Microorganism sterilization and inoculation device

A technology of sterilization inoculation and microorganisms, applied in the direction of supporting/immobilizing microorganisms, sterilization methods, biochemical equipment and methods, etc., can solve the problems of long inoculation time, economic loss, and bacterial contamination, and achieve the prevention of bacterial strains Effect of infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

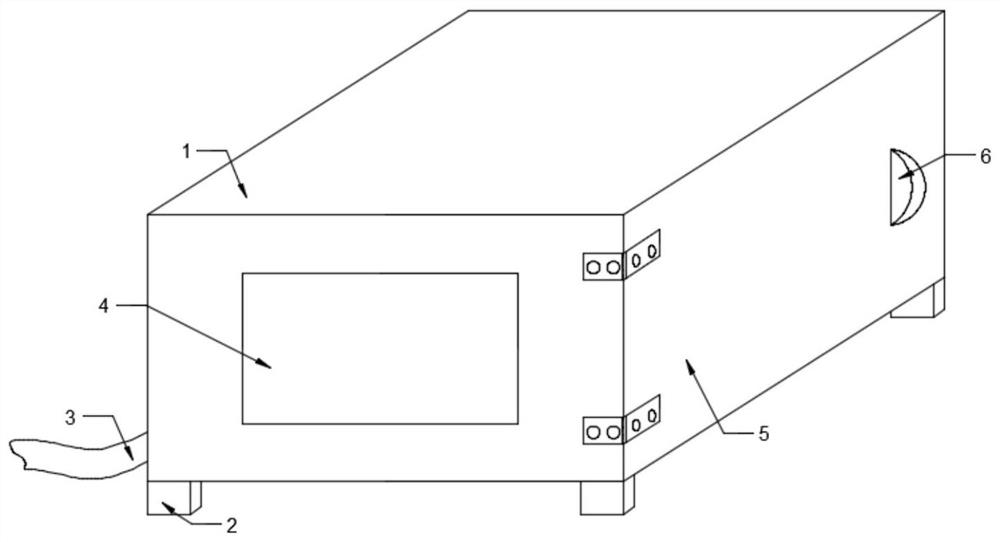

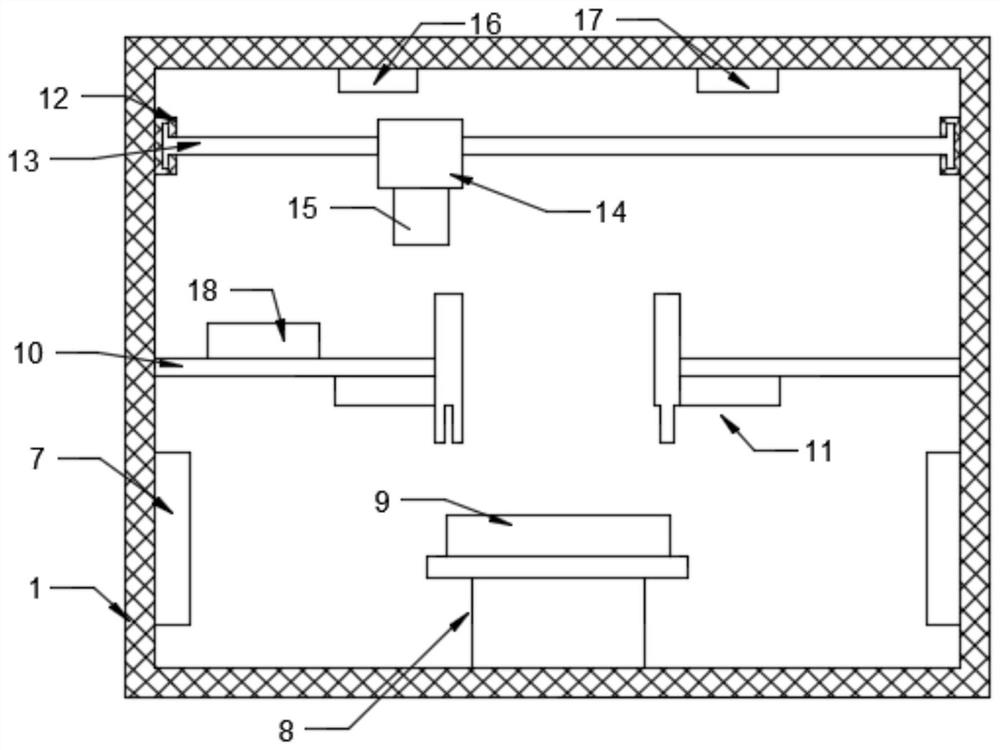

[0024] see figure 1 and figure 2 , in an embodiment of the present invention, a microbial sterilization inoculation device, comprising: a sterilization inoculation box 1, a foot block 2 is fixed at the bottom of the sterilization inoculation box 1, and a power cord is connected to the back side of the sterilization inoculation box 1 3. A control panel 4 is provided on one side of the sterilization inoculation box 1, a door 5 is hinged on the front side of the sterilization inoculation box 1, and a handle 6 is arranged on the door 5, and the sterilization inoculation box 1 An inoculation dish elevating mechanism 8 is fixedly installed at the inside bottom, an inoculation dish 9 is placed on the top of the inoculation dish elevating mechanism 8, and an ultraviolet germicidal lamp 7 is fixedly installed on the sterilization inoculation box 1 on both sides of the elevating mechanism. The middle part of the inoculation box 1 is fixedly equipped with a partition 10, the middle par...

Embodiment 2

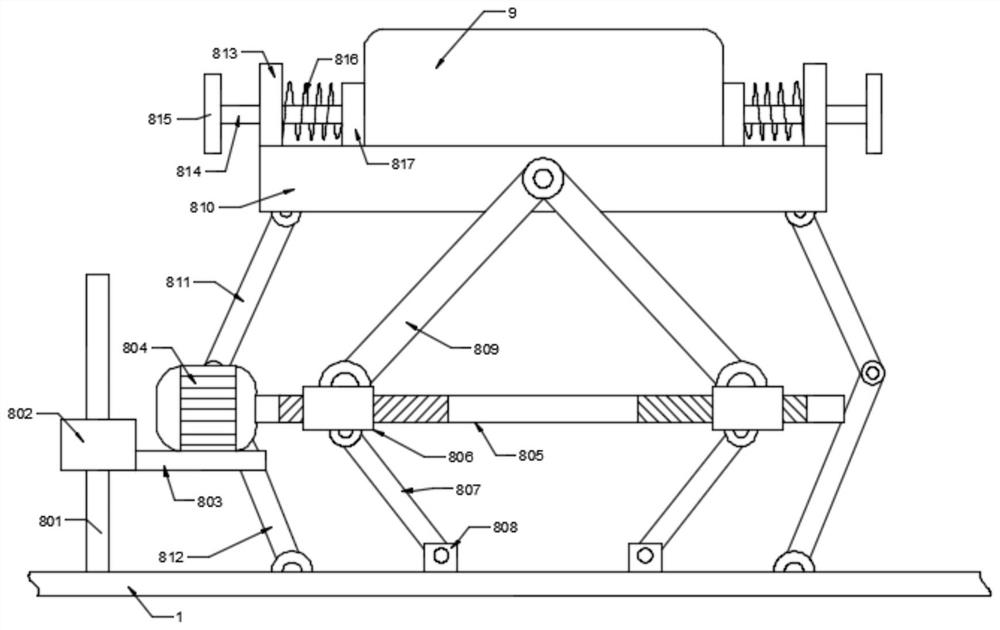

