Furnace top expansion device

An expansion device and expansion plate technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as cracking of the top outer guard plate, achieve good overall shape, release deformation, and reduce unfavorable factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

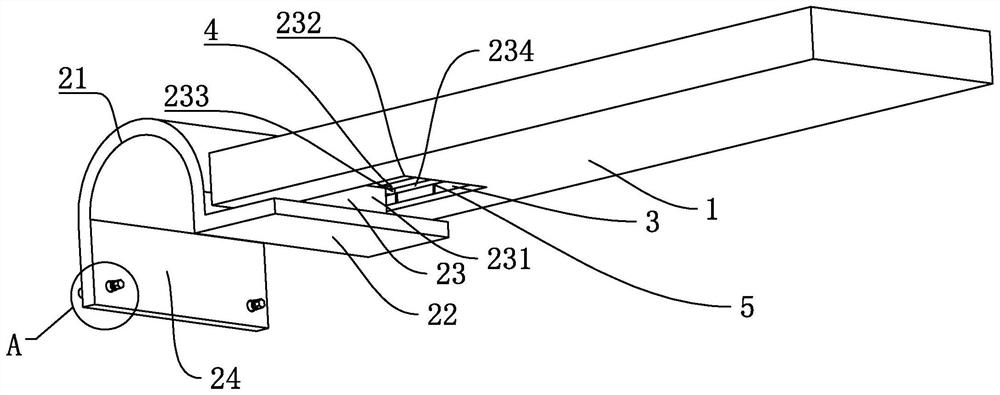

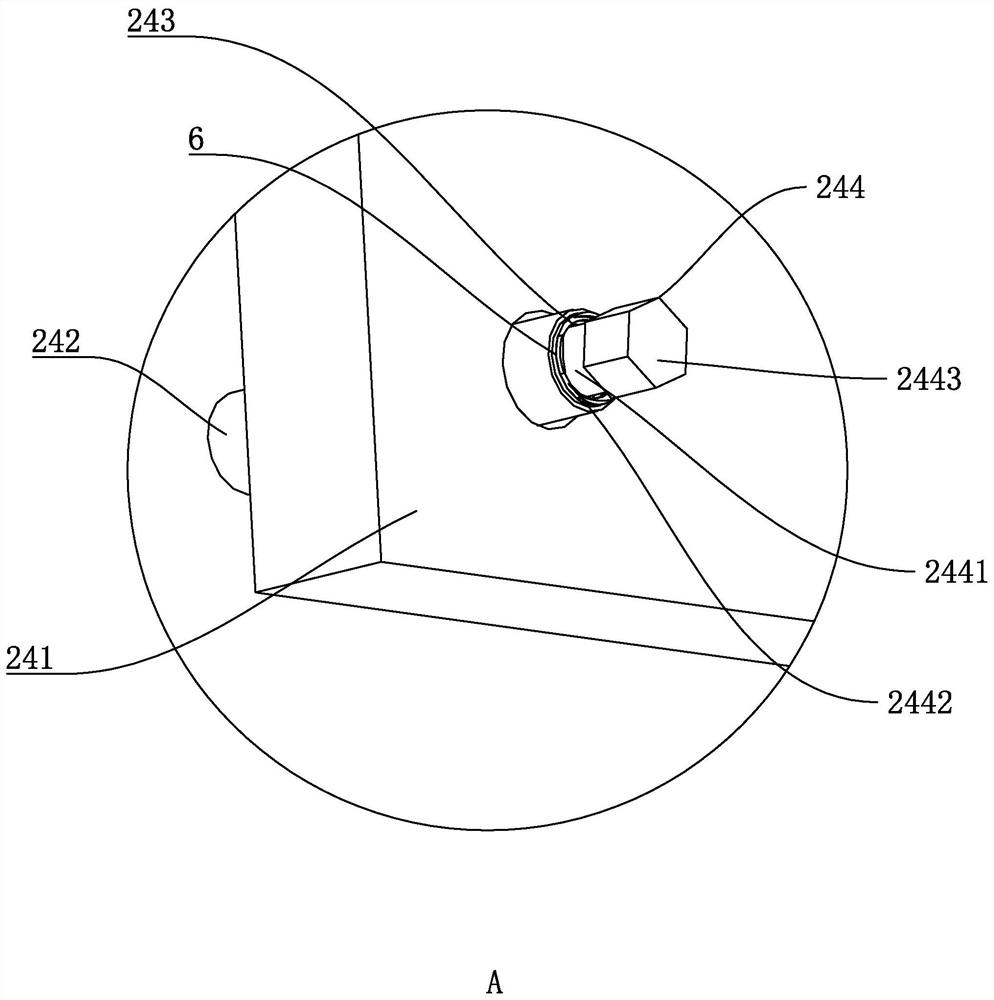

[0027] The technical scheme adopted in the present invention is: a furnace top expansion device, such as figure 1 and figure 2 As shown, it includes a rectangular straight plate 1, and the rectangular straight plate 1 is also provided with an anti-expansion device 2. The anti-expansion device 2 includes flexible expansion plates 21 located on both sides of the rectangular straight plate 1, and a connecting plate 22 is provided at the bottom of the flexible expansion plate 21, and The connecting plate 22 is provided with a connecting device 23 between the rectangular straight plate 1, and the flexible expansion plate 21 is bent and presents an inverted U shape. One end of the bottom of the flexible expanding plate 21 is welded to the connecting device 23, and the other end is also A fixing device 24 is provided, and the connecting device 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com