Diaphragm and laser

A technology of lasers and apertures, applied in optics, instruments, optical components, etc., can solve problems such as the impact of optical system performance, affecting equipment performance, etc., to avoid half-wave loss, prevent energy concentration, and reduce the impact of service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

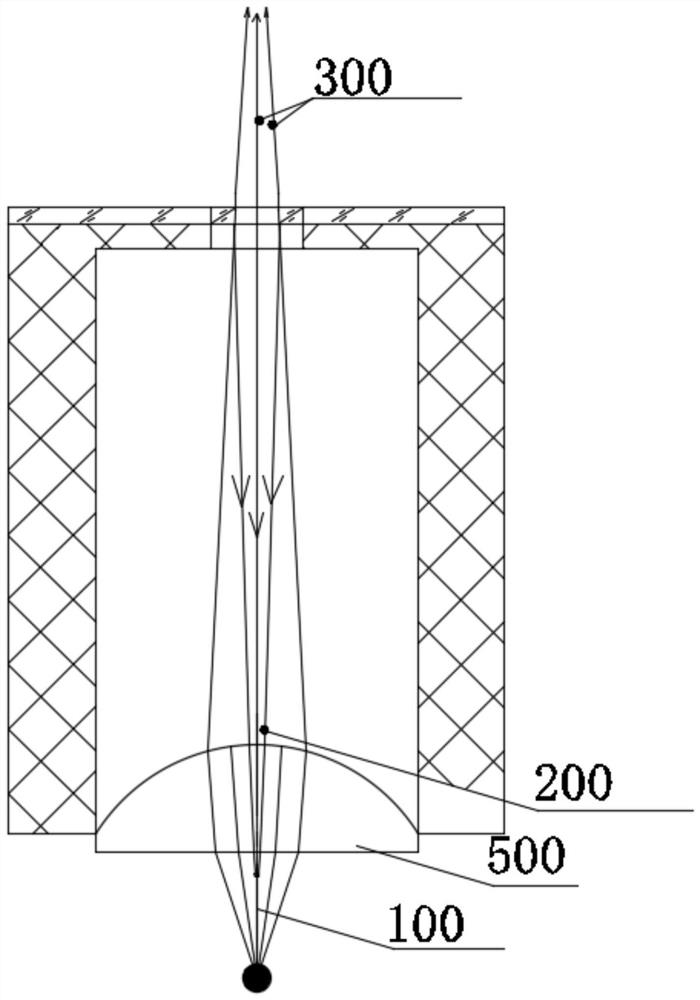

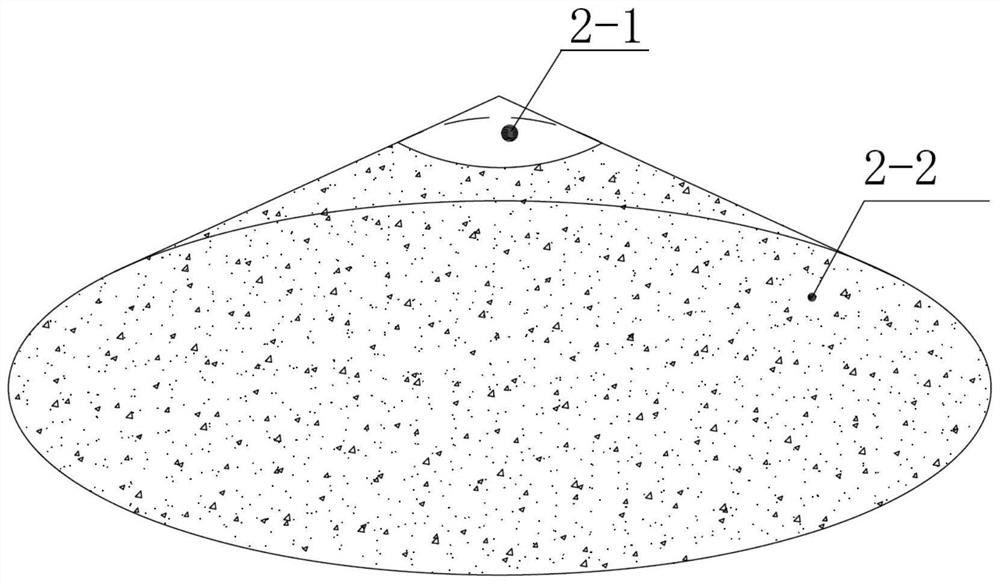

[0025] The "principal optical axis" in this application document refers to the straight line passing through the centers of the two spherical surfaces of the thin lens in geometric optics; Part of the beam; "aperture hole" should be understood as the optical space (shape) that constrains the light emitted from optical elements such as lenses or light sources to this "aperture hole" to obtain the beam we need for parts processing and other operations , it can be an unfilled through hole, or a light-transmitting hole filled with a transparent material. The shape of the hole can be a circle or other polygons, such as a hexagon. Other words, words, and sentences in this application document, unless otherwise specified, if they are professional terms in the field of optics, can be understood according to the meanings specified in the industry terms. Usually the meaning is understood.

[0026] In the prior art, since the diaphragm is often located at the end of the optical system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com