Substation circuit breaker electric heat tracing system working state monitoring method and system

A working state, substation technology, applied in the field of substations, can solve problems such as affecting the normal operation of the power system, increasing the difficulty of operation and maintenance, and high work intensity, achieving digital information collection, reducing the degree of manual participation, and improving safety and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 of the present disclosure introduces a method for monitoring the working state of an electric heat tracing system of a circuit breaker in a substation.

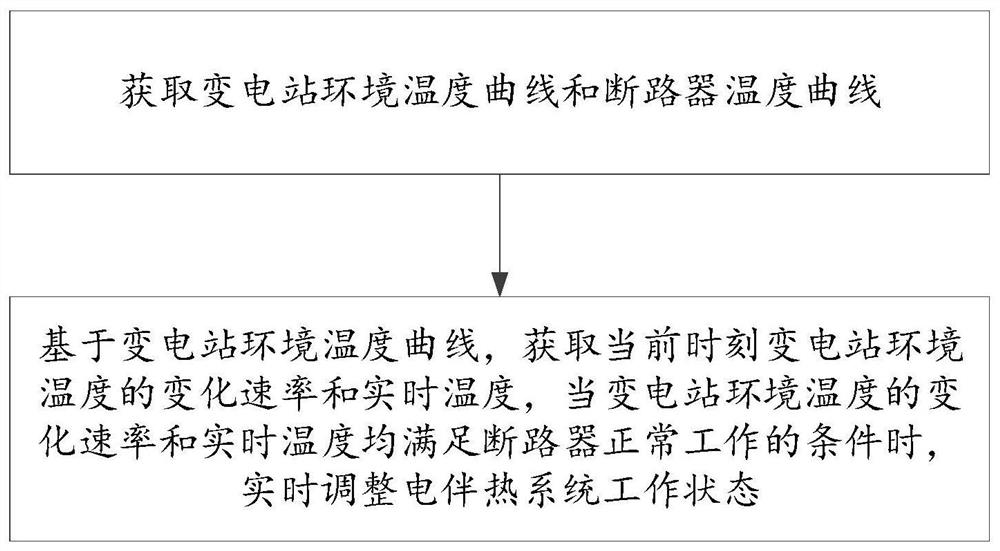

[0041] Such as figure 1 A method for monitoring the working state of a substation circuit breaker electric heat tracing system includes the following steps:

[0042] Obtain the ambient temperature curve of the substation and the temperature curve of the circuit breaker;

[0043] Based on the ambient temperature curve of the substation, the change rate and real-time temperature of the ambient temperature of the substation are obtained at the current moment;

[0044] When the change rate and real-time temperature of the ambient temperature of the substation meet the conditions for the normal operation of the circuit breaker, adjust the working status of the electric heat tracing system in real time, and obtain the change rate and real-time temperature of the circuit breaker temperature at the current moment...

Embodiment approach

[0050] As one or more implementations, the change rate and real-time temperature of the ambient temperature of the substation when the circuit breaker is in normal operation are initially set as required.

[0051] In this embodiment, a tank-type SF6 circuit breaker that works above -20°C is used.

[0052]The opening and closing parameters of the electric heat tracing system include slope intervals K1, K2, K3, K4, ..., Kn and temperature values C1, C2, C3, C4, ..., Cn corresponding to the slope intervals. The setting of the initial parameters is based on the safe working temperature of the circuit breaker, the power and efficiency of the electric heating cable, and the thermal insulation of the site.

[0053] The external ambient temperature changes from -8°C to -25°C on the day, and at 18:03:25 at night, the monitoring system monitors that the real-time slope of the tangent curve of the ambient temperature is -2.18, and the real-time temperature is -13°C. Among them, the slo...

Embodiment 2

[0058] Embodiment 2 of the present disclosure introduces a system for monitoring the working state of the electric heat tracing system of a circuit breaker in a substation, and adopts the method for monitoring the working state of the electric heat tracing system of a circuit breaker in a substation introduced in Embodiment 1.

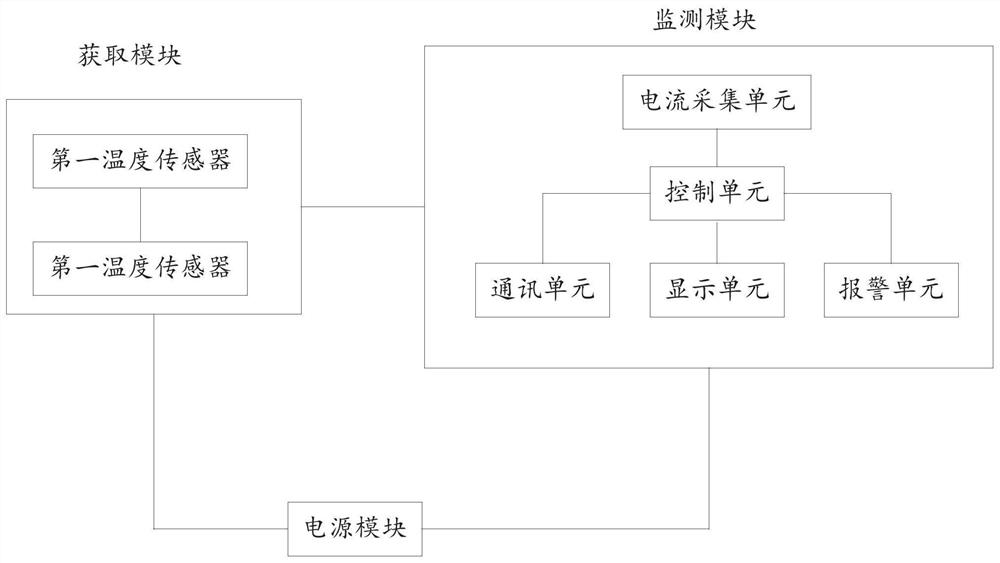

[0059] Such as figure 2 A substation circuit breaker electric heat tracing system working state monitoring system shown includes:

[0060] The acquisition module is configured to acquire the substation ambient temperature curve and the circuit breaker temperature curve;

[0061] The monitoring module is configured to obtain the change rate and real-time temperature of the substation ambient temperature at the current moment based on the substation ambient temperature curve, and adjust the electric heat tracing in real time when the change rate and real-time temperature of the substation ambient temperature meet the conditions for the normal operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com