Bidirectional material taking device, using method and application

A technology of a reclaiming device and a pushing device is applied in the field of steel rolling in the metallurgical industry, which can solve the problem of scrap steel entering the electric furnace for steelmaking, and achieve the effects of energy saving, compact action and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

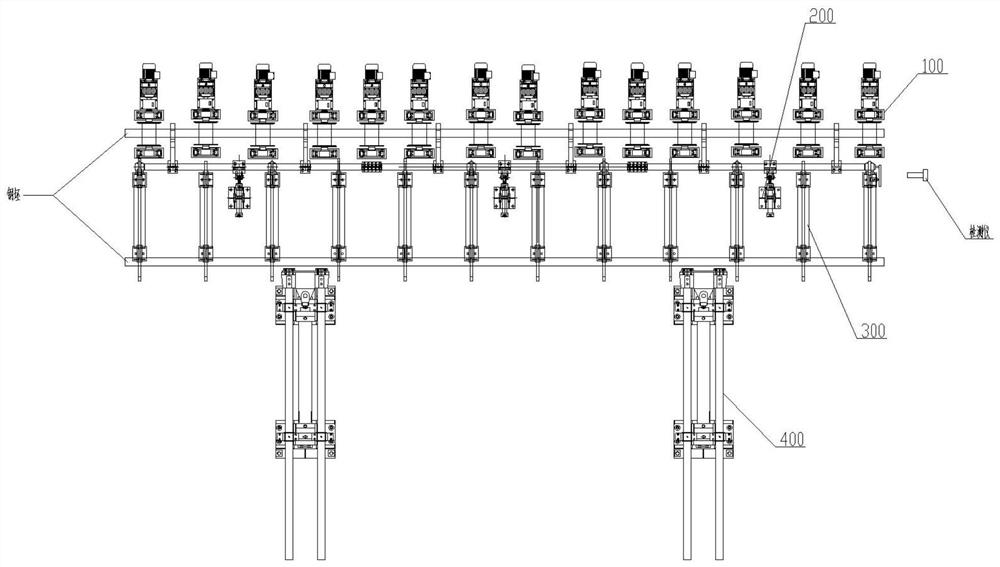

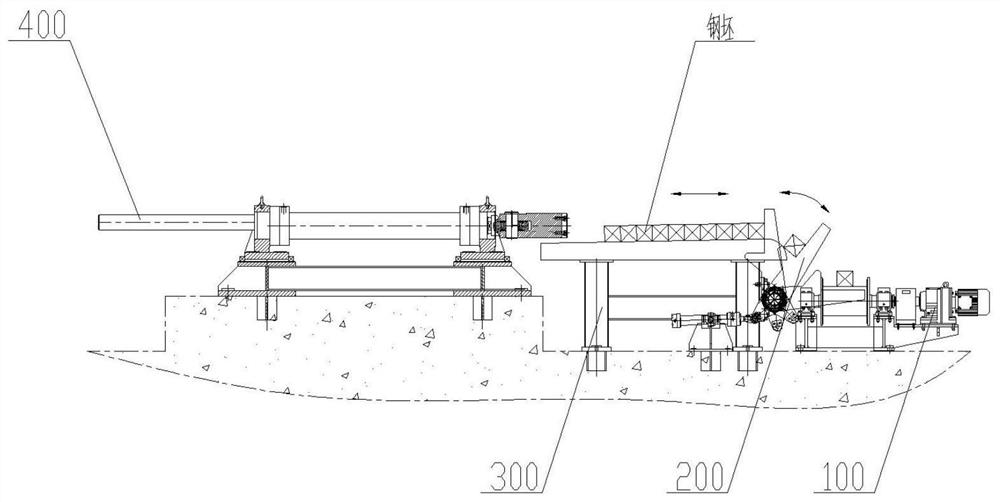

[0031] Such as figure 1 and figure 2 As shown, a two-way reclaiming device includes a collection stand 300 arranged on one side of the conveying roller table 100, and a steel shifting machine 200 is arranged below the collection stand 300, and a steel shifting fork 202 is movable installed for making the The material moves between the end of the collecting platform 300 close to the conveying roller table 100 and the conveying roller table 100; the side of the collecting platform 300 away from the conveying roller table 100 is also provided with a pusher 400, which is provided with a pushing device for The material on the collection stand 300 is pushed onto the steel fork 202 .

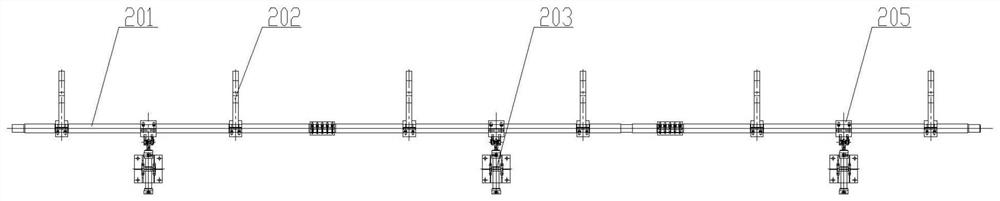

[0032] Such as image 3 and Figure 4As shown, in a preferred embodiment, the steel shifting machine 200 includes a first transmission shaft 201, a steel shifting fork 202, a first hydraulic cylinder device 203, a first bearing seat 204, a swing rod 205 and a first support 206; the first bearing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com