Novel anti-impact stand column

An anti-collision column and column technology, applied in the directions of pillars/supports, mining equipment, earthwork drilling, etc., can solve the problems of high manufacturing cost, long operation cycle, hydraulic column bending under compression, etc., to make up for the lack of impact resistance, The effect of restoring production quickly and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

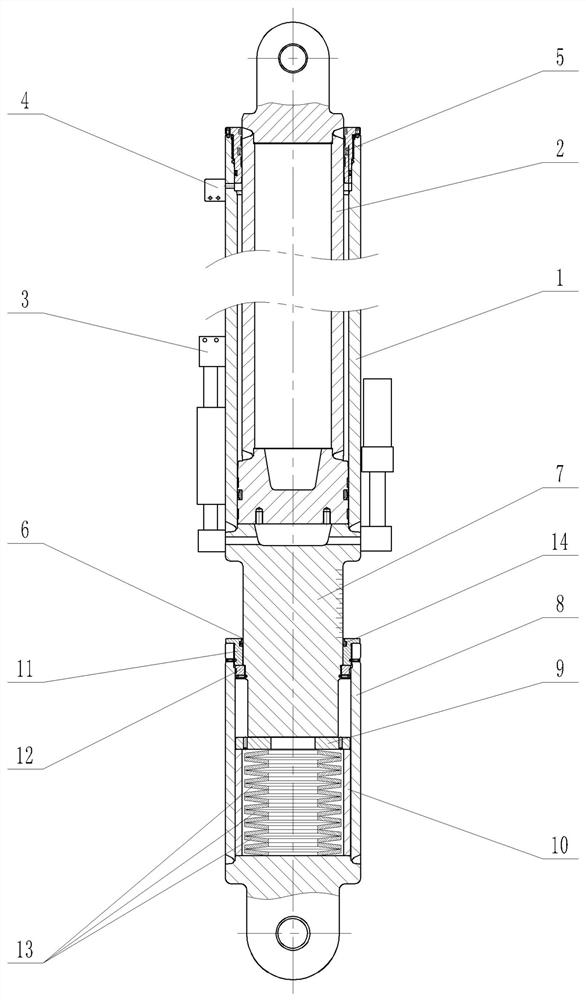

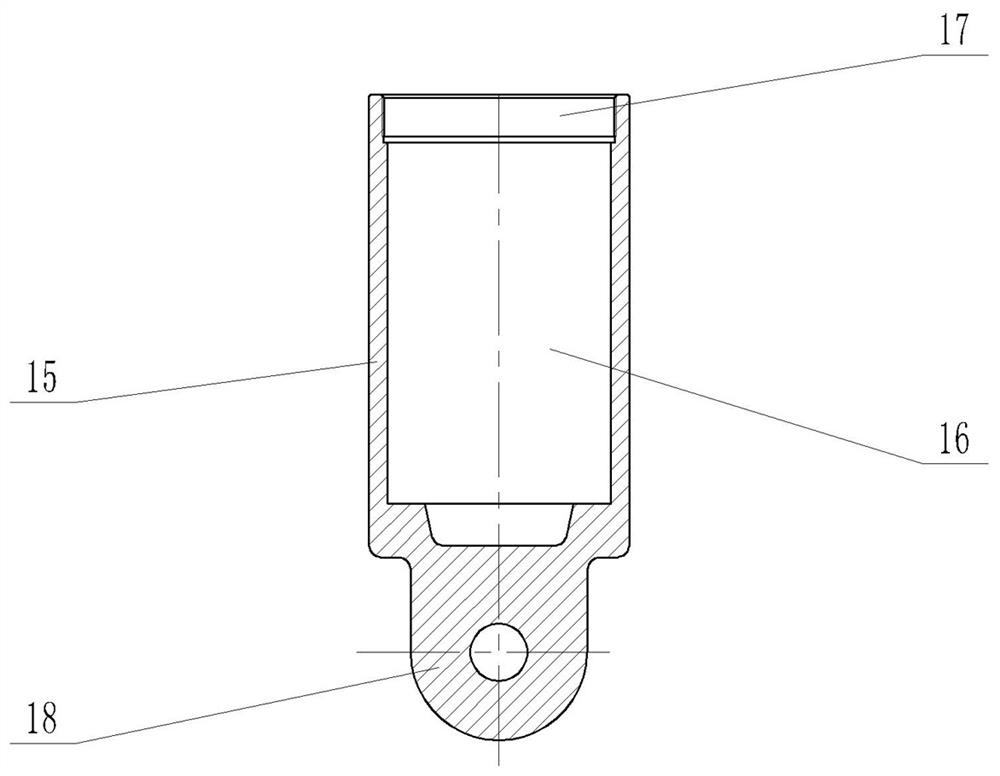

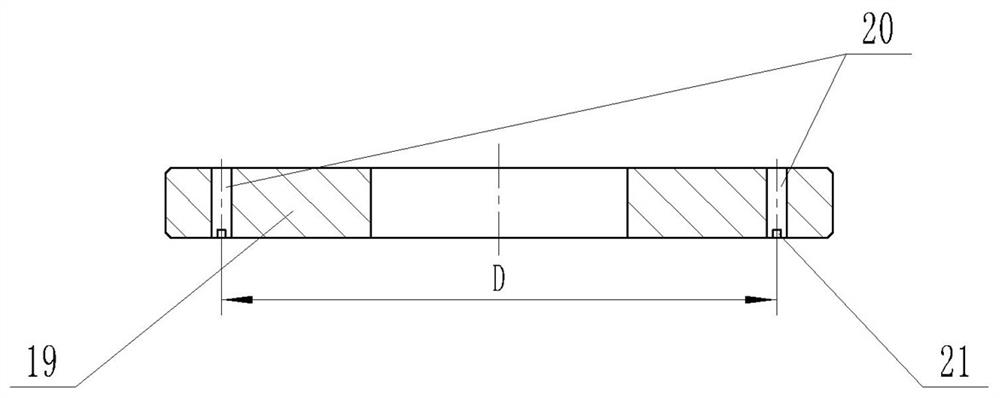

[0026] according to Figure 1-9The specific structure of the present invention will be described in detail. The new anti-shock column includes a column cylinder 1, and the upper opening of the column cylinder 1 is plugged with a vertically arranged telescopic live column 2. According to specific use requirements, the telescopic live column 2 can be single-stage telescopic or multi-stage Telescopic structure. The lower end of the column cylinder 1 is provided with a liquid inlet 3, the upper end of the column cylinder 1 is provided with a liquid return port 4, and the lower end of the column cylinder 1 is also provided with a pressure relief safety valve; The lower end surface of the piston of 2 or the promotion of the upper end surface of the piston drive the telescopic live column 2 to stretch out or retract, and form the support to the telescopic live post 2 through the liquid medium inside the column cylinder 1. Simultaneously, between the inner wall of the upper end open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com