[0027] see image 3 , in this embodiment, the lifting mechanism 8 for the inoculation dish includes: a column 801, the column 801 is fixed on the inner bottom of the sterilization inoculation box 1, and a slider 802 is slidably arranged on the column 801, and the slider 802- A flat plate 803 is connected to the side, and a first motor 804 is fixedly installed on the flat plate 803. A threaded rod 805 is connected to one side of the first motor 804, and a threaded block 806 runs through the threaded rod 805. The threaded block 806 One side is rotatably connected with a first pole 807, the other end of the first pole 807 is rotatably mounted with a fixed block 808, and the fixed block 808 is fixed on the inner bottom of the sterilization inoculation box 1, and the other side of the threaded block 806 A second support rod 809 is rotatably connected, the other end of the second support rod 809 is rotatably mounted with a bearing plate 810, and both sides of the bearing plate 810 a...

Embodiment 3

[0030] see Figure 4, in this embodiment, the blocking mechanism 11 includes: a fixed platform 1101, the fixed platform 1101 is fixedly installed on the partition 10, a driving gear 1102 is arranged on the fixed platform 1101, and the upper part of the driving gear 1102 is arranged There is a connecting plate 1103, a blocking plate 1109 is fixedly connected to the lower side of the connecting plate 1103, and a rack 1108 is installed on the outside of the connecting plate 1103, and the rack 1108 is kept in mesh with the driving gear 1102. On the fixed table 1101 The first positioning column 1104 and the second positioning column 1105 are fixedly installed, and the positions corresponding to the first positioning column 1104 and the second positioning column 1105 on the connecting plate 1103 are respectively provided with a first chute 1106 and a second chute 1107, The first positioning post 1104 and the second positioning post 1105 are respectively disposed in the first sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com