System and method for exposing material with images

An image-to-image technology, which is applied in the direction of microlithography exposure equipment, photolithography exposure device, pattern surface photographic process, etc., can solve the problems of reducing brightness uniformity difference, etc. effect of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

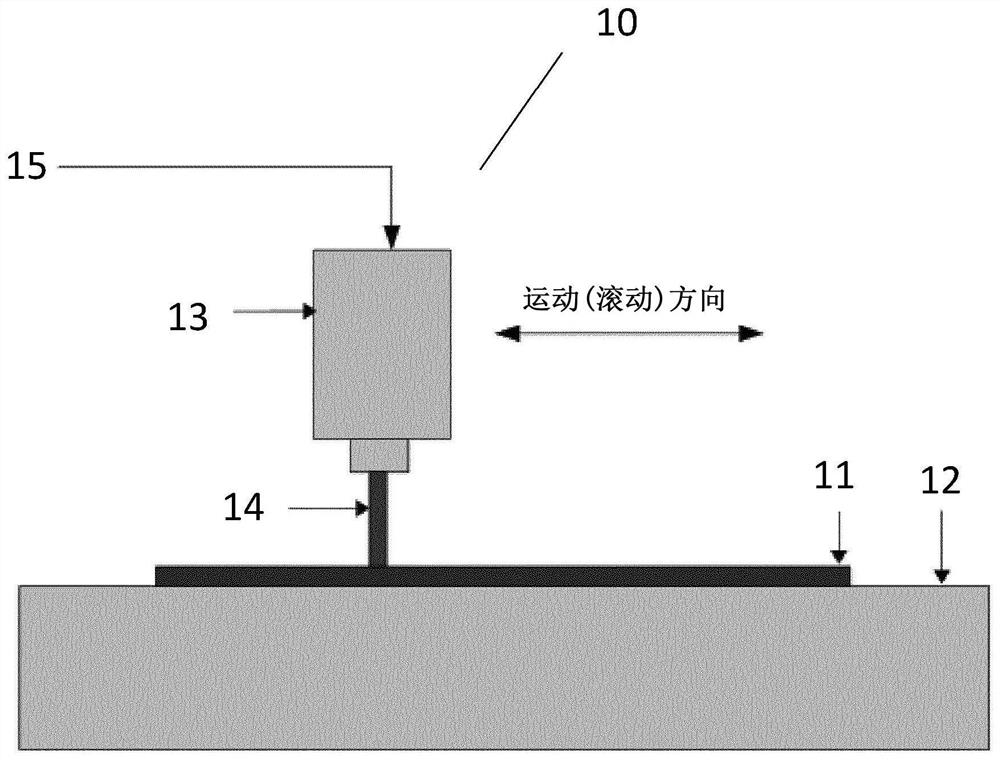

[0038] exist figure 1 In , a system 10 for exposing photosensitive or photopolymerizable material 11 layer by layer to build 3D objects or for 2D direct imaging lithography is shown.

[0039] The system includes an exposure table 12 and an electron light projector 13 arranged above the exposure table 12 . The electro-optical projector 13 may emit light 14 towards the exposure station 12, and thus onto any medium 11 arranged on the exposure station 12, thereby projecting an image onto the medium. For example, medium 11 is a photosensitive or photopolymerizable material. The electronic light projector 13 is moved relative to the exposure material 11 while a synchronization signal 15 is provided by the motor controller to enable the light projector to set the next image in the sequence of images.

[0040] This electronic light projector includes spatial modulators, such as DLP / LCD / LCOS or similar light / power projectors, used in 3D printers / rapid manufacturing machines or 2D lit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com