Gas stripping internal circulation membrane tank

A technology of internal circulation and membrane tank, which is applied in the direction of special treatment targets, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of large footprint and high treatment cost, and achieve small footprint, Improve the B/C ratio and the effect of better structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

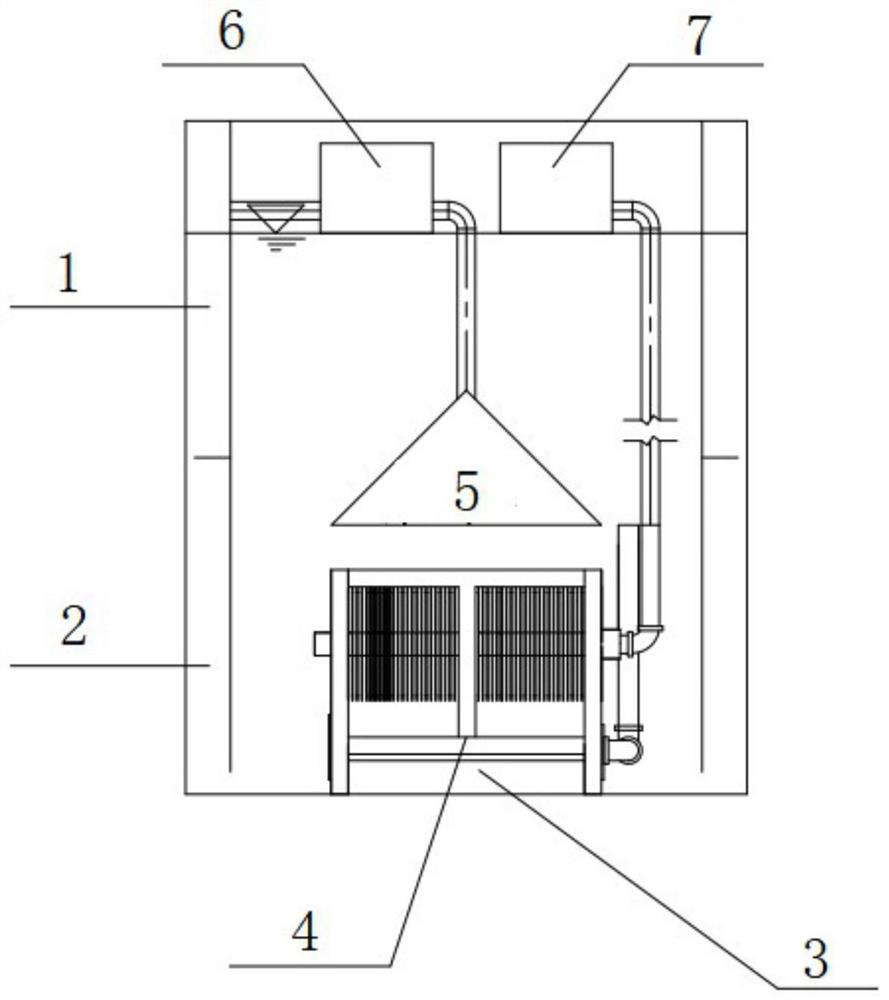

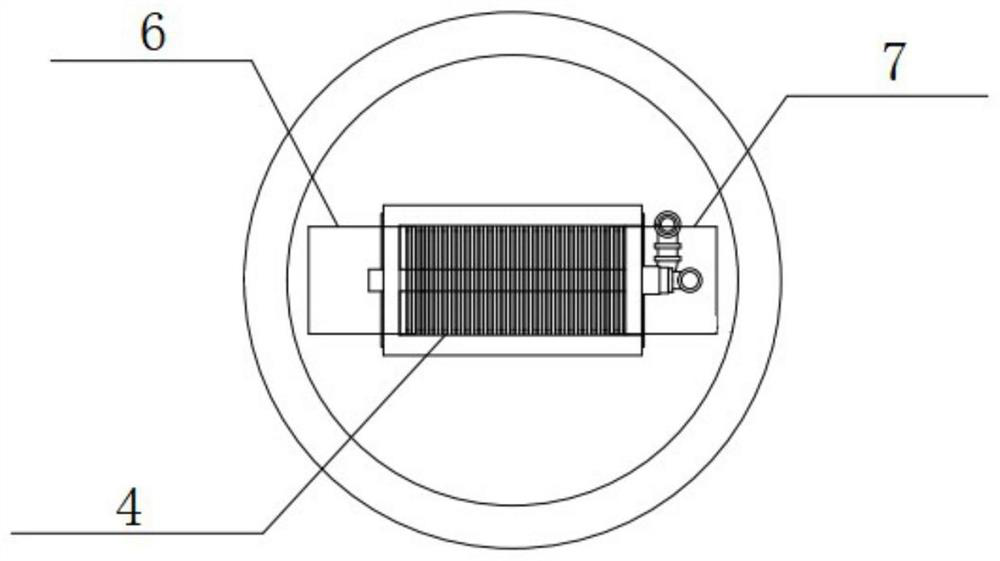

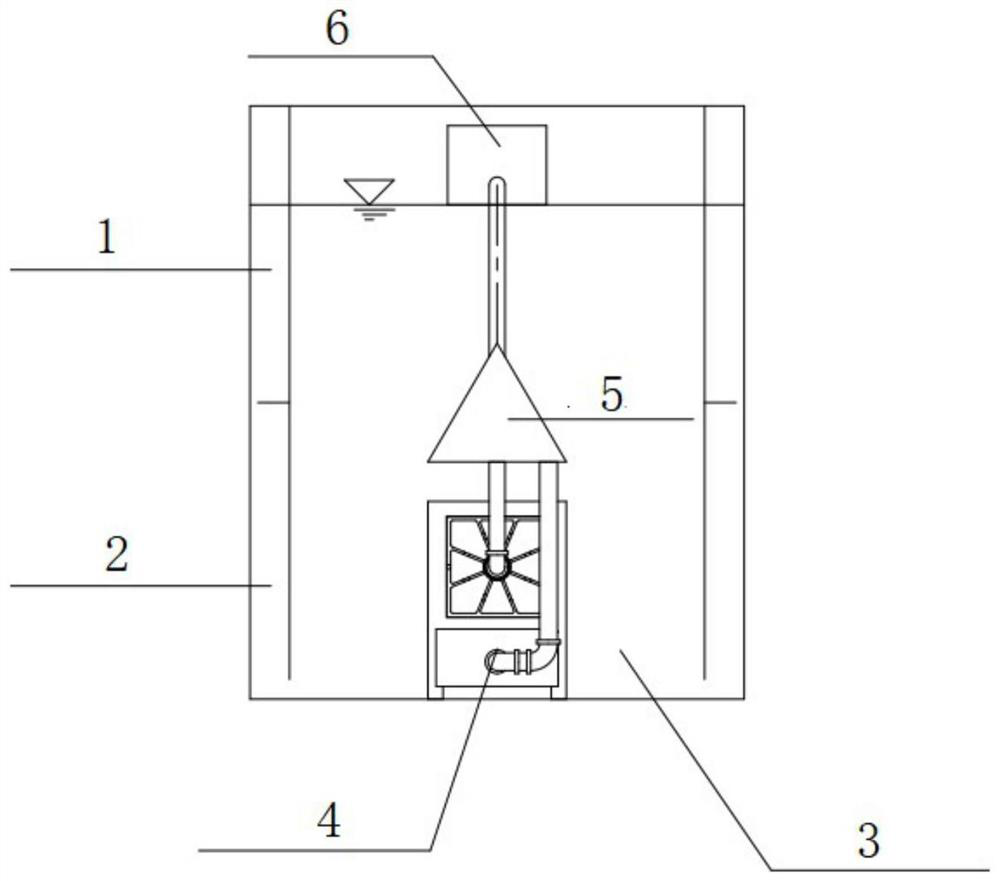

[0035] This embodiment provides an air lift internal circulation membrane tank, combined with A 2 / O-MBR film process or its improved process, etc., its structure is as follows figure 1 , 2 As shown in , 3, a circular tank is used as the reactor, and the inner and outer cylinders are set. The inner cylinder is an aerobic unit 3, the outer cylinder is an anaerobic unit 1 and anoxic unit 2, and the inner cylinder is placed with an MBR membrane stack 4, and the membrane stack A gas collection hood 5 is installed on the top surface, and a backwash water tank 7 and an air lift return water tank 6 are installed above the gas collection hood 5. The MBR membrane stack 4 sucks the water out into the backwash water tank 7 through the negative pressure of the suction pump, and the gas collection hood 5 collects the MBR membrane. Stack 4 scours a large amount of air for aeration, and uses the principle of air lift (the density difference of air-water mixture) to lift the nitrifying liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com