Visual detection method for blanking of winding machine

A visual inspection and winding machine technology, applied in the field of image processing, can solve problems such as backward industrial needs and narrow measurement range, and achieve the effect of solving versatility, reducing data volume, and facilitating extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

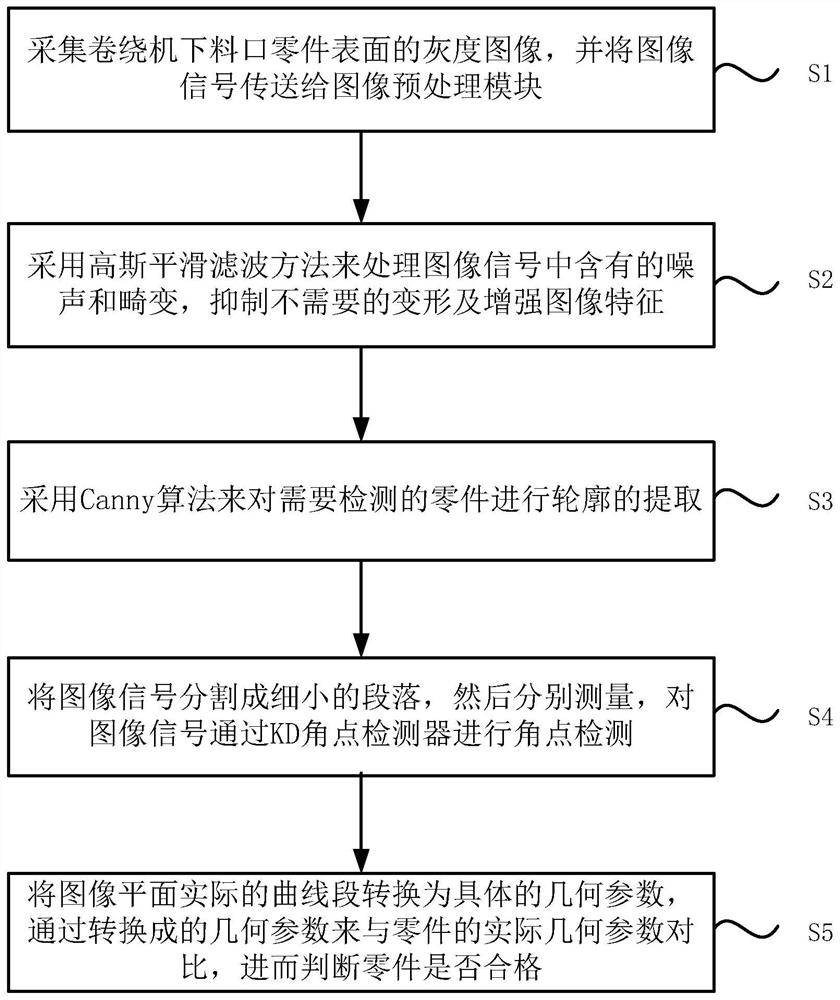

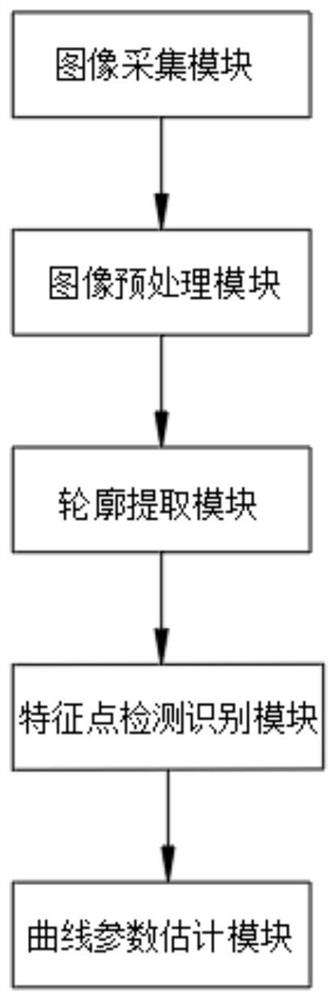

[0029] Please refer to figure 1 and 2 , an embodiment of the present invention provides a visual inspection method for unloading of a winding machine, comprising the following steps:

[0030] Step S1, image acquisition module: collect the grayscale image of the surface of the part at the discharge port of the winding machine, and transmit the image signal to the image preprocessing module;

[0031] Step S2, image preprocessing module: use Gaussian smoothing filtering method to process noise and distortion contained in the image signal, suppress unnecessary deformation and enhance image features;

[0032] Step S3, contour extraction module: use the Canny algorithm to extract the contour of the part to be detected;

[0033] Step S4, feature point detection and recognition module: segment the image signal into small segments, then measure them separately, and perform corner detection on the image signal through the KD corner detector;

[0034] Step S5, curve parameter estimati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com