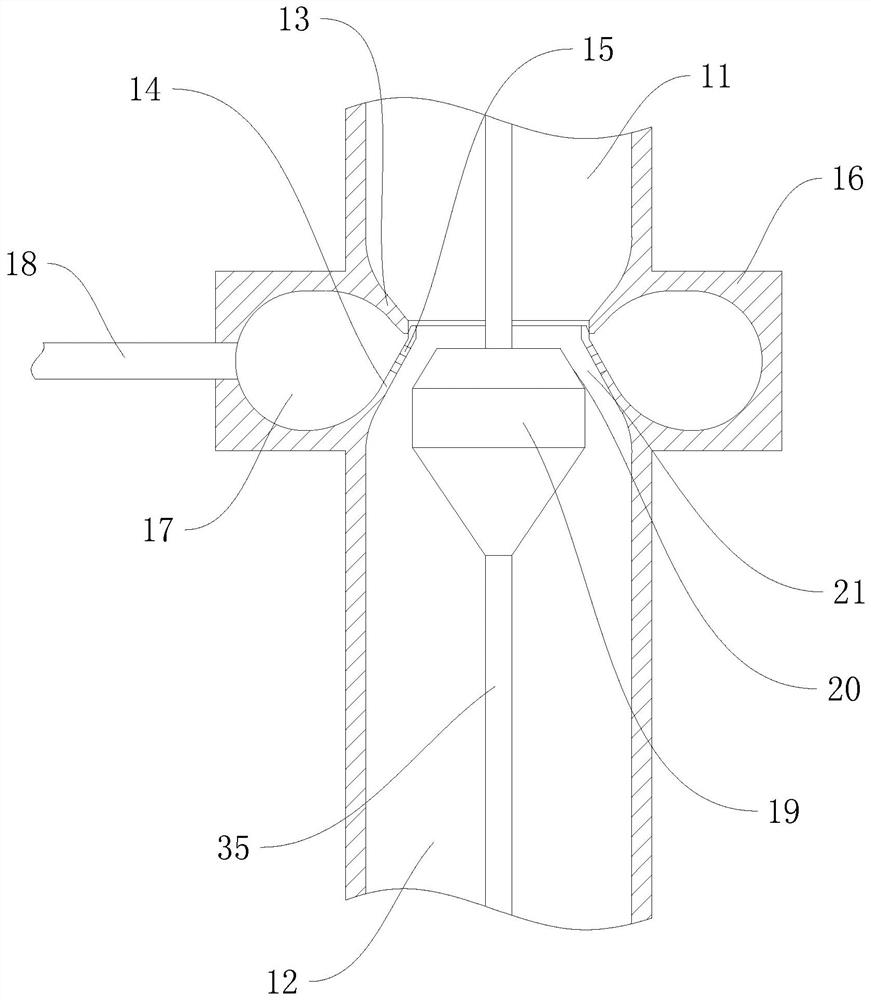

[0045] The preparation steps of the cool-feeling masterbatch include: first mixing the graphene material and the composite mineral modifier; and then compounding the graphene material and the composite mineral modifier through a mixing system to form a coating layer outside the masterbatch base material to obtain cool masterbatch;

[0046] Subsequent addition of graphene materials and composite mineral modified materials can modify the type of substrate, which is convenient for manufacturers to improve and optimize materials; in the production process, only the basic type of masterbatch substrate needs to be selected, and then Among them, graphene materials and composite mineral modifier materials are added in a schematic proportion, and processed to form a cooling masterbatch, which c...

Embodiment 3

[0049] This embodiment discloses a mineral composite cool anti-ultraviolet fiber. On the basis of Example 2, the preparation method of the cooling masterbatch is improved. The difference is that the graphene material and the composite mineral in the cooling masterbatch are modified The active agent is added in two parts;

[0050] In the preparation step of the cooling masterbatch, a part of the graphene material and the composite mineral modifier can be mixed first, and 35-55% of the graphene material and 20-50% of the composite mineral modifier can be used, and the mixed mixture will be put into Among the substrates, the substrate is then processed to form a masterbatch substrate; then the remaining graphene material and the composite mineral modifier are mixed, and the remaining graphene material and the composite mineral modifier are compounded through the mixing system A coating layer is formed outside the base material of the masterbatch to obtain a cool feeling masterbat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